Method for preparing N-doped kudzuvine root-based mesoporous activated carbon and application thereof

A kudzu root-based mesoporous and nitrogen-doped technology, which is applied in the direction of hybrid capacitor electrodes, can solve the problems of unseen mesoporous activated carbon materials, and achieve the effects of easy industrial production, wide application prospects, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

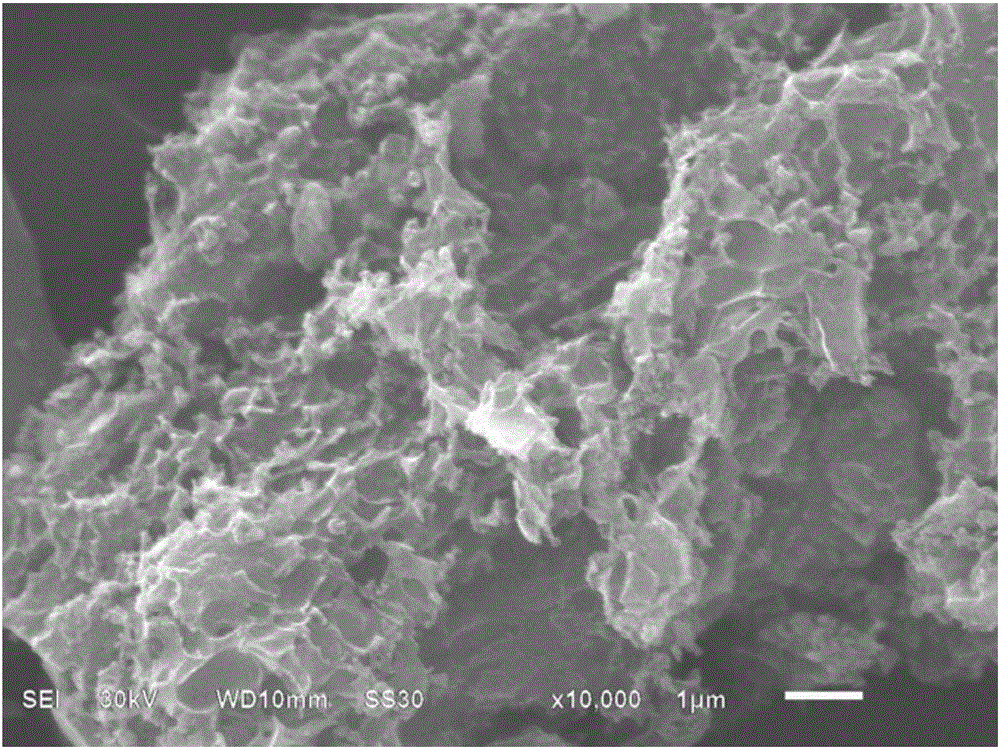

Embodiment 1

[0039] (1) Wash the kudzu root with water, cut it into discs with a thickness of 5mm, and dry it in a constant temperature drying oven at 100°C for 24 hours to obtain the kudzu root slices on a dry basis. Collect the undersieve to obtain kudzu root powder.

[0040] (2) 2.5g melamine was dissolved in 70mL distilled water earlier, then 5g kudzu root powder was added thereto, after stirring at room temperature for 30min, the mixture was transferred to a high-pressure hydrothermal reactor whose liner was polytetrafluoroethylene. The volume filling ratio is 0.4. After hydrothermal treatment at 180°C for 12 hours, it is cooled to room temperature. The hydrothermal product is subjected to solid-liquid separation and washed until neutral, and then the solid is dried at 100°C to constant weight to obtain nitrogen-doped Miscellaneous kudzu root hydrothermal charcoal.

[0041] (3) Potassium carbonate is made into the solution of 2mol / L concentration, then the nitrogen-doped kudzu root h...

