Modified method of Y-type molecular sieve

A molecular sieve and modification technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problem of small mesopore volume of the product Y-type molecular sieve, insignificant increase in mesopore, and large environmental pollution. problems, to achieve the effect of being beneficial to catalytic cracking, easy to control the operation process, and easy to control the reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Mix NaY, aluminum sulfate octadecahydrate, and water in a mass ratio of 3.5:2:4, then add ethanol to the reaction system, and the mass ratio of ethanol to water is 1:1. The reaction mixture was reacted at 185°C for 1d. After the reaction was completed, it was filtered, washed, and dried at 80°C to obtain GCCP-1-1.

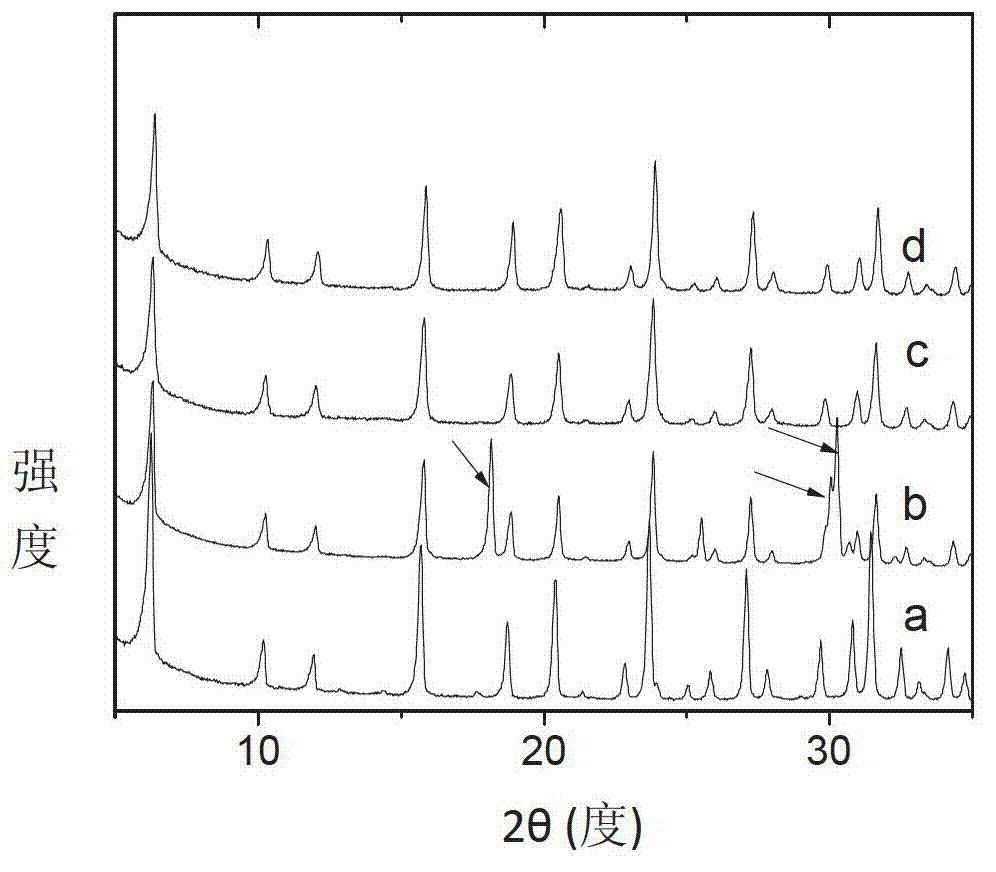

[0058] (2) GCCP-1-1: NaOH: H 2 O was mixed in a mass ratio of 1:0.1:10, stirred at 80°C for 1 hour, washed and filtered, and dried at 80°C, which was designated as GCCP-2-1(0), and GCCP-2- 1(0):NaOH:H 2 O was mixed in a mass ratio of 1:0.1:10, stirred at 80°C for 1 hour, washed and filtered, dried at 80°C, calcined at 550°C, and designated as GCCP-2-1. The relative crystallinity of the Y-type molecular sieve determined by X-ray diffraction is 70%, the silicon-aluminum ratio of the skeleton is 7.0, and the final total solid phase yield is 77.3%. The X-ray spectrum of GCCP-1-1 is as follows figure 1 (b), figure 1 The miscellaneous peaks marked by the...

Embodiment 2

[0060] (1) The first step of Example 2 is the same as Example 1 to obtain GCCP-1-1.

