A method of preparing a hierarchical porous carbon material as a supercapacitor electrode material

A supercapacitor, hierarchical porous technology, applied in hybrid capacitor electrodes, carbon preparation/purification, etc., can solve the problems of complex methods, long time-consuming, poor pore-forming effect, etc., achieve simple process, good rectangularity, avoid The effect of de-template process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

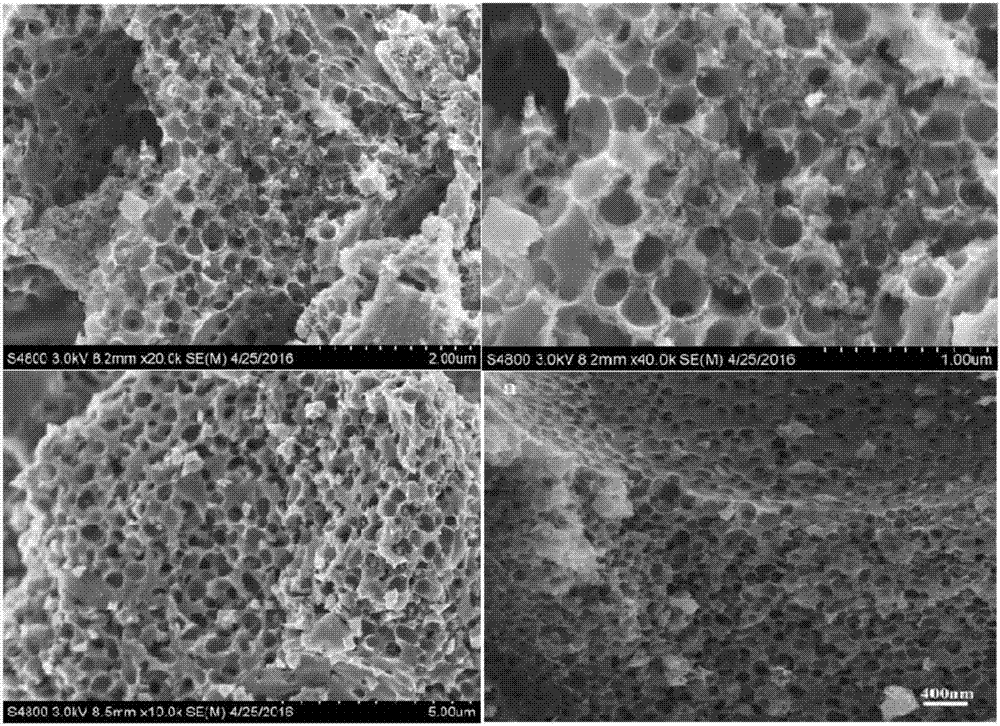

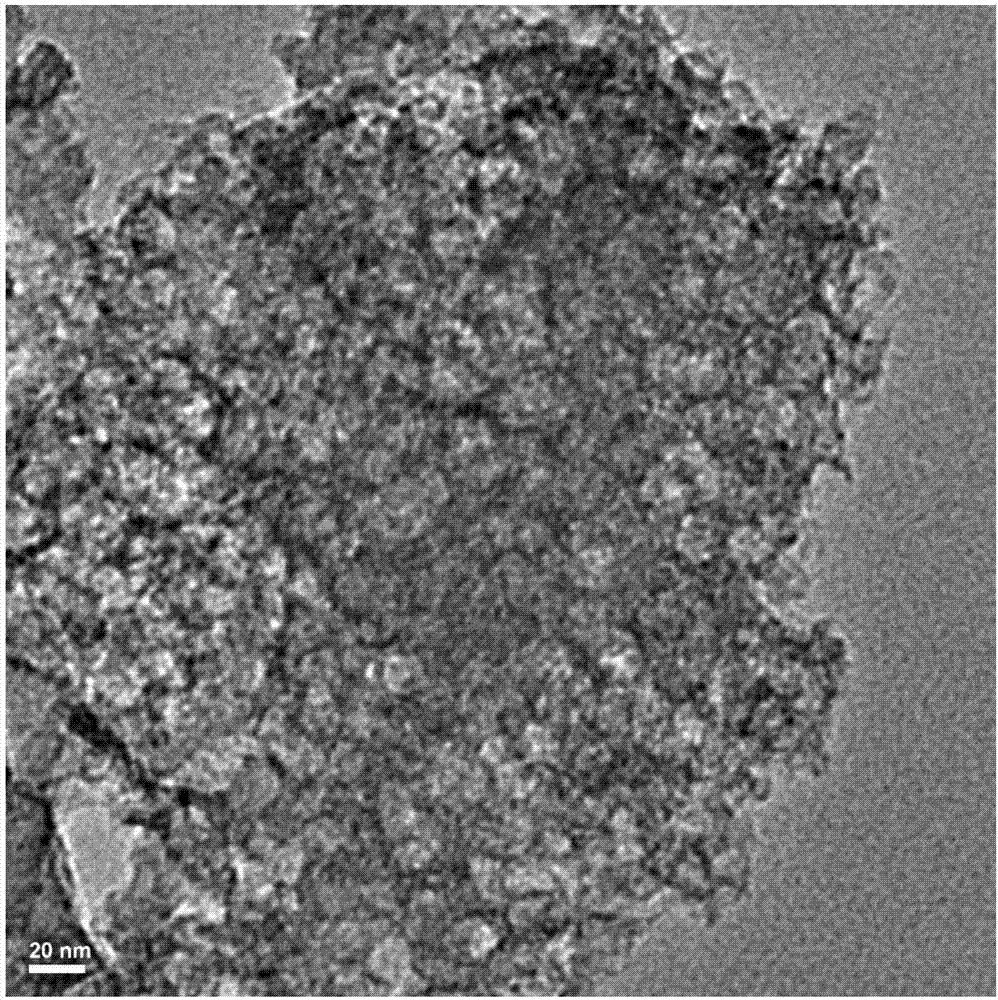

[0032] Measure 1.4mL of formaldehyde with a mass percentage of 37%, 2mL 0.005g mL -1 Weigh 1g of resorcinol, add distilled water to make 75mL mixed solution, stir evenly, and react at 85°C for 3h to obtain orange-yellow phenolic resin prepolymer (RF) solution; weigh 0.25g of acrylamide, 0.0054g of N,N'-methylenebisacrylamide, prepared as 20mL monomer solution. After mixing the above two solutions evenly, transfer them to a 100mL round-bottomed flask, stir and ventilate nitrogen for 30 minutes to exhaust the oxygen, then add the initiator ammonium persulfate and sodium bisulfite (the amount of both is 1% of the molar amount of acrylamide) 2%) as a redox initiator for acrylamide polymerization, reacted at 30° C. for 12 hours under a nitrogen atmosphere to obtain a light yellow gel, at which time acrylamide self-polymerized in a phenolic resin solution to form polyacrylamide (PAM). The gel was placed in an autoclave at 120° C. for 24 hours, so that the phenolic resin was complet...

Embodiment 2

