One-step molding method of titanium silicalite molecular sieve

A technology of titanium silicon molecular sieve and tetraethyl orthosilicate, which is applied in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of separation and recovery of difficult products, improve the effect and strengthen the adhesion. The effect of force, high wear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

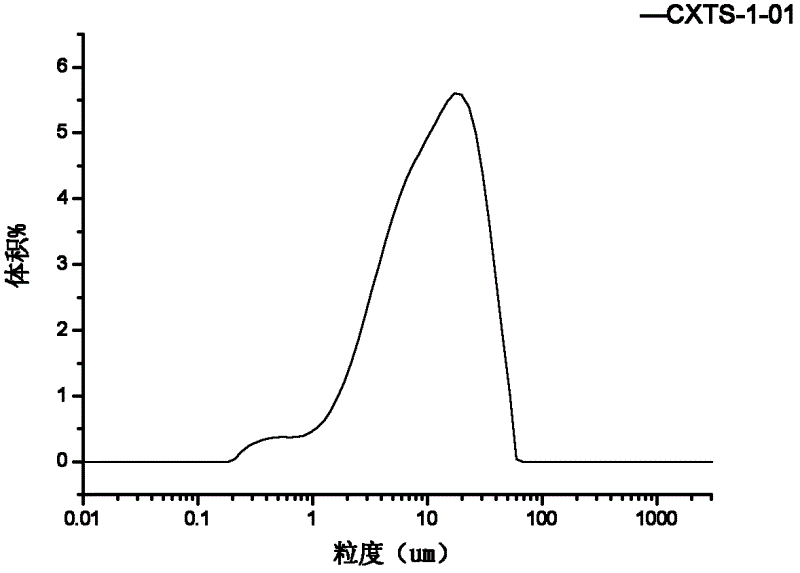

[0039] Embodiment 1 (preparation of titanium-silicon molecular sieve crystallization solution and titanium-silicon molecular sieve former powder)

[0040] Molar ratio 1TEOS: 0.21TPAOH: 0.041TBOT: 41H 2 O: 0.98IPA Weigh the raw materials, first weigh 145.16g TEOS and 160.44g 19.2% TPAOH aqueous solution into a three-necked flask, add 200.15g water, and fully stir the mixed solution in a water bath at 60°C for 1 hour for hydrolysis. Weigh again 40.90g IPA and 9.65g TBOT, add them into a three-necked flask through a dropping funnel, raise the temperature of the water bath to 80°C, remove isopropanol under stirring conditions, and replenish 50.08g of water every 2 hours, for a total of 150.24g of water. Dealcoholized for 7 hours and concentrated to obtain a gel, which was transferred into a crystallization kettle, crystallized at 170° C. for 72 hours, and then rapidly cooled to obtain a crystallization solution of a titanium-silicon molecular sieve precursor.

[0041] A small amo...

Embodiment 2

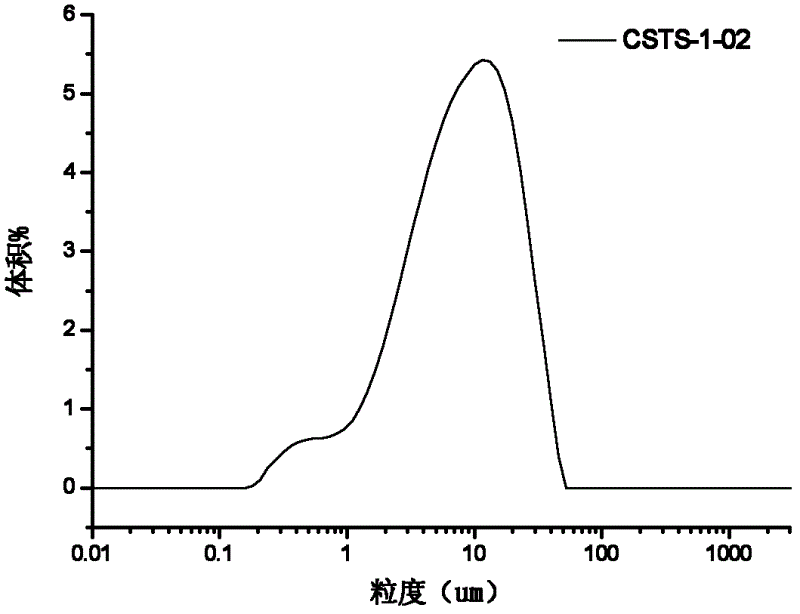

[0042] Embodiment 2 (preparation of one-shot molding catalyst)

