Modified mordenite, preparation method and application thereof

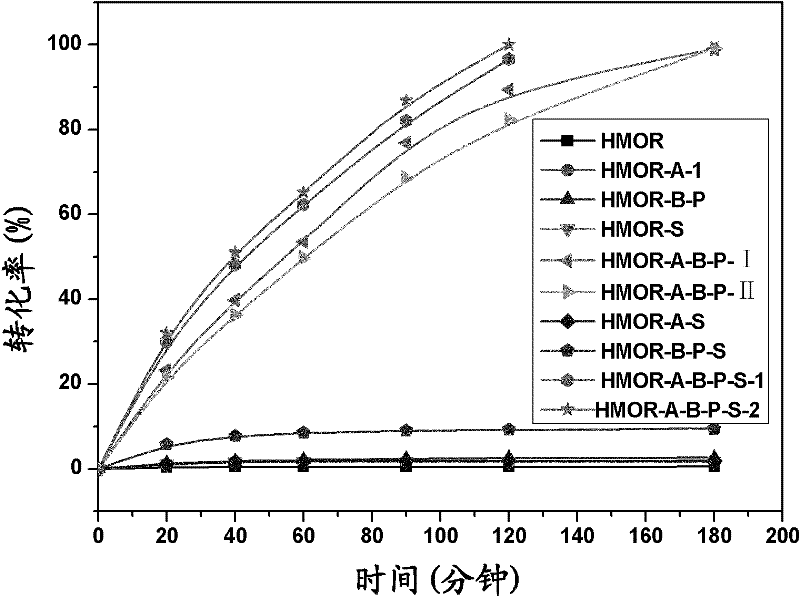

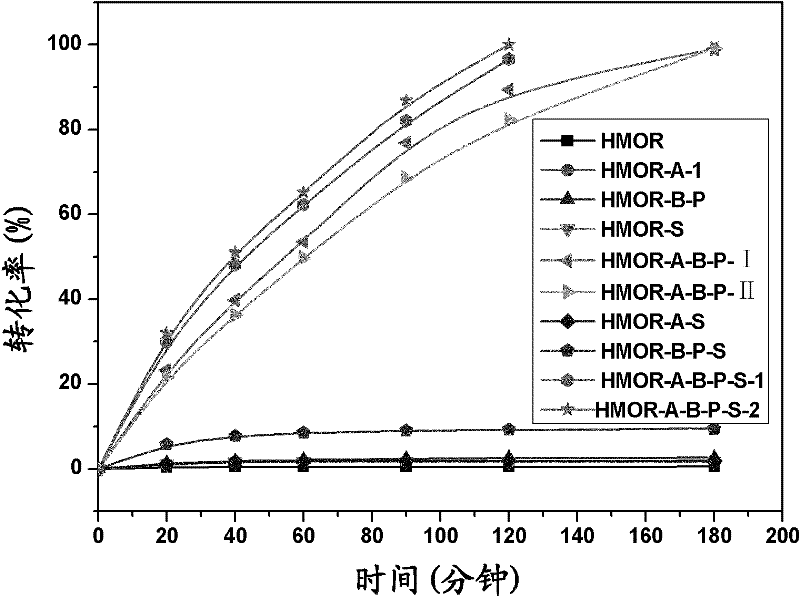

A mordenite and modification technology, applied in the field of preparing the modified mordenite, can solve the problems of small pores and cages, lack of connectivity, limited reaction and diffusion of macromolecules, etc., and achieve the effects of mild conditions and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Mix 34.0g of dried H-type mordenite (Zeolyst, USA, CBV 10A, Si / Al ratio=15, referred to as HMOR) with 400.0mL of 2.0mol / L HNO 3 (pH=1) reflux and stir at 100°C for 4 hours, filter with suction, wash with deionized water, filter with suction, dry in an oven at 120°C for 4 hours, and roast at 450°C for 2 hours to obtain 27.0 g of acid-treated Mordenite 1 (abbreviated as HMOR-A-1).

[0067] Stir 12.0g of HMOR-A-1 and 480mL of 0.2mol / L NaOH solution in a water bath at 80°C for 0.5 hours, filter with suction, wash with deionized water, filter with suction, dry at 120°C for 4 hours, and then dry at 450°C Calcined at the bottom for 2 hours to obtain 8.5 g of acid-treated and alkali-treated mordenite 1 (abbreviated as HMOR-A-B-1).

[0068] Mix the above HMOR-A-B-1 with 900mL of 1.0mol / L NH 4 NO 3The solution was stirred at 80°C for 1 hour, filtered with suction, washed with deionized water, filtered with suction, dried at 120°C for 4 hours, and roasted in a muffle furnace at...

Embodiment 2

[0071] With 12.0g dry H type mordenite (same as embodiment 1) and the HNO of 120.0mL 3.0mol / L 3 (pH=1) Stir at 80°C for 3 hours, filter with suction, wash with deionized water, filter with suction, dry in an oven at 100°C for 8 hours, and roast at 400°C for 4 hours to obtain 10.2 g of acid-treated Mordenite 2 (abbreviated as HMOR-A-2).

[0072] Stir the above HMOR-A-2 and 150mL 0.4mol / L NaOH solution in a water bath at 90°C for 1 hour, filter with suction, wash with deionized water, filter with suction, dry at 100°C for 8 hours, and then dry at 400°C Calcined for 4 hours, 6.9 g of acid-treated and alkali-treated mordenite 2 (abbreviated as HMOR-A-B-2) were obtained.

[0073] Mix the above HMOR-A-B-2 with 300mL of 1.0mol / L NH 4 NO 3 The solution was stirred at 80°C for 1 hour, filtered with suction, washed with deionized water, filtered with suction, dried at 100°C for 8 hours, and roasted in a muffle furnace at 400°C for 4 hours to obtain 6.5 g of acid-treated and alkali-tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com