Catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problem of low yield of BTX

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

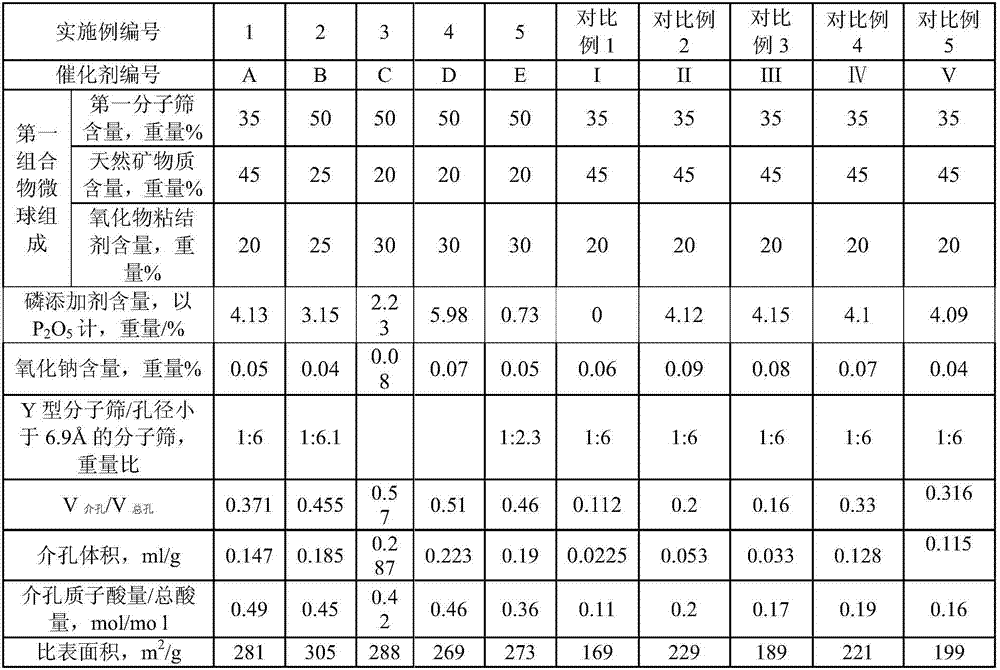

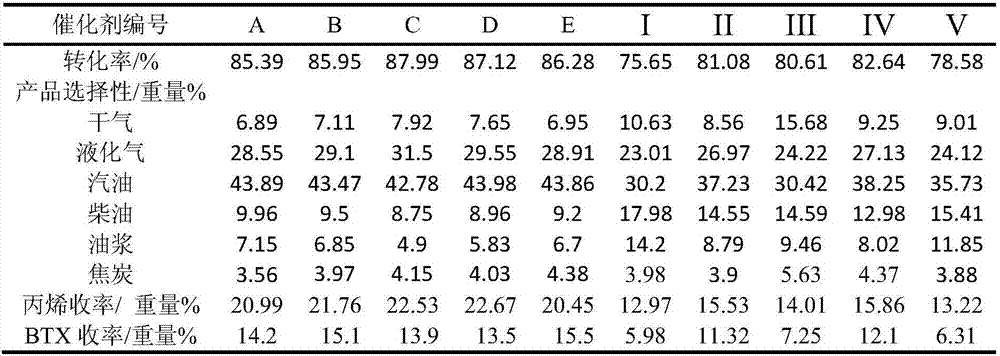

[0051] The preparation method of the catalytic cracking catalyst provided by the present invention includes mixing and beating natural minerals, the first molecular sieve, an oxide binder such as oxide sol and / or oxide gel, and water. Based on the total weight of the catalytic cracking catalyst, the amount of each component is such that the final obtained catalytic cracking catalyst contains 5% by weight to 65% by weight of natural minerals, 10% by weight to 60% by weight of oxides and 24% by weight % to 75% by weight of the first molecular sieve. More preferably, the amount of each component is such that the composition of the final catalyst includes: the natural mineral content is 5% to 50% by weight on a dry basis, such as 8 to 45% by weight, and the content of the first molecular sieve on a dry basis 30% to 65% by weight, such as 30 to 55% by weight, the content of the oxide binder in terms of oxides is 15 to 55% by weight, such as 20 to 50% by weight or 25 to 45% by weigh...

Embodiment 1

[0074] 267g aluminum sol is mixed with 180g kaolin, and it is mixed with decationized water into a slurry with a solid content of 30% by weight. After stirring for 2 hours, 15gUSY, 45gβ molecular sieves and 45gZRP-1 molecular sieves are added to form a composition slurry (with a solid content of 35% % by weight), stirred evenly, spray-dried to make composition microspheres, and then calcined the composition microspheres at 500° C. for 2 hours to obtain the first composition microspheres A1.

[0075] Take 200 g of the first composition microspheres A1 (dry basis mass, the same below) prepared above, add water and beat to obtain a slurry with a solid content of 10% by weight, add 15.1 g of high alkali sodium metaaluminate solution (Na 2 O is 290g / L, Al 2 o 3 40g / L, the solution density is 1.353g / mL), heated up to 50°C and stirred at constant temperature for 0.5h, filtered and washed to neutral (washing to neutral means that the washing liquid after washing is neutral, pH6~8); ...

Embodiment 2

[0077] Mix 333.3g of aluminum sol with 100g of montmorillonite, and use decationized water to prepare it into a slurry with a solid content of 21.5% by weight. After stirring for 0.5 hours, add 20g of REY molecular sieve and 130g of ZSM-5 molecular sieve, and stir evenly to form the first combination The slurry (solid content: 35% by weight) was spray-dried to make composition microspheres, and then the composition microspheres were calcined at 350° C. for 2 hours to obtain the first composition microspheres B1.

[0078] Take 200 g of the first composition microspheres B1 (mass on a dry basis) prepared above, add water to prepare the first composition microsphere slurry with a solid content of 10% by weight, add 20.5 g of NaOH (purity: 96%), heat up to 70 ° C and stir at a constant temperature 0.3h, filter, wash to neutrality; Add water to the filter cake and beating to obtain a slurry with a solid content of 10% by weight, add 25.1g oxalic acid during stirring, then add 38g hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total specific surface area | aaaaa | aaaaa |

| Surface | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com