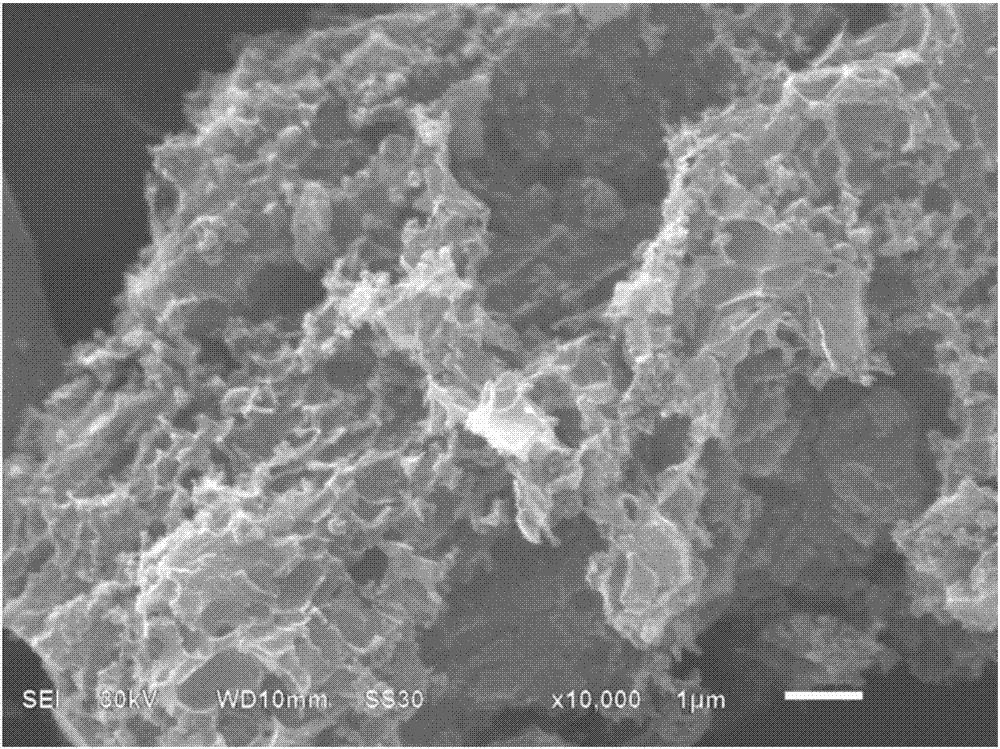

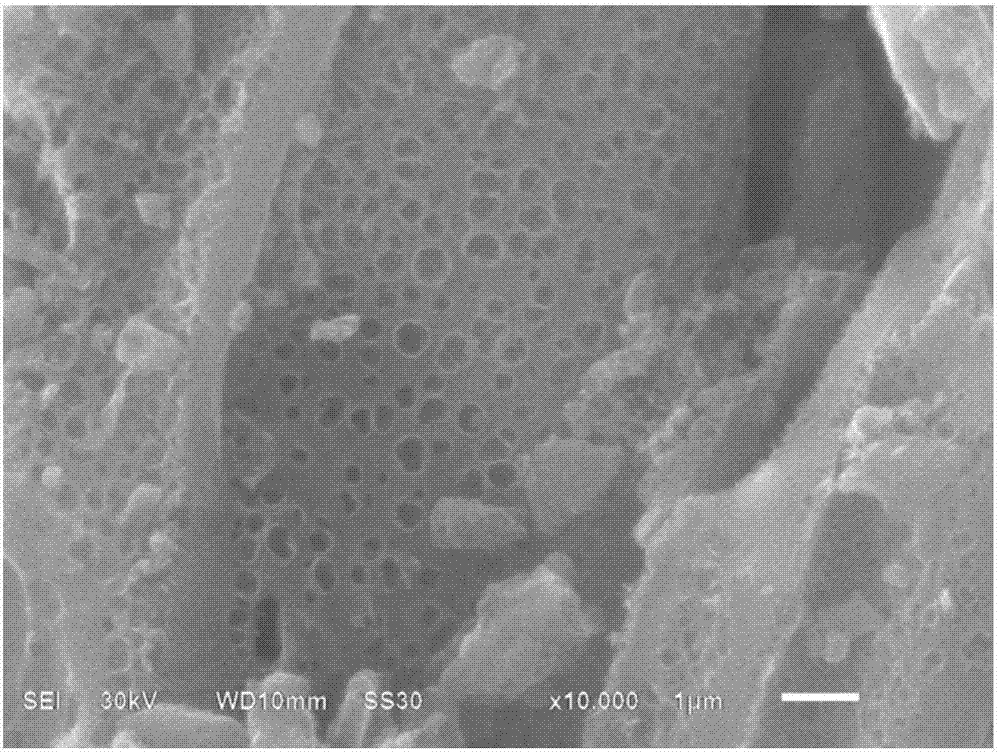

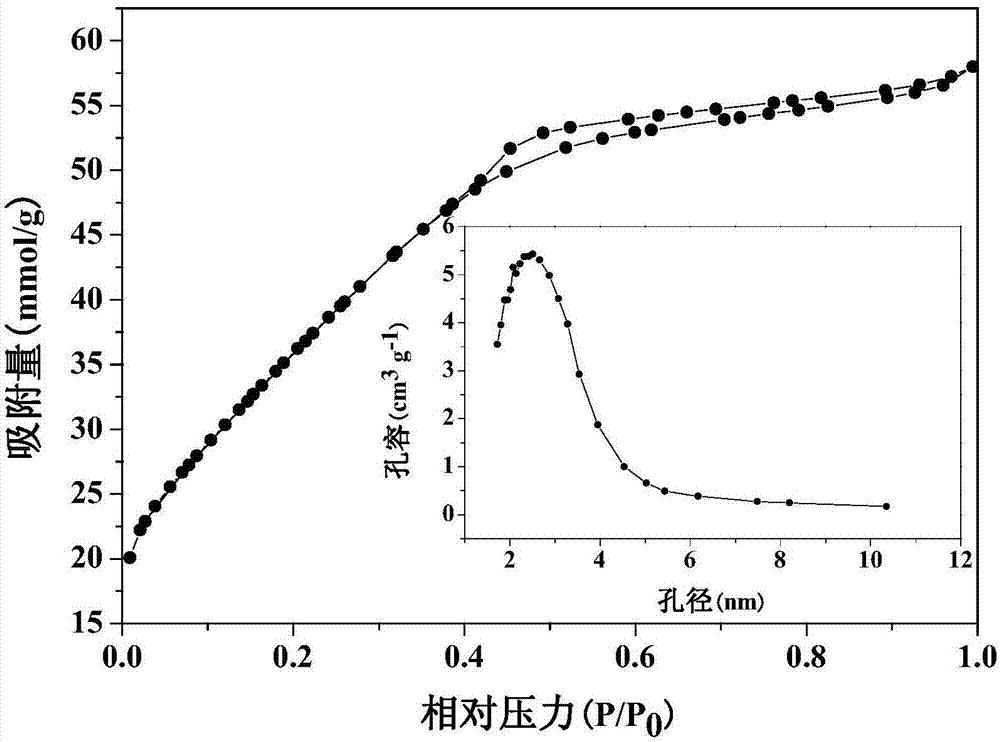

A kind of preparation method and application of nitrogen-doped kudzu root mesoporous activated carbon

A kudzu root-based mesoporous and nitrogen-doped technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of unseen mesoporous activated carbon materials, and achieve easy industrial production, simple preparation process, Effect of High Mesopore Volume Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Wash the kudzu root with water, cut it into discs with a thickness of 5mm, and dry it in a constant temperature drying oven at 100°C for 24 hours to obtain the kudzu root slices on a dry basis. Collect the undersieve to obtain kudzu root powder.

[0040] (2) 2.5g melamine was dissolved in 70mL distilled water earlier, then 5g kudzu root powder was added thereto, after stirring at room temperature for 30min, the mixture was transferred to a high-pressure hydrothermal reactor whose liner was polytetrafluoroethylene. The volume filling ratio is 0.4. After hydrothermal treatment at 180°C for 12 hours, it is cooled to room temperature. The hydrothermal product is subjected to solid-liquid separation and washed until neutral, and then the solid is dried at 100°C to constant weight to obtain nitrogen-doped Miscellaneous kudzu root hydrothermal charcoal.

[0041] (3) Potassium carbonate is made into the solution of 2mol / L concentration, then the nitrogen-doped kudzu root h...

Embodiment 2

[0051] (1) Wash the kudzu root with water, cut it into discs with a thickness of 5mm, and dry it in a constant temperature drying oven at 100°C for 24 hours to obtain the kudzu root slices on a dry basis. Collect the undersieve to obtain kudzu root powder.

