Method for preparing hierarchical pore Y zeolite through oxalic acid-ammonium hydroxide cotreatment

A molecular sieve and multi-stage pore technology, applied in the field of molecular sieves, can solve the problems of small external surface area and mesopore volume of multi-stage pore Y molecular sieves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the method for preparing hierarchically porous Y molecular sieves by oxalic acid-ammonia co-treatment

[0022] Acid treatment of oxalic acid solution: Weigh 6g of NaY molecular sieve and prepare 100ml of H with a concentration of 0.12mol / L 2 C 2 o 4 The solution is ready for use. Add 15ml of H for every 1g of sample 2 C 2 o 4 The ratio of the solution, the above sample and the amount taken out of the H 2 C 2 o 4 The solution was mixed evenly in the flask, placed in an oil bath with a constant temperature of 363K, and stirred for 60 minutes. The mixed solution after the above oil bath treatment was filtered under reduced pressure until the filtrate was nearly neutral, and then put into a 337K oven to dry overnight. After H 2 C 2 o 4 Solution-treated samples were recorded as AT.

[0023] NH 3 ·H 2 Alkaline treatment of O solution: add 20ml of NH per 1g of sample 3 ·H 2 The ratio of O solution to the above sample and the amount of NH 3 ·H 2...

Embodiment 2

[0024] Embodiment 2: the method for preparing hierarchically porous Y molecular sieves by oxalic acid-ammonia co-treatment

[0025] Acid treatment of oxalic acid solution: Weigh 6g of NaY molecular sieve and prepare 100ml of H with a concentration of 0.12mol / L 2 C 2 o 4 The solution is ready for use. Add 15ml of H for every 1g of sample 2 C 2 o 4 The ratio of the solution, the above sample and the amount taken out of the H 2 C 2 o 4 The solution was mixed evenly in the flask, placed in an oil bath with a constant temperature of 363K, and stirred for 60 minutes. The mixed solution after the above oil bath treatment was filtered under reduced pressure until the filtrate was nearly neutral, and then put into a 337K oven to dry overnight. After H 2 C 2 o 4 Solution-treated samples were recorded as AT.

[0026] NH 3 ·H 2 Alkaline treatment of O solution: add 20ml of NH per 1g of sample 3 ·H 2 The ratio of O solution to the above sample and the amount of NH 3 ·H 2...

Embodiment 3

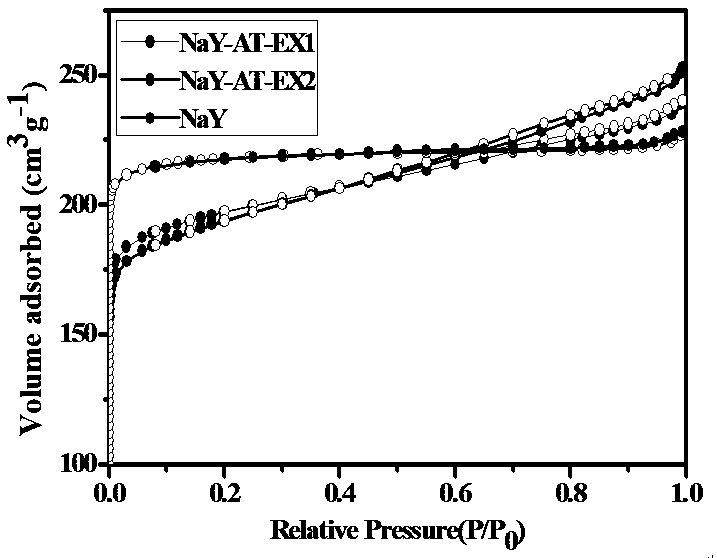

[0028] The method of oxalic acid-ammonia co-treatment was used to prepare hierarchically porous NaY molecular sieves. The concentration of oxalic acid was selected as 0.12mol / L and the treatment temperature was 90°C. The reaction time of ammonia water was adjusted to see the mesopore formation under different reaction times. The specific experimental conditions are shown in Table 1.

[0029] Table 1. Labeling and processing conditions of samples

[0030] Sample model Reagent pH T(K) t(h) AT h 2 C 2 o 4

1 363 1 E1 NH 3 ·H 2 o

11 328 4 E2 NH 3 ·H 2 o

11 328 8

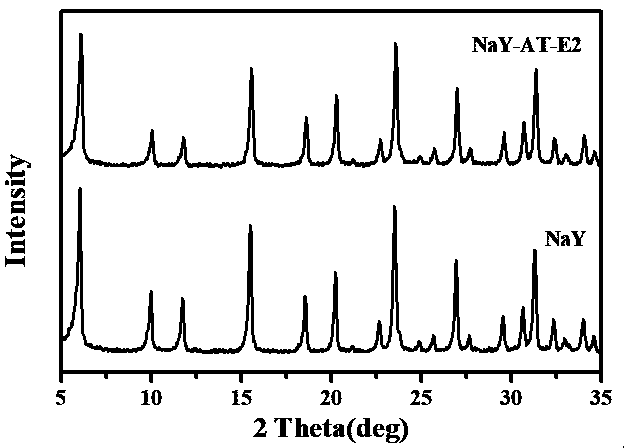

[0031] (1) XRD of molecular sieve

[0032] figure 1 The XRD patterns of NaY and NaY-AT-E2 molecular sieves are given. By observing the crystal structure of Y molecular sieve before and after modification with oxalic acid-ammonia water, it can be seen that: NaY-AT-E2 molecular sieve is still the structure of Y-type molecular sieve, and no other miscel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com