Preparation method of hollow molecular sieve catalyst and application of hollow molecular sieve catalyst in preparation of high-density aviation fuel by hydrogenation of polycyclic aromatic hydrocarbon

A technology of fused-ring aromatics and molecular sieves, applied in molecular sieve catalysts, aromatics hydrogenation refining, chemical instruments and methods, etc., can solve the problems of low catalytic activity, low accessibility, and weak synergistic effect of fused-ring aromatics hydrogenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

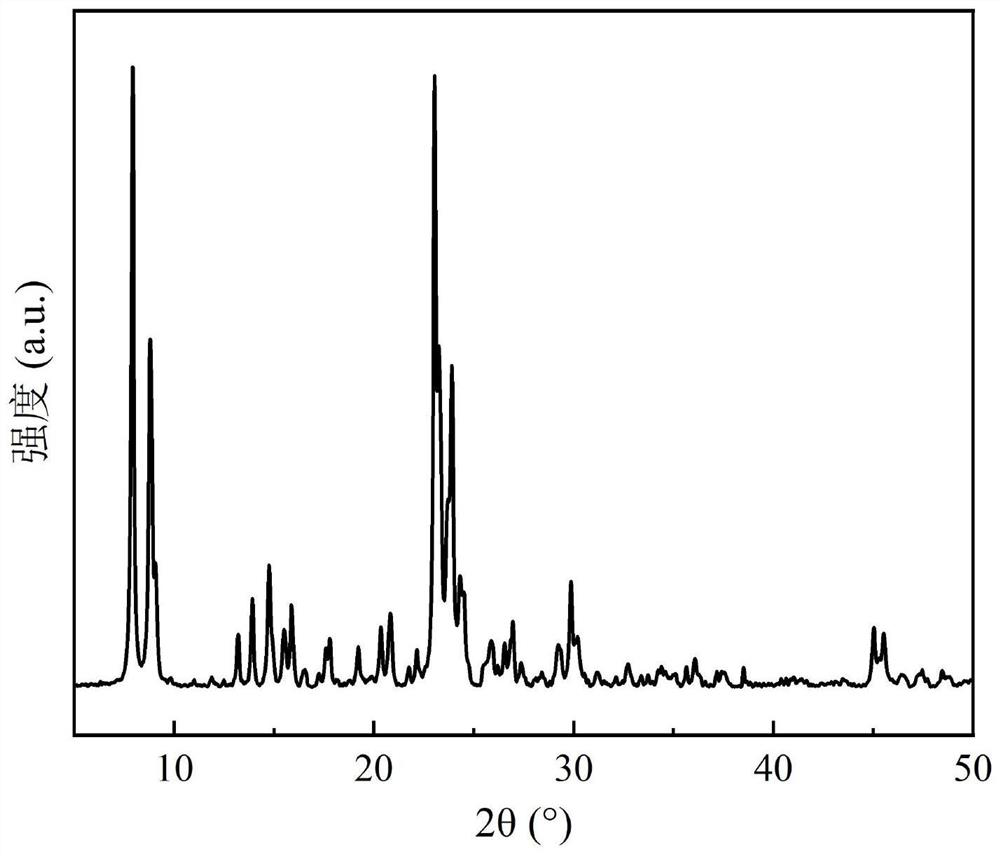

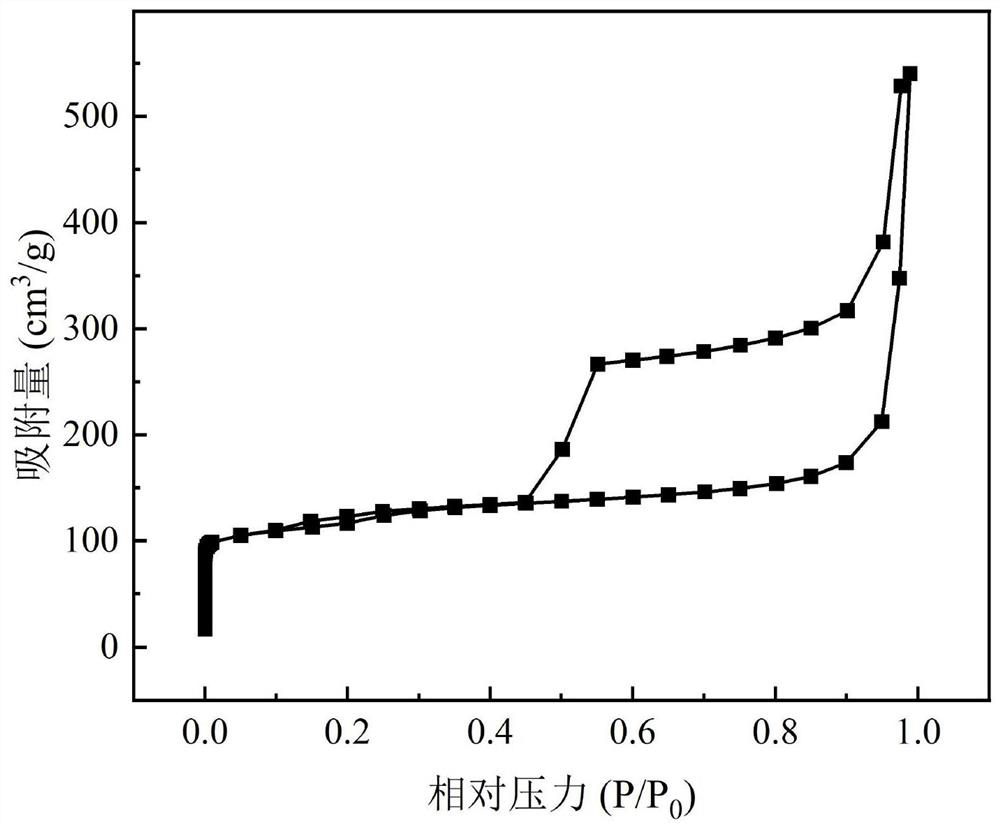

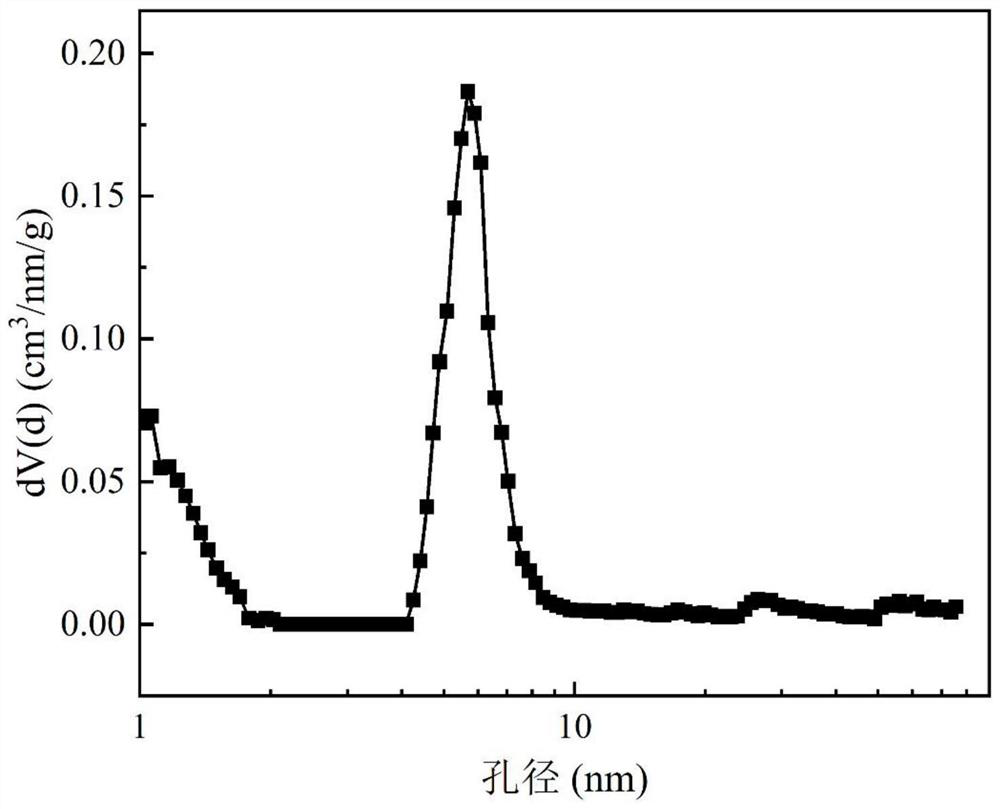

[0047] Embodiment 1: Preparation of hollow ZSM-5 molecular sieve catalyst, the steps are as follows:

[0048] 18.0g Tetraethyl Orthosilicate (TEOS), 27.8g Tetrapropylammonium Hydroxide (TPAOH), 39.2g Water (H 2 O) Mix evenly, and form a transparent solution after stirring at 35°C for 12 hours, and the molar ratio of the solution composition is 1SiO 2 :0.4TPAOH:35H 2 O: 4EtOH; transfer to an oven for crystallization at 170°C for 72h, collect the solid; dry at 120°C for 10h, and roast at 550°C for 8h; dissolve 3.0g of the roasted substance and 1.0g of aluminum