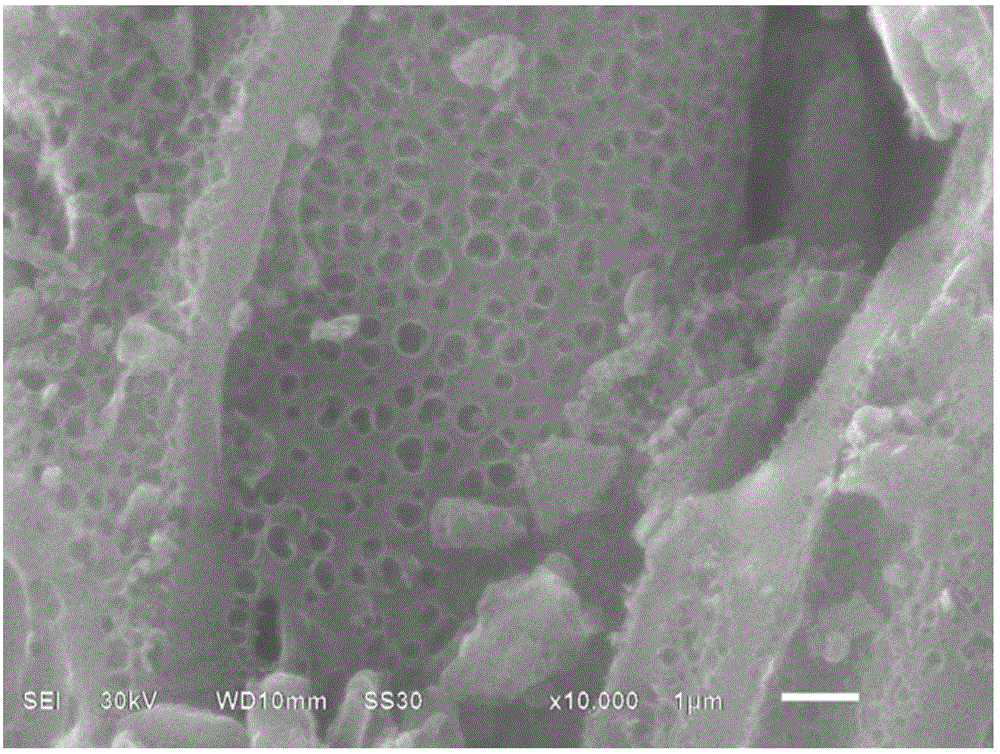

Embodiment 2

[0051] (1) Wash the kudzu root with water, cut it into discs with a thickness of 5mm, and dry it in a constant temperature drying oven at 100°C for 24 hours to obtain the kudzu root slices on a dry basis. Collect the undersieve to obtain kudzu root powder.

[0052] (2) Weigh 5g of ethylenediamine and place it in a 50ml crucible, cover it and put it into a muffle furnace, raise the temperature to 550°C at a rate of 2°C / min, then keep it warm for 4h, and take it out after the muffle furnace cools down to room temperature , after fully grinding, the powdered g-C 3 N 4 ,spare.

[0053] (3) Sodium hydroxide is made into a solution with a concentration of 1mol / L, and then the pueraria root powder obtained in step (1) is added thereto in a mass ratio of 1:1 with sodium hydroxide, and distilled water is added to control the liquid / solid mass ratio 10, stirred at room temperature for 12 hours, then dried and ground at 100°C to obtain a homogeneous mixture containing the activator. ...

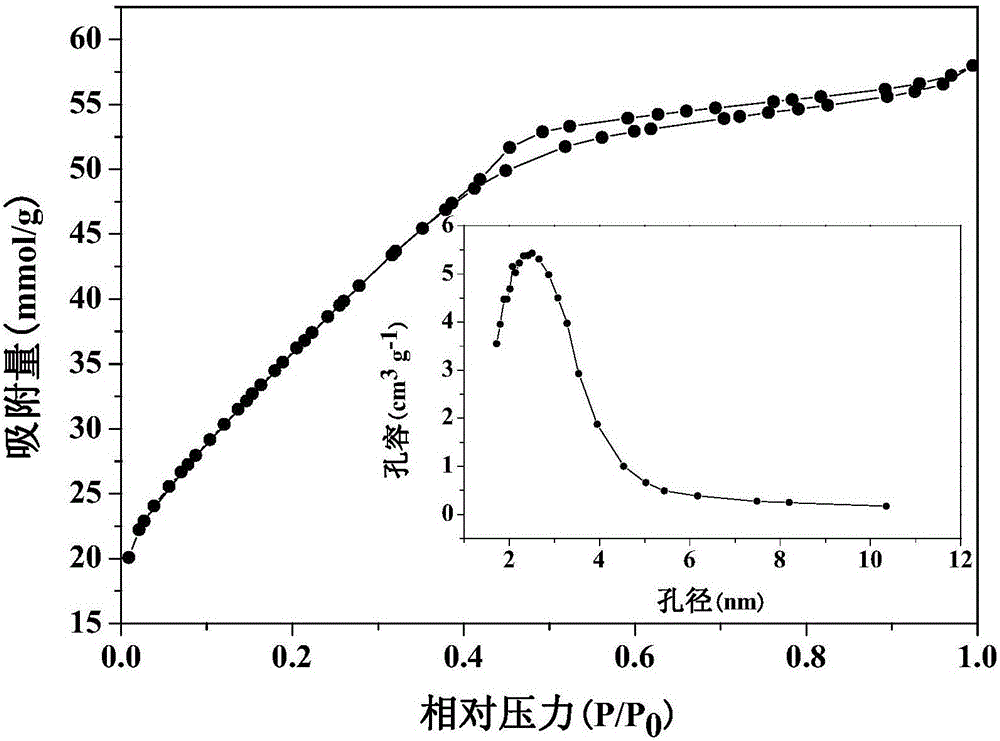

Embodiment 3

[0062] (1) Wash the kudzu root with water, cut it into discs with a thickness of 5mm, and dry it in a constant temperature drying oven at 100°C for 24 hours to obtain the kudzu root slices on a dry basis. Collect the undersieve to obtain kudzu root powder.

[0063] (2) Add distilled water to the pueraria root powder obtained in step (1) and stir for 1 h to form a mixture with a liquid / solid mass ratio of 5, and transfer this mixture to a high-pressure hydrothermal reactor whose inner liner is polytetrafluoroethylene , the volume filling ratio is 0.6, after hydrothermal treatment at 180°C for 12h, it is cooled to room temperature, the hydrothermal product is subjected to solid-liquid separation and washed to neutrality, and then the solid is dried at 100°C to constant weight, that is, Pueraria root hydrothermal charcoal.

[0064] (3) Potassium phosphate is made into the solution of 3mol / L concentration earlier, then gained kudzu root base hydrothermal charcoal, unotropine, pot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com