Preparation method and applications of modified ZSM-5 molecular sieve for high-selective preparation of propylene from methanol and dimethyl ether

A ZSM-5, high-selectivity technology, applied in molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as poor stability and easy carbon deposition, and achieve extended catalytic life, simple operation, and controllability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

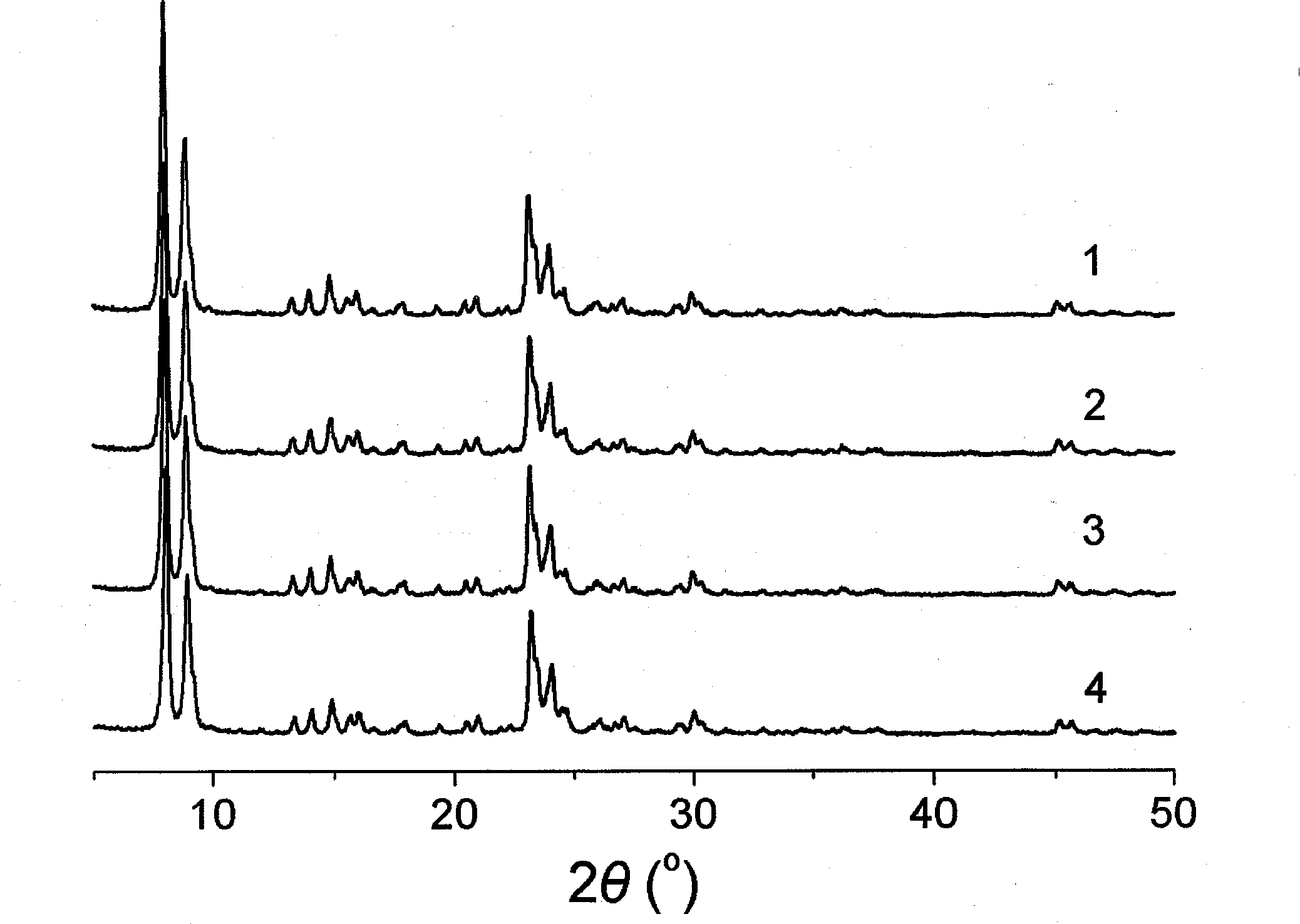

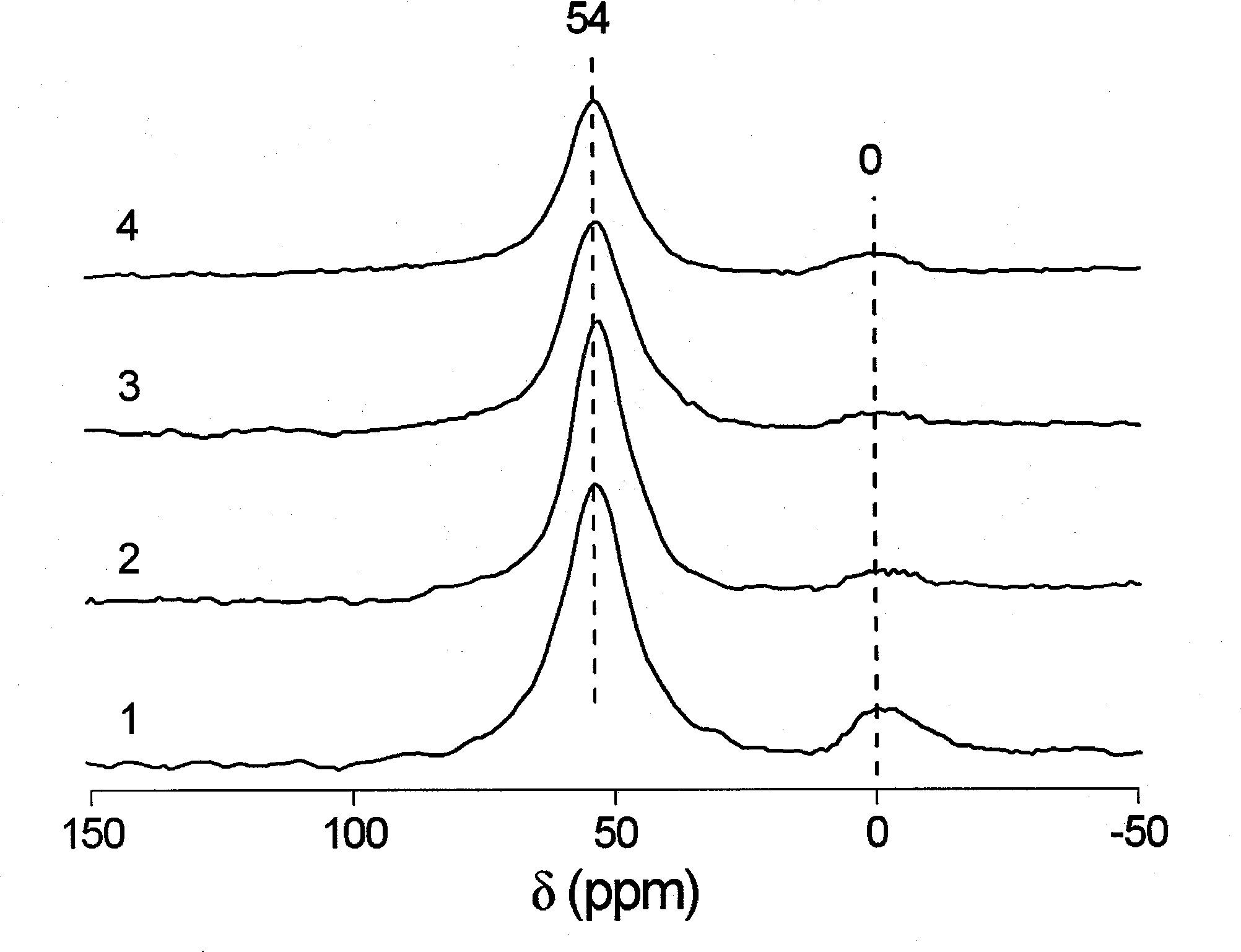

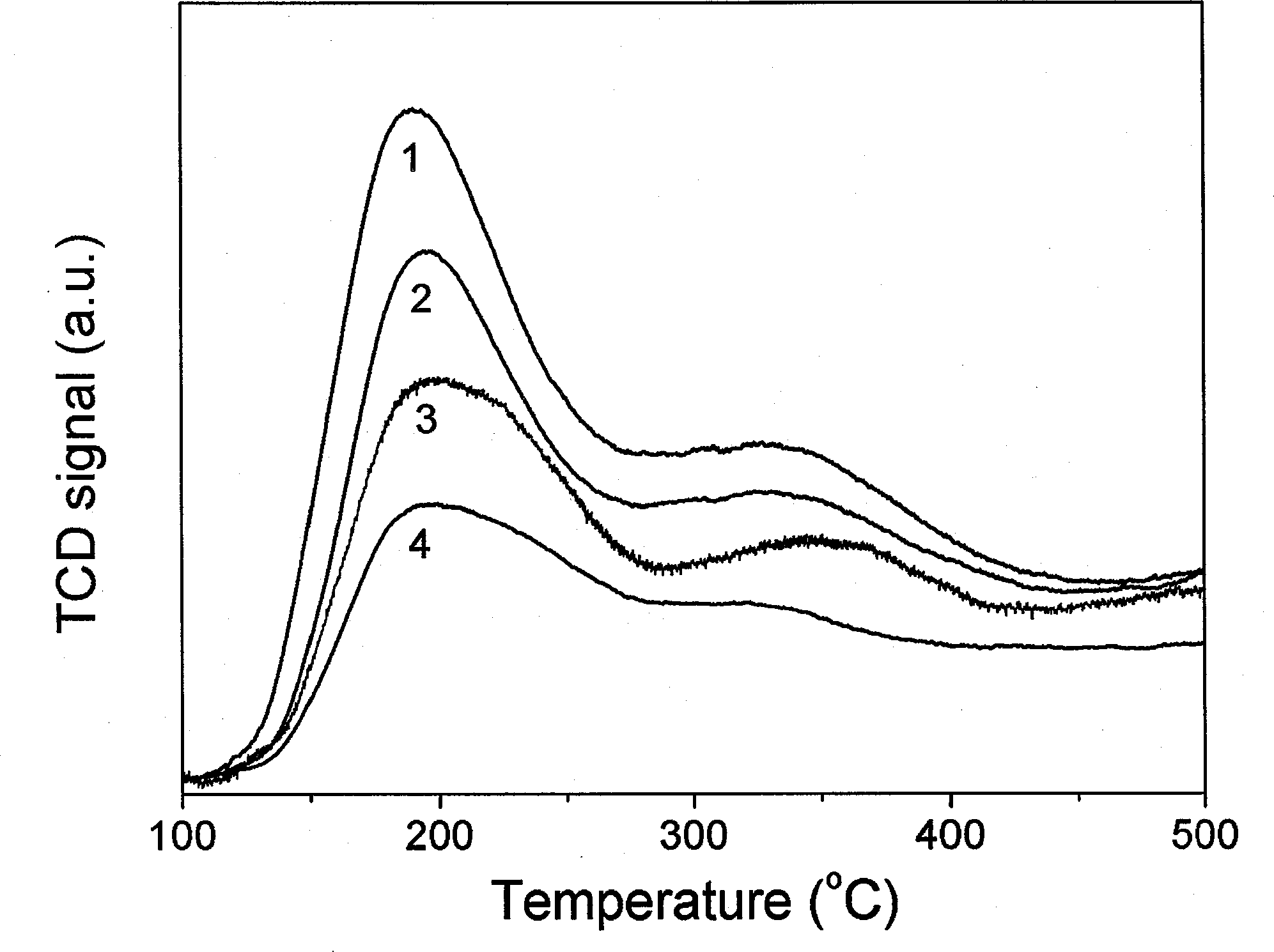

[0021] The silicon-aluminum ratio is (SiO 2 / Al 2 o 3 ) is 100, and the ZSM-5 molecular sieve with a grain size of about 200 nanometers is calcined at 500° C. for 5 hours. Then exchange with 1 