Preparation method and application of starch-based mesoporous carbon with high specific surface area

A high specific surface area, starch-based technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of complex operation process, time-consuming, short cycle life of the template method, and achieve excellent electrochemical performance , Increase the specific surface area, increase the effect of mesopore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

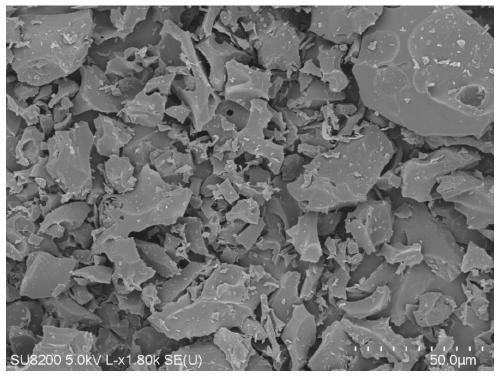

[0016] Add 3 g of industrial starch and 1 g of urea into 50 mL of deionized water and stir magnetically for 6 h. Then, dry the above suspension in an air-blast drying oven at 80 ° C for 12 h, take it out and place it in a tube furnace, and place it under the protection of argon. The pre-carbonization treatment was carried out at a temperature of 1 °C / min. The temperature was raised to 300 °C at a rate of 1 °C / min, and the temperature was kept at a constant temperature for 30 minutes. After cooling naturally to room temperature, the pre-carbonized product was obtained; : 1 mixed and added to 10mL of deionized water, stirred evenly, dried in a blast oven at 80°C for 12 hours, then taken out and placed in a tube furnace, and subjected to high-temperature activation treatment under the protection of argon at a temperature of 1°C / The heating rate was increased to 600°C for 30 minutes, and the temperature was kept constant for 30 minutes. After natural cooling to room temperature, t...

Embodiment 2

[0018] Add 2 g of industrial starch and 5 g of dicyandiamide into 100 mL of deionized water and stir magnetically for 3 h. Then, place the above suspension in a blast drying oven at 60°C for 8 h, take it out and place it in a tube furnace, and place it in a helium Carry out pre-carbonization treatment under air protection, the temperature is raised to 400°C at a heating rate of 3°C / min, and the temperature is kept at a constant temperature for 60min. After natural cooling to room temperature, the pre-carbonized product is obtained; Mixed at a ratio of 1:6 and added to 30mL of deionized water, stirred evenly, dried in a blast drying oven at 70°C for 8 hours, taken out and placed in a tube furnace, and subjected to high-temperature activation treatment under the protection of helium at a temperature of 3 The heating rate of ℃ / min was raised to 800 ℃, the temperature was kept constant for 60 minutes, and after natural cooling to room temperature, the activated product was obtained...

Embodiment 3

[0020] Add 5 g of industrial starch and 7 g of melamine into 70 mL of deionized water and stir magnetically for 24 h. Then, put the above suspension in a blast drying oven at 100 ° C for 16 h, take it out and place it in a tube furnace, and place it under the protection of argon. Carry out pre-carbonization treatment at a temperature of 15°C / min to 500°C at a rate of 15°C / min, keep the temperature for 50 minutes, and cool to room temperature naturally to obtain a pre-carbonized product; : 0.5 mixed and added to 70mL of deionized water, stirred evenly, dried in an 80°C blast drying oven for 16 hours, taken out and placed in a tube furnace, and subjected to high-temperature activation treatment under the protection of argon at a temperature of 15°C / The heating rate was raised to 1100°C, kept at a constant temperature for 50 minutes, and after natural cooling to room temperature, the activated product was obtained; then the obtained activated product was added to 150 mL of hydroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com