Method for preparing different types of nitrogen-doped graphene with low-temperature plasma

A technology of nitrogen-doped graphene and low-temperature plasma, which is applied in the field of electrode materials, can solve the problem that the synthesis process cannot control the type of nitrogen doping, and achieve the effects of easy control of the reaction process, improvement of efficiency, and avoidance of the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

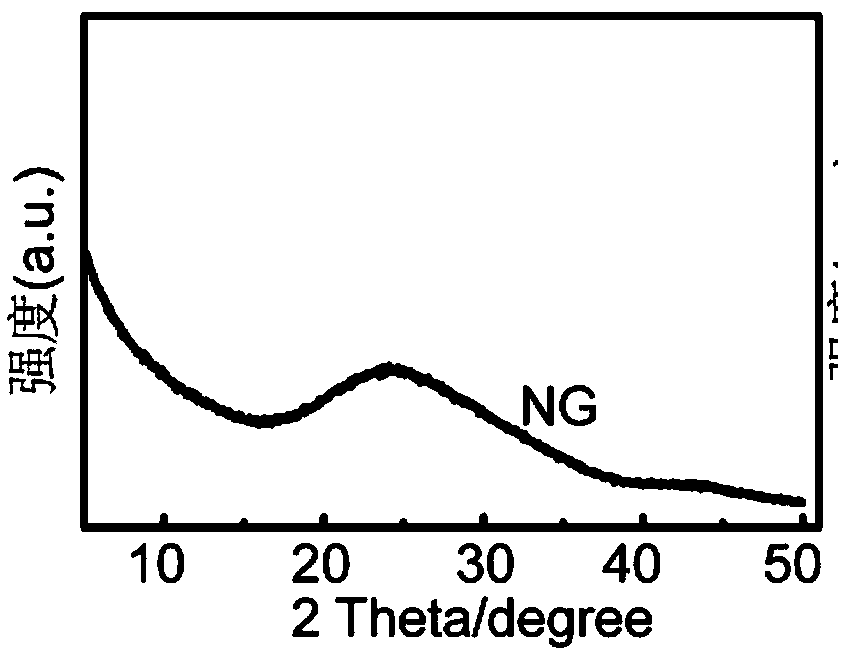

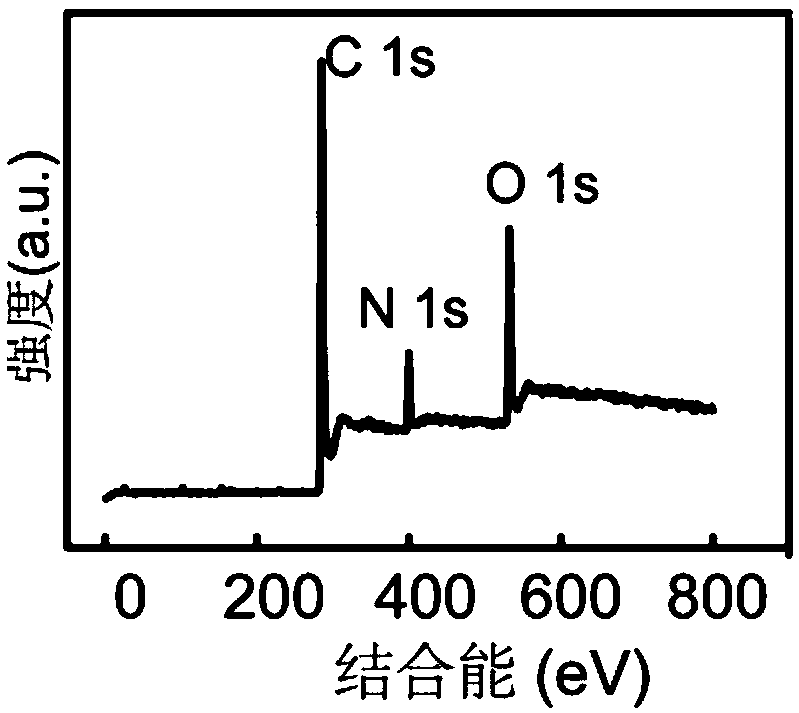

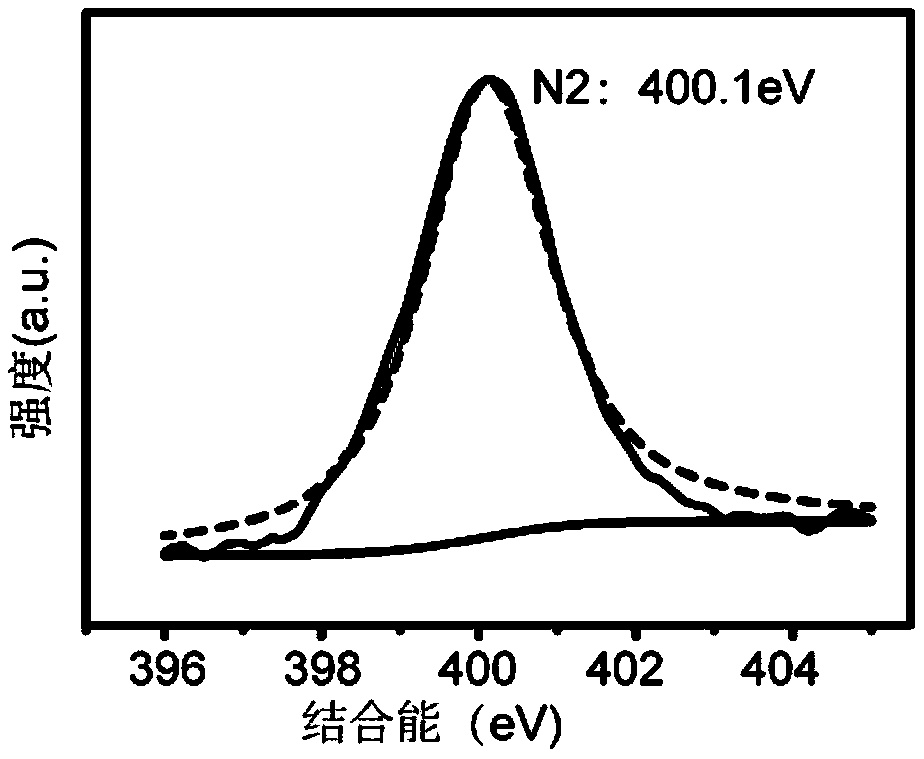

Embodiment 1

[0026] Such as Figure 6 Shown, a kind of method for preparing different types of nitrogen-doped graphene by low-temperature plasma, the method that comprises include: prepare graphene oxide with Hummers method, prepare the graphene oxide solution that concentration is 0.5mg / ml again, nitrogen-containing compound Add it into the graphene oxide solution to obtain a mixed solution, and the mass ratio of the nitrogen-containing compound to the graphene oxide solution is 1:1. The nitrogen-containing compound is a mixture of urea and pyridine with a mass ratio of 10:1. Then the mixed solution was ultrasonically dispersed for 15 minutes to obtain a dispersion of nitrogen-containing compound and graphene oxide. Then, the dispersion liquid was subjected to centrifugation at a rotational speed of 5000 rbm for 5 minutes to obtain a precipitated compound. The precipitated compound was freeze-dried in an environment at a temperature of -40° C. to obtain powders of the nitrogen-containin...

Embodiment 2