nitrate in 60mL of 0.5mol / L In the ammonium hydroxide solution, SiO in the feed 2 :Al 2 o 3 =1:40, stirred at room temperature for 0.5h, stood in an oven at 170°C for 24h, centrifuged, dried at 120°C for 10h, and roasted at 550°C for 8h to obtain a hollow ZSM-5 molecular sieve;

[0049] Weigh 0.04g of tetraammineplatinum nitrate and dissolve it in 100mL of water, add ammonia water dropwise to adjust the pH of the solu...

Embodiment 2

[0058] Example 2: Hollow ZSM-5 molecular sieve loaded with metal Pt for catalytic hydrogenation of naphthalene

[0059] The hollow ZSM-5 molecular sieve-supported metal Pt catalyst obtained in Example 1 was reduced in advance by using a fixed bed reactor at 300-500° C. under a hydrogen atmosphere for 2-4 hours. Naphthalene hydrogenation reaction pressure 4MPa, temperature 160-180°C, hydrogen-oil ratio 300-500NmL / mL, weight hourly space velocity 21.6h -1 Under the condition, the hydrogenation reaction is carried out by using condensed ring aromatic hydrocarbon naphthalene as raw material and decahydronaphthalene as solvent.

[0060] Under different reaction conditions, the conversion rate of naphthalene and the distribution of hydrogenation products are shown in Table 2. As can be seen from Table 2, under the reaction conditions adopted, the selectivity of decahydronaphthalene is all greater than 96%; ).

[0061] Table 2 Conditions and results of naphthalene hydrogenation

...

Embodiment 3

[0063] Example 3: Hollow ZSM-5 molecular sieve supports metal Pt for catalyzing the hydrogenation reaction of acenaphthylene

[0064] The hollow ZSM-5 molecular sieve-supported metal Pt catalyst obtained in Example 1 was reduced in advance by using a fixed bed reactor at 300-500° C. under a hydrogen atmosphere for 2-4 hours. The hydrogenation reaction pressure of acenaphthylene is 4MPa, the temperature is 220-240°C, the hydrogen oil ratio is 300-500NmL / mL, and the weight hourly space velocity is 21.6-32.4h -1 Under the conditions, the hydrogenation reaction is carried out by using the condensed ring aromatic hydrocarbon acenaphthylene as the raw material and decahydronaphthalene as the solvent.

[0065] Under different reaction conditions, the conversion rate of acenaphthylene and the distribution of hydrogenation products are shown in Table 3. It can be seen that under the reaction conditions adopted, the selectivity of perhydroacenaphthene is greater than 99%; the density o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com