[0052] (2) Weigh 5g of ethylenediamine and place it in a 50ml crucible, cover it and put it into a muffle furnace, raise the temperature to 550°C at a rate of 2°C / min, then keep it warm for 4h, and take it out after the muffle furnace cools down to room temperature , after fully grinding, the powdered g-C 3 N 4 ,spare.

[0053] (3) Sodium hydroxide is made into a solution with a concentration of 1mol / L, and then the pueraria root powder obtained in step (1) is added thereto in a mass ratio of 1:1 with sodium hydroxide, and distilled water is added to control the liquid / solid mass ratio 10, stirred at room temperature for 12 hours, then dried and ground at 100°C to obtain a homogeneous mixture containing the activator. ...

Embodiment 3

[0062] (1) Wash the kudzu root with water, cut it into discs with a thickness of 5mm, and dry it in a constant temperature drying oven at 100°C for 24 hours to obtain the kudzu root slices on a dry basis. Collect the undersieve to obtain kudzu root powder.

[0063] (2) Add distilled water to the pueraria root powder obtained in step (1) and stir for 1 h to form a mixture with a liquid / solid mass ratio of 5, and transfer this mixture to a high-pressure hydrothermal reactor whose inner liner is polytetrafluoroethylene , the volume filling ratio is 0.6, after hydrothermal treatment at 180°C for 12h, it is cooled to room temperature, the hydrothermal product is subjected to solid-liquid separation and washed to neutrality, and then the solid is dried at 100°C to constant weight, that is, Pueraria root hydrothermal charcoal.

[0064] (3) Potassium phosphate is made into the solution of 3mol / L concentration earlier, then gained kudzu root base hydrothermal charcoal, unotropine, pot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com