[0028] Such as Figure 6 Shown, a kind of method that low-temperature plasma prepares different types of nitrogen-doped graphenes, the method that comprises are: prepare graphene oxide with Hummers method, prepare the graphene oxide solution 10ml that concentration is 30mg / ml again, nitrogen-containing compound Add it into the graphene oxide solution to obtain a mixed solution, and the mass ratio of the nitrogen-containing compound to the graphene oxide is 1:5. Wherein the nitrogen-containing compound is a mixture of ammonia water and pyridine, and its mass ratio is 1:6. Then, the mixed solution was ultrasonically dispersed for 35 minutes to obtain a dispersion solution of nitrogen-containing compound and graphene oxide. Then, the dispersion liquid was subjected to centrifugation at a rotational speed of 8000rbm for 20min to obtain a precipitated compound. The precipitated compound was freeze-dried in an environment at a temperature of -20° C. to obtain powders of the nitrog...

Embodiment 3

[0030] Such as Figure 6 As shown, a method for preparing different types of nitrogen-doped graphene by low-temperature plasma includes the following methods: preparing graphene oxide by the Hummers method, then preparing a graphene oxide solution with a concentration of 50 mg / ml, and adding nitrogen-containing compounds into the graphene oxide solution to obtain a mixed solution, and the mass ratio of the nitrogen-containing compound to the graphene oxide is 1:10. Wherein the nitrogen-containing compound is a mixture of ammonia water and pyridine, and its mass ratio is 1:6. Then, the mixed solution was ultrasonically dispersed for 60 minutes to obtain a dispersion solution of nitrogen-containing compound and graphene oxide. Then, the dispersion liquid was subjected to centrifugation at a rotational speed of 12000rbm for 30min to obtain a precipitated compound. The precipitated compound was freeze-dried in an environment at a temperature of -40° C. to obtain powders of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com