[0035] Measure 1.4mL of formaldehyde with a mass percentage of 37%, 2mL 0.005g mL -1 Weigh 1g of resorcinol, add distilled water to make 75mL mixed solution, stir evenly, and react at 85°C for 3h to obtain orange-yellow phenolic resin prepolymer (RF) solution; weigh 0.5g of acrylamide, 0.0108g of N,N'-methylenebisacrylamide, prepared as 20mL monomer solution. After the above two solutions were mixed evenly, they were transferred to a 100mL round-bottomed flask, stirred and fed with nitrogen for 30 minutes to exhaust the oxygen, then added ammonium persulfate and sodium bisulfite (the initiator was 2% of the molar weight of the monomer) as propylene The redox initiator for amide polymerization reacts at 30°C for 12 hours under a nitrogen atmosphere to obtain a light yellow gel. At this time, the self-polymerization of acrylamide in the phenolic resin solution is completed to form polyacrylamide (PAM). The gel was placed in an autoclave at 120° C. for 24 hours, so that the phen...

Embodiment 3

[0037] Measure 1.4mL of formaldehyde with a mass percentage of 37%, 2mL 0.005g mL -1 Sodium carbonate solution, weigh 1g resorcinol, add distilled water to prepare 75mL mixed solution, stir evenly, react at 85°C for 3h to obtain orange-yellow phenolic resin prepolymer (RF) solution; weigh 1g acrylamide, 0.0216 g N,N'-methylenebisacrylamide, configured as a 20mL monomer solution. After the above two solutions were mixed evenly, they were transferred to a 100mL round-bottomed flask, stirred and fed with nitrogen for 30 minutes to exhaust the oxygen, then added ammonium persulfate and sodium bisulfite (the initiator was 2% of the molar weight of the monomer) as propylene The redox initiator for amide polymerization reacts at 30°C for 12 hours under a nitrogen atmosphere to obtain a light yellow gel. At this time, the self-polymerization of acrylamide in the phenolic resin solution is completed to form polyacrylamide (PAM). The gel was placed in an autoclave at 120° C. for 24 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com