Method for removing refractory organic matters in industrial wastewater

A technology for refractory organic matter and industrial wastewater, which is applied in the field of wastewater treatment and can solve the problems of limiting the removal efficiency of activated carbon for refractory organic matter and the complex water quality of industrial wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

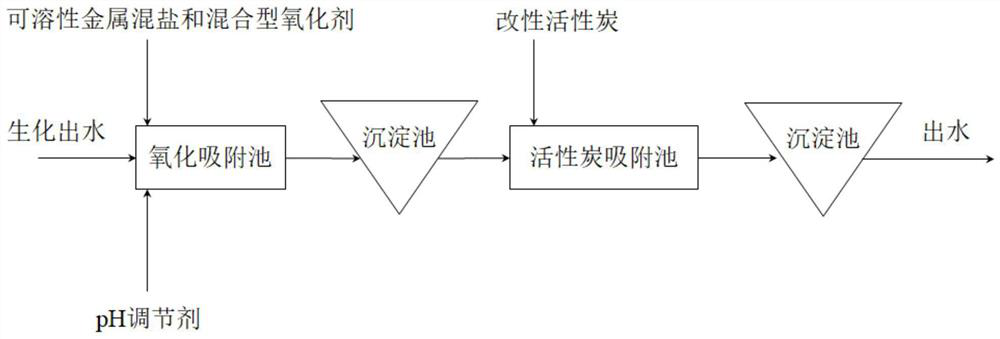

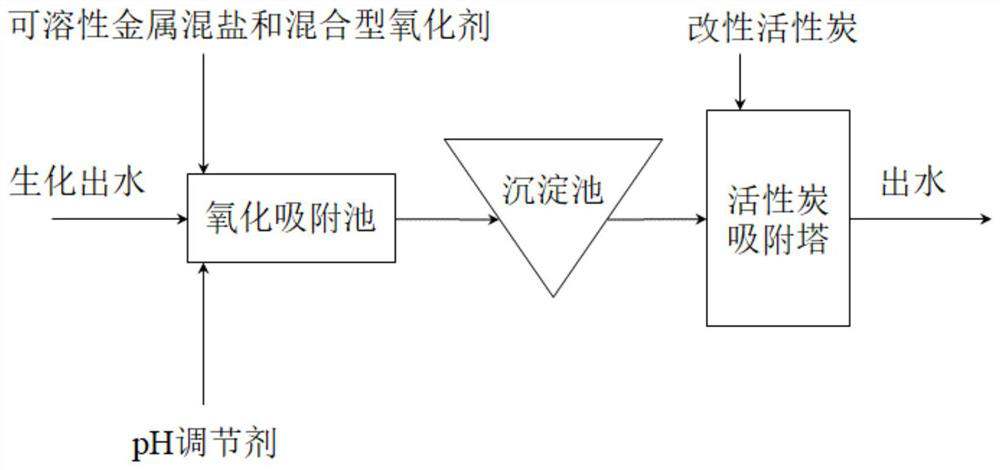

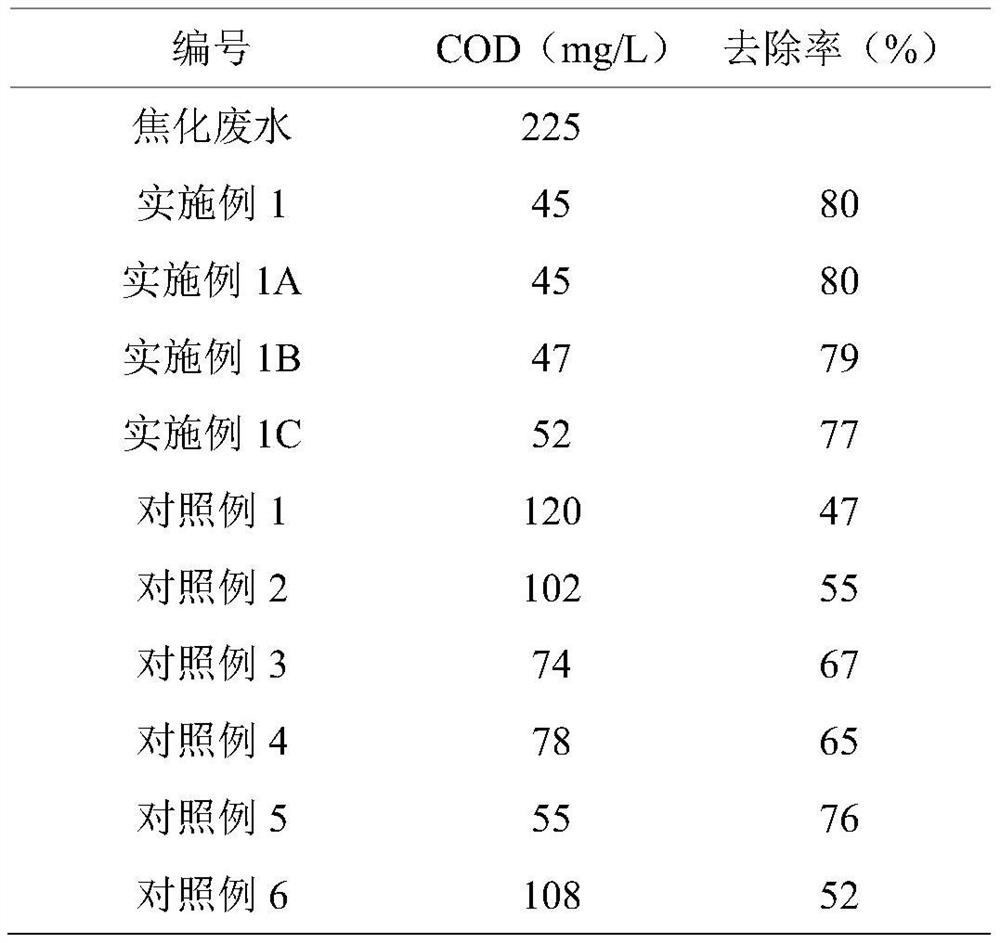

[0091] Example 1: Biochemical effluent treatment of coking wastewater by oxidation adsorption technology-activated carbon adsorption combined process

[0092] 1. Prepare compound oxidants and compound soluble metal salts

[0093] 1-1, the H 2 o 2 , sodium hypochlorite and sodium persulfate (both pure substances) are mixed uniformly to prepare a composite oxidizer for subsequent use, wherein the H in the composite oxidant 2 o 2 , The molar ratio of sodium hypochlorite and sodium persulfate is 1:0.046:0.043, H 2 o 2 , The mass ratio of sodium hypochlorite and sodium persulfate is 1:0.1:0.3;

[0094] Sodium hypochlorite in composite oxidizer can use potassium hypochlorite, hypochlorous acid to replace; Sodium persulfate can use potassium persulfate, ammonium persulfate to replace; In the embodiment of the present invention, H 2 o 2 , the mol ratio of sodium hypochlorite and sodium persulfate except being 1: 0.046: 0.043, other ratios such as 1: (0.027-0.456): (0.009-0.143)...

Embodiment 1A

[0122] Example 1A: Biochemical effluent treatment of coking wastewater by oxidation adsorption technology-activated carbon adsorption combined process

[0123] 1. Prepare compound oxidants and compound soluble metal salts

