Method for preparing multistage-hole ZSM-5 molecular sieve

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of high production cost of molecular sieve, reduced dosage of template agent, large mesopore volume, etc. Achieve the effect of avoiding partial damage of crystal structure, improving service life and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0037] Specific embodiment one: the method for preparing multi-stage porous ZSM-5 molecular sieve in this embodiment is carried out according to the following steps: add tetrapropyl ammonium hydroxide and deionized water to aluminum isopropoxide, stir evenly, become A solution; mix ethyl orthosilicate and deionized water evenly to prepare solution B. Add solution B slowly to solution A under stirring, stir vigorously for 3 hours to make a mixed gel, the molar composition of the mixed gel is Al 2 o 3 : SiO 2 =1:30~100, TPAOH:SiO 2 =0.25~0.40,H 2 O: SiO 2 =8~12. Transfer the mixed gel into a stainless steel airtight reaction kettle with a polytetrafluoroethylene liner, crystallize at a temperature of 100-140°C for 3-12 hours, then cool to room temperature, and make a seed crystal to be prepared use.

[0038] Dissolve sodium metaaluminate in deionized water to make solution A; weigh silica sol, NaOH and deionized water, stir well to make solution B; add solution A to solut...

specific Embodiment approach 2

[0039] Specific embodiment two: the method for preparing multi-stage porous ZSM-5 molecular sieve in the present embodiment is carried out according to the following steps:

[0040] Add 0.071g of aluminum isopropoxide to 5.0g of tetrapropylammonium hydroxide and 0.261g of deionized water, stir evenly, and prepare A solution; weigh 3.691g of tetraethyl orthosilicate and slowly add it to In solution A, stir vigorously for 3 hours to form a mixed gel, and the molar composition of the mixed gel is Al 2 o 3 : SiO 2 =1:50, TPAOH:SiO 2 =0.357,H 2 O: SiO 2 = 10.8. The above mixed gel was sealed in a stainless steel reactor with a polytetrafluoroethylene liner, crystallized at 140° C. for 9 hours, then taken out and cooled to room temperature to obtain seed crystals.

[0041] To 20g of silica sol (SiO 2 content is 30%) and 0.217g sodium metaaluminate, add 31g water, weigh 0.75gNaOH and 16.75g deionized water and add in silica sol, stir well, make A solution; 2 o 3 : SiO 2 =1:...

specific Embodiment approach 3

[0042] Specific embodiment three: this embodiment prepares ZSM-5 molecular sieve according to the method for specific embodiment two, difference is that the amount of adding 3-(phenylamino) propyl trimethoxysilane accounts for SiO 2 5% of the amount, other steps and parameters are the same as in the second embodiment.

