Preparation method for proton exchange membrane fuel cell catalyst

A proton exchange membrane and fuel cell technology, applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of unfavorable catalyst industrial production, complex preparation process, difficult stabilizer removal, etc., to achieve safety and convenience Preparation efficiency, simple operation, and the effect of reducing catalyst agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

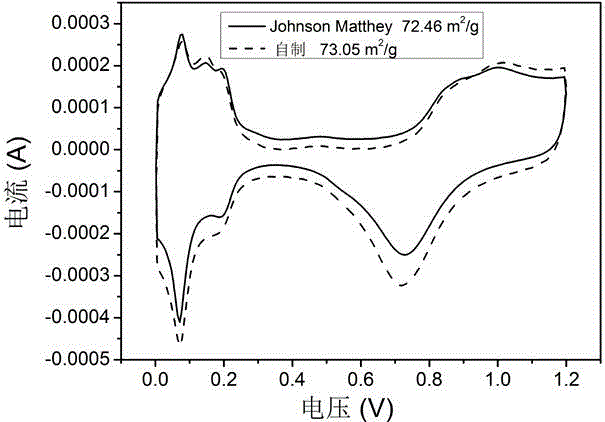

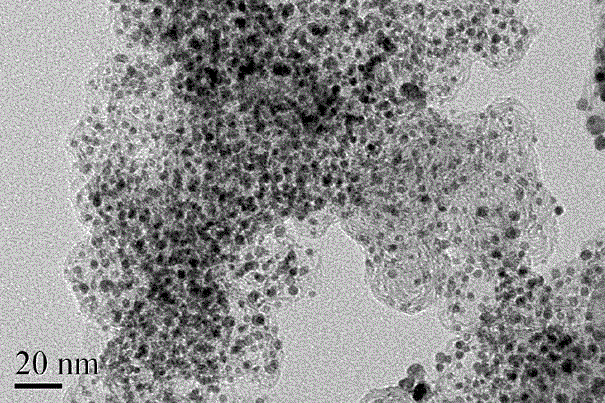

Embodiment 1

[0031] S1. Soak 1g of Vulcan XC-72R carbon black in a mixed solution of 3g of hydrogen peroxide and 3g of isopropanol, ultrasonically pretreat for 40min, with a power of 280W, filter under positive pressure, wash and dry in vacuum before use;

[0032] S2. Weigh 0.12 g of pretreated carbon black, add it to the sodium hydroxide solution, and ultrasonicate for 5 minutes;

[0033] S3, add 13g of deionized water, 28g of ethylene glycol, and 10.82g of chloroplatinic acid hexahydrate ethylene glycol solution with a mass fraction of 2% in turn in the beaker, and adjust the pH of the mixed slurry in the beaker to be 10;

[0034] S4, shear the slurry for 10 minutes, and ultrasonicate in an ice-water bath for 10 minutes to make the mixture uniform;

[0035] S5. Set the reaction temperature to 100°C, then heat with 700w microwave for 2.5min, cool the reaction solution to room temperature, add concentrated hydrochloric acid to adjust the pH value to 1, let it stand for 20min, filter, and w...

Embodiment 2

[0039] S1. Soak 1g of activated carbon in 3g of hydrogen peroxide and 9g of isopropanol, ultrasonically pretreat for 60min, filter under positive pressure, wash and dry in vacuum before use;

[0040] S2. Weigh 0.14 g of pretreated carbon black, add it to the sodium carbonate solution, and sonicate for 5 minutes;

[0041] S3. Add 12g deionized water, 21g ethylene glycol, and 8.12g mass fraction of 2% chloroplatinic acid hexahydrate ethylene glycol solution in the beaker, and adjust the pH of the mixed slurry in the beaker to 11;

[0042] S4, shear the slurry for 10 minutes, and ultrasonicate in an ice-water bath for 10 minutes to make the mixture uniform;

[0043] S5. Set the reaction temperature to 120°C, then heat with 800w microwave for 2 minutes, cool the reaction solution to room temperature, add concentrated hydrochloric acid to adjust the pH value to 2, let it stand for 20 minutes, filter, and wash repeatedly with deionized water until there is no chloride ion in the fil...

Embodiment 3

[0047] S1. Soak 1g of Vulcan XC-72R carbon black in a mixed solution of 3g of hydrogen peroxide and 4g of isopropanol, ultrasonically pretreat for 70min, filter under positive pressure, wash and dry in vacuum before use;

[0048] S2. Weigh 0.32 g of pretreated carbon black, add it to sodium hydroxide solution, and sonicate it in a 100 mL beaker for 8 min;

[0049]S3. Add 14g deionized water, 26g glycerol and 10.82g mass fraction of 2% chloroplatinic acid hexahydrate glycerin solution in the beaker in turn, and adjust the pH of the mixed slurry in the beaker to be 13;

[0050] S4, shear the slurry for 10 minutes, and ultrasonicate in an ice-water bath for 10 minutes to make the mixture uniform;

[0051] S5. Set the reaction temperature to 120°C, then heat with 700w microwave for 2.5min, cool the reaction solution to room temperature, add concentrated sulfuric acid to adjust the pH value to 2, let it stand for 20min, filter, and wash repeatedly with deionized water until there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com