[0124] 1-1, the H 2 o 2 , sodium hypochlorite and sodium persulfate are mixed evenly according to the mass ratio of 1:0.2:0.06, and prepared into a composite oxidant for standby use, that is, H in the composite oxidant 2 o 2 , hypochlorite (ClO - ), persulfate (S 2 o 8 2- ) in a molar ratio of 1:0.091:0.009;

[0125] 1-2, the soluble metal salt FeSO 4 、CuSO 4 , MnSO 4 、CoSO 4 , CaCl 2 and MgSO 4 According to the mass ratio of 100: 0.5: 30: 0.5: 25: 0.1, it is mixed to make a composite soluble metal salt, which is ready for use, that is, Fe in the composite metal salt 2+ 、Cu 2+ , Mn 2+ 、Co 2+ , Ca 2+ , Mg 2+ The molar ratio is 100:0.475:30.2:0.490:34.2:0.127;

[0126] 2. In-situ oxidative degradation-adsorption treatment

[0127] Except ...

Embodiment 1B

[0131] Example 1B: Biochemical effluent treatment of coking wastewater by oxidation adsorption technology-activated carbon adsorption combined process

[0132] 1. Prepare compound oxidants and compound soluble metal salts

[0133] 1-1, the H 2 o 2 , sodium hypochlorite and sodium persulfate are mixed evenly according to the mass ratio of 1:0.06:1, and prepared into a composite oxidant for standby use, that is, H in the composite oxidizer 2 o 2 , hypochlorite (ClO - ), persulfate (S 2 o 8 2- ) The molar ratio is 1:0.027:0.143;

[0134] 1-2, the soluble metal salt FeSO 4 、CuSO 4 , MnSO 4 、CoSO 4 , CaCl 2 and MgSO 4 Mix according to the mass ratio of 100:50:0.2:15:0.4:10 to prepare a composite soluble metal salt for future use, that is, Fe in the composite metal salt 2+ 、Cu 2+ , Mn 2+ 、Co 2+ , Ca 2+ , Mg 2+ The molar ratio is 100:47.5:0.201:14.7:0.548:12.7;

[0135] 2. In-situ oxidative degradation-adsorption treatment

[0136] Except that the ratio of the CO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com