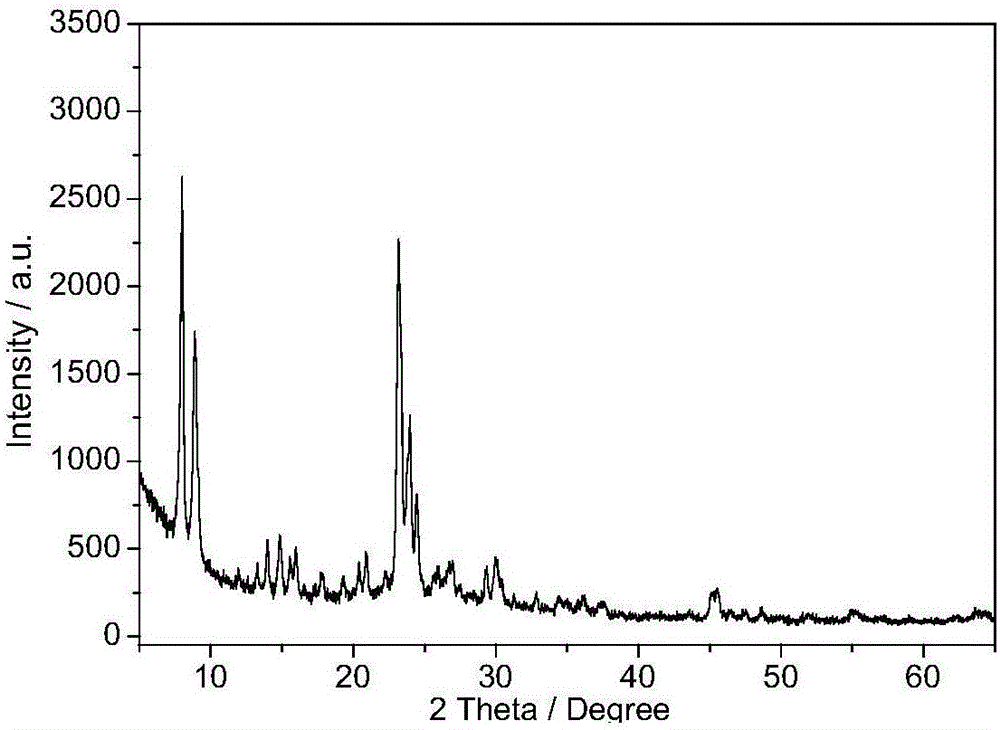

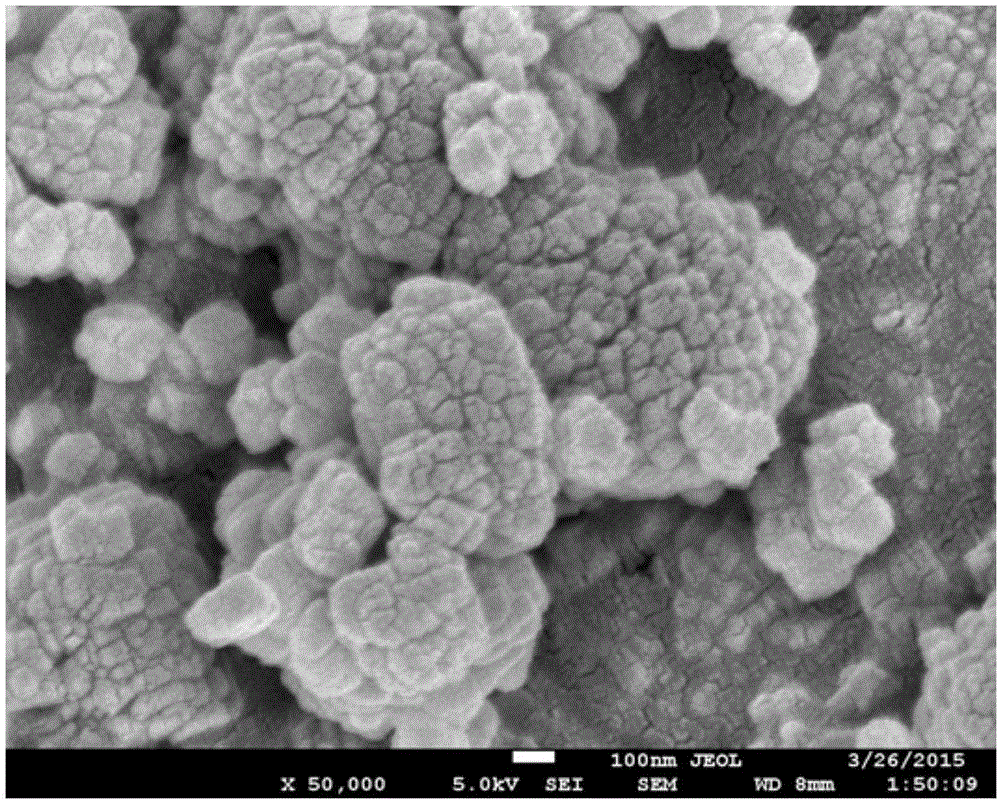

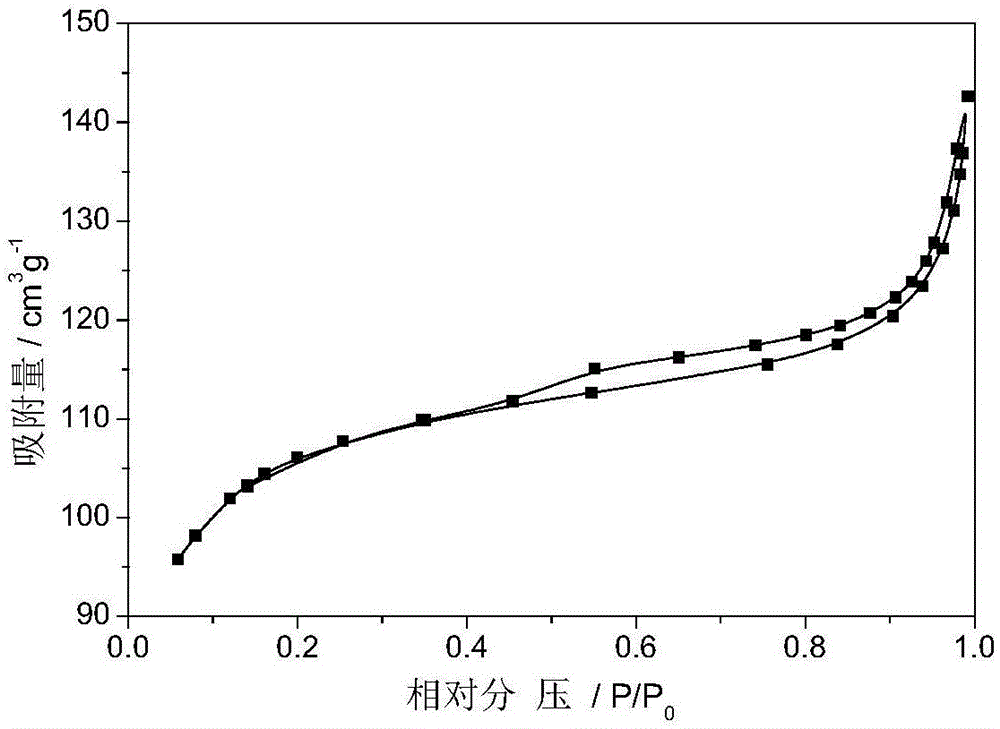

[0043] According to the method of the present embodiment, the ZSM-5 molecular sieve whose addition amount of organic silicon reagent can be obtained is 5%, is denoted as ZSM-5 (5), and its XRD spectrogram, SEM photo and N 2 Adsorption and desorption isotherms are shown in Figure 4 , Figure 5 and Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com