mol / l ammonium chloride or ammonium nitrate at 90°C for 2 hours. After washing, filtering and drying, use 0.1, 0.2, 0.5, 0.8, 1.0 mol / L ammonium fluorosilicate solution to reflux at 30°C, 60°C, 90°C for 2 hours or 6 hours, then wash with deionized water, filter and dry Afterwards, they were calcined at 500°C for 5 hours to obtain a series of modified HZSM-5 catalysts.

Embodiment 11

[0023] The modified catalyst modified in Example 1-10 was pressed into tablets, sieved into 20-40 meshes, and the reaction temperature was 470°C, normal pressure, methanol partial pressure was 50kPa, and methanol space velocity was 3. Carry out methanol-to-propylene reaction Evaluation, the results of the reaction are listed in Table 1.

[0024] Table 1 Methanol to propylene reaction performance of modified ZSM-5 zeolite catalyst

[0025]

[0026]

[0027] a The reaction time to maintain the conversion rate of methanol above 90%.

Embodiment 12-20

[0029] The silicon-aluminum ratio is (SiO 2 / Al 2 o 3 ) is 60, 200, 300, 500, and the grain size is about 1000 nanometers

[0030] Baking at 500°C for 5 hours. Then, it was exchanged with 1.0 mol / liter hydrochloric acid at 90° C. for 2 hours. After washing, filtering and drying, reflux with 0.1, 0.2, 0.5, 0.8, 1.0 mol / liter ammonium fluorosilicate solution at 30°C, 60°C, and 90°C for 6 hours, then wash with deionized water, filter and dry to obtain a series of modified products. Sexual ZSM-5 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com