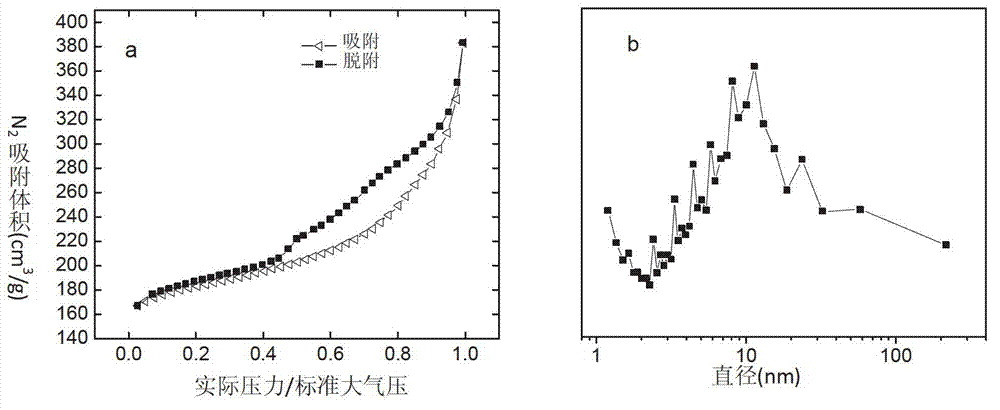

[0061] (2) GCCP-1-1: NaOH: H 2 O was mixed in a mass ratio of 1:0.2:10, stirred at 80°C for 1 hour, washed and filtered, dried at 80°C, calcined at 550°C, and designated as GCCP-2-2. The relative crystallinity of the Y-type molecular sieve measured by X-ray diffraction is 70%, the skeleton silicon-aluminum ratio is 6.8, and the final total solid phase yield is 76.7%. The X-ray spectrogram of GCCP-2-2 is as follows figure 1 (d), shown N 2 Adsorption-desorption curve (a) and BJH adsorption pore size distribution curve (b) see image 3 , the adsorption data are shown in Table 1.

Embodiment 3

[0063] (1) Mix NaY, aluminum sulfate octadecahydrate, and water in a mass ratio of 4.35:2:4, then add ethanol to the reaction system, and the mass ratio of ethanol to water is 0.8:1. The reaction system was reacted at 185° C. for 1 day. After the reaction was completed, it was filtered, washed, and dried at 80°C to obtain GCCP-1-3.

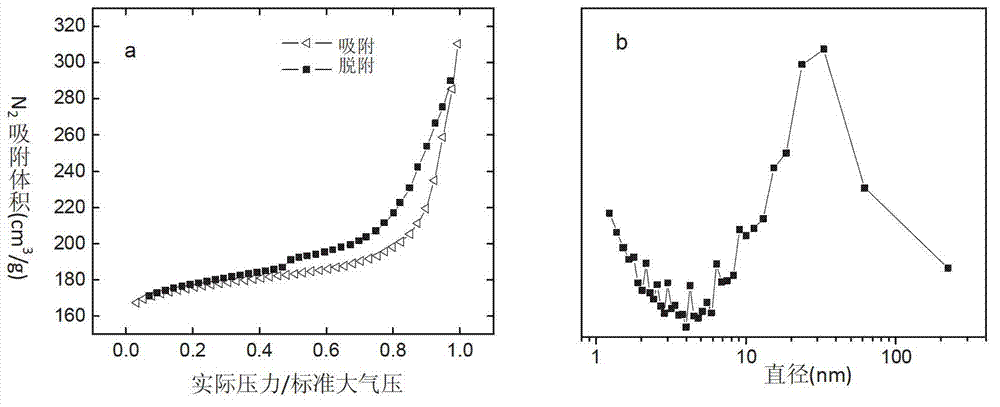

[0064] (2) GCCP-1-3: NaOH: H 2 O was mixed according to the mass ratio of 1:0.2:10, stirred at 80°C for 1 hour, washed and filtered, dried at 80°C, calcined at 550°C, recorded as GCCP-2-3, determined by X-ray diffraction The relative crystallinity of the Y-type molecular sieve is 83%, the silicon-aluminum ratio of the skeleton is 6.52, and the final total solid phase yield is 80.7%. N shown in GCCP-2-3 2 Adsorption-desorption curve (a) and BJH adsorption pore size distribution curve (b) see Figure 4 , the adsorption data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com