Method for preparing nano copper powder in micromolecular viscous medium

A technology of nano-copper powder and small molecules, applied in the field of nano-metal materials, to achieve the effect of reducing migration rate, preventing foam and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

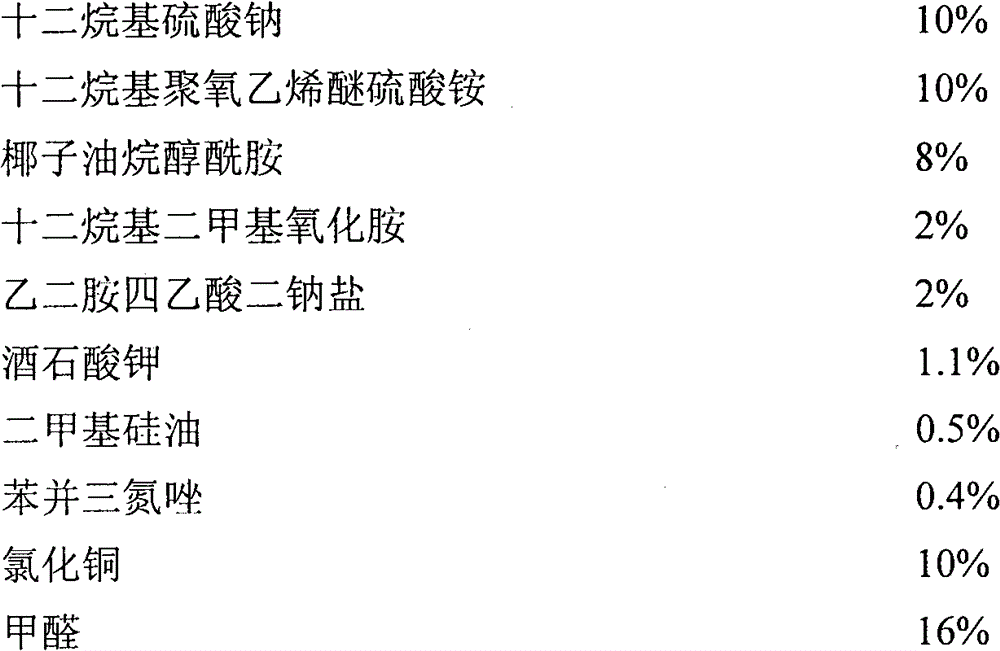

Embodiment 1

[0026]

[0027]

[0028] Preparation process: According to the above mass percentage, sodium lauryl sulfate, ammonium lauryl polyoxyethylene ether sulfate, coconut oil alkanolamide, lauryl dimethyl amine oxide, disodium edetate Salt, potassium tartrate, simethicone, benzotriazole and deionized water are mixed and stirred evenly to prepare a small molecule viscous medium, and copper chloride is added to stir evenly, and formaldehyde is added to stir until the reaction is complete. The mass ratio of the total amount of material to deionized water is 1:1. Add deionized water to dilute to reduce the viscosity. After press filtration, deionized water washing, acetone washing and vacuum drying, nano-copper powder can be obtained. After the press filtrate is concentrated recycle.

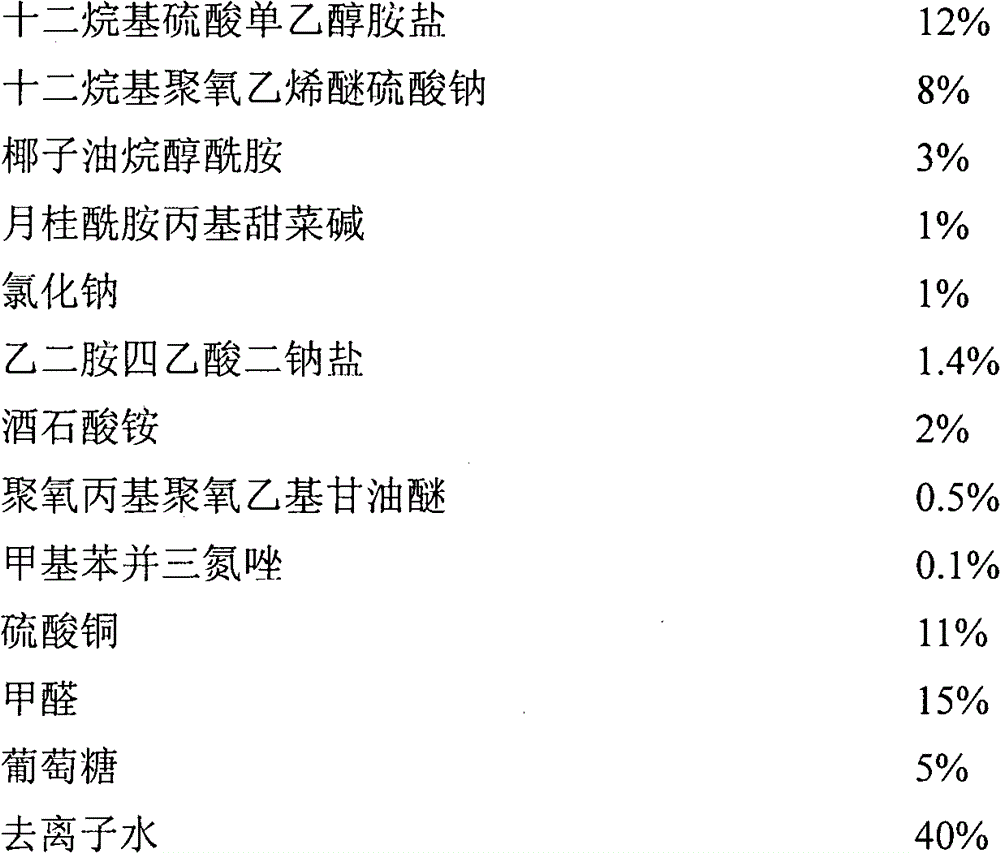

Embodiment 2

[0030]

[0031] Preparation process: According to the above mass percentage, lauryl sulfate monoethanolamine salt, sodium lauryl polyoxyethylene ether sulfate, coconut oil alkanolamide, lauryl amidopropyl betaine, sodium chloride, ethylenediaminetetra Disodium acetate, ammonium tartrate, polyoxypropyl polyoxyethyl glyceryl ether, tolyltriazole and deionized water are mixed and stirred evenly to prepare a small molecule viscous medium, and copper sulfate is added to stir evenly, and formaldehyde is added Stir with glucose until the reaction is complete, then add deionized water to dilute the viscosity according to the mass ratio of all the above-mentioned total materials to deionized water in a ratio of 1: 1.2, press filter, wash with deionized water, wash with acetone and The nano-copper powder is obtained by vacuum drying, and the filtrate is concentrated and recycled.

Embodiment 3

[0033]

[0034]

[0035] Preparation process: According to the above mass percentage, sodium cetyl sulfonate, sodium ammonium nonylphenol polyoxyethylene ether sulfate, triethanolamine lauryl polyoxyethylene ether sulfate, coconut oil alkanolamide, coconut oil amide Propyl betaine, lithium chloride, edetate disodium salt, sodium tartrate, polyoxypropyl polyoxyethyl glycerol ether, N-hydroxybenzotriazole and deionized water are mixed and stirred evenly to prepare Small molecule viscous medium, add copper chloride and stir evenly, add sodium hypophosphite and stir until the reaction is complete, then add deionized water to dilute according to the mass ratio of the total amount of all materials above to deionized water of 1:1.5 The viscosity is reduced, and the nano-copper powder is obtained through press filtration, deionized water washing, acetone washing and vacuum drying, and the press filtrate is concentrated and then recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com