[0043] Take an appropriate amount of the crystallization solution of the titanium-silicon-containing molecular sieve precursor obtained in Example 1, and add kaolin, silica sol, nitric acid, squash powder, polyethylene glycol and water respectively. The content of each component is: 127.51g of crystallization solution, 3.15g of kaolin, 2.50g of silica gel, 0.22g of nitric acid, 0.22g of citric acid, 0.21g of squash powder, 0.23g of polyethylene glycol, and 19.71g of water. Prepare slurry for spray drying by beating, control its solid content to 10%, spray molding under the conditions of inlet temperature 240°C, outlet temperature 140°C, feed rate 10ml / min, atomization frequency 150Hz.

[0044] The shaped particles were calcined under the condition of programmed temperature, the heating rate was 5°C / min, and the calcining was carried out at 130°C for 30 minutes in an air atmosphere, at 330°C for 30 minutes, at 500...

Embodiment 3

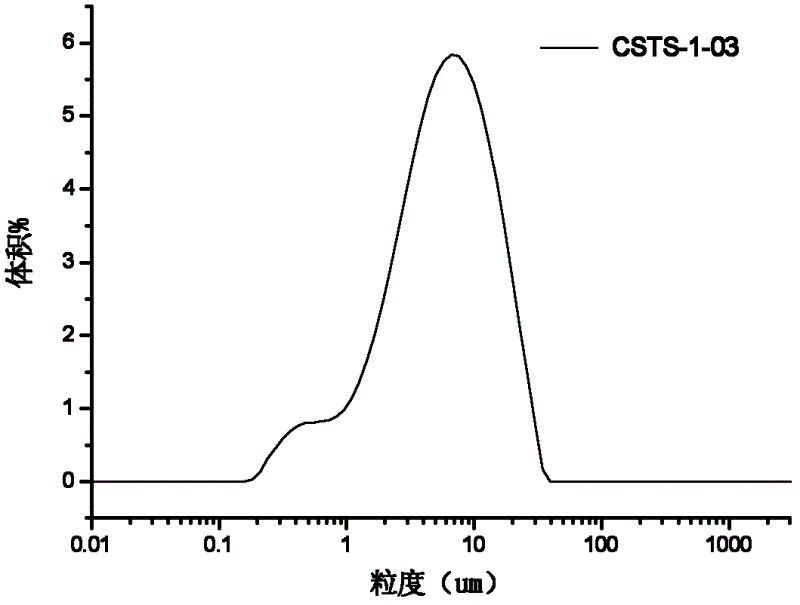

[0046] Embodiment 3 (preparation of one-shot molding catalyst)

[0047] Take an appropriate amount of the crystallization solution of the titanium-silicon-containing molecular sieve precursor obtained in Example 1, and add kaolin, silica sol, nitric acid, squash powder, and polyethylene glycol respectively. The content of each component is 125.94 g of crystallization liquid, 3.12 g of kaolin, 2.67 g of silica gel, 0.6 g of nitric acid, 0.27 g of citric acid, 0.29 g of scallop powder, and 0.33 g of polyethylene glycol. Under vacuum conditions, 51.84 g of water is removed first, the solid content of the solution is controlled to be 20%, and then beating is performed to prepare a slurry for spray drying. The slurry was sprayed and formed under the conditions of an inlet temperature of 250°C, an outlet temperature of 150°C, a feed rate of 30ml / min, and an atomization frequency of 150Hz.

[0048] The shaped particles were calcined under programmed temperature control conditions, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com