Three-dimensional dendritic structure TiO2 array preparation method

A three-dimensional dendritic and array technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of unfavorable photogenerated charge transport, poor incident light capture ability, and insufficient contact, etc., to achieve high light absorption and photogenerated charge transmission efficiency , low cost, and the effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

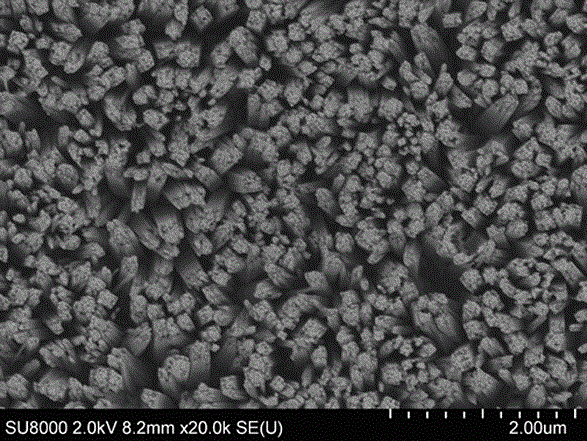

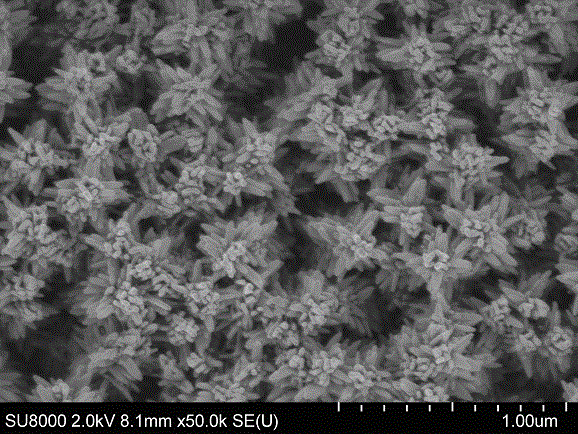

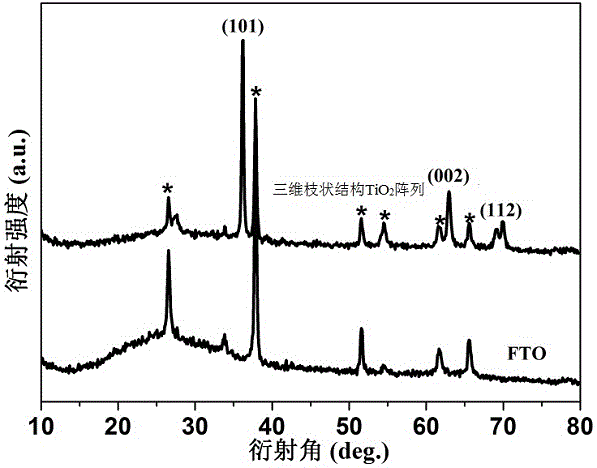

[0017] (1) Mix 24mL deionized water and 24mL concentrated hydrochloric acid with a mass concentration of 37% evenly, then add 0.8mL tetrabutyl titanate, stir until the solution is clear to obtain a precursor solution, and transfer the obtained precursor solution to a hydrothermal Put the clean conductive glass in the reaction kettle, then hydrothermally react at 150°C for 10h, cool down to room temperature naturally, take out the sample, rinse it and dry it, then put it in a muffle furnace and calcinate at 450°C for 30min to improve the crystallization Tetragonal TiO 2 nanorod arrays;

[0018] (2) Mix 10 mL of deionized water and 100 μL of concentrated hydrochloric acid with a mass concentration of 37% and add 50 μL of titanium trichloride. After mixing evenly, transfer to a hydrothermal reaction kettle. Put the pre-synthesized tetragonal TiO 2 The nanorod arrays were placed in a hydrothermal reactor at 80°C for 15 minutes, cooled naturally to room temperature, the samples we...

Embodiment 2

[0021] (1) Mix 24mL deionized water and 24mL concentrated hydrochloric acid with a mass concentration of 37% evenly, then add 0.8mL tetrabutyl titanate, stir until the solution is clear to obtain a precursor solution, and transfer the obtained precursor solution to a hydrothermal Put clean conductive glass in the reaction kettle, then react with water at 150°C for 20h, cool down to room temperature naturally, take out the sample, rinse it and dry it, then put it in a muffle furnace and calcinate at 450°C for 30min to improve crystallization Tetragonal TiO 2 nanorod arrays;

[0022] (2) Mix 10mL deionized water and 100μL concentrated hydrochloric acid with a mass concentration of 37% evenly, then add 100μL titanium trichloride, mix evenly, transfer to a hydrothermal reaction kettle, and put the pre-synthesized tetragonal TiO 2 The nanorod arrays were placed in a hydrothermal reactor at 80°C for 60 minutes, cooled naturally to room temperature, the samples were taken out, rinse...

Embodiment 3

[0024] (1) Mix 24mL deionized water and 24mL concentrated hydrochloric acid with a mass concentration of 37% evenly, then add 0.8mL tetrabutyl titanate, stir until the solution is clear to obtain a precursor solution, and transfer the obtained precursor solution to a hydrothermal Put clean conductive glass in the reaction kettle, then react with water at 150°C for 15 hours, cool down to room temperature naturally, take out the sample, rinse it and dry it, then put it in a muffle furnace and calcinate at 450°C for 30 minutes to improve crystallization Tetragonal TiO 2 nanorod arrays;

[0025] (2) Mix 10 mL of deionized water and 100 μL of concentrated hydrochloric acid with a mass concentration of 37% evenly, then add 75 μL of titanium trichloride, mix evenly, transfer to a hydrothermal reaction kettle, and put the pre-synthesized tetragonal TiO 2 The nanorod arrays were placed in a hydrothermal reactor at 120°C for 60 minutes, cooled naturally to room temperature, the samples...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com