Ultrathin metal shell lithium ion battery and preparation method thereof

A lithium-ion battery and ultra-thin metal technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve the problems of high impact of large-scale production and processing costs, inability to industrialize production, and inability to guarantee safety. Achieve the effect of improving the first charge-discharge efficiency and cycle life, reducing the migration distance, high volume energy density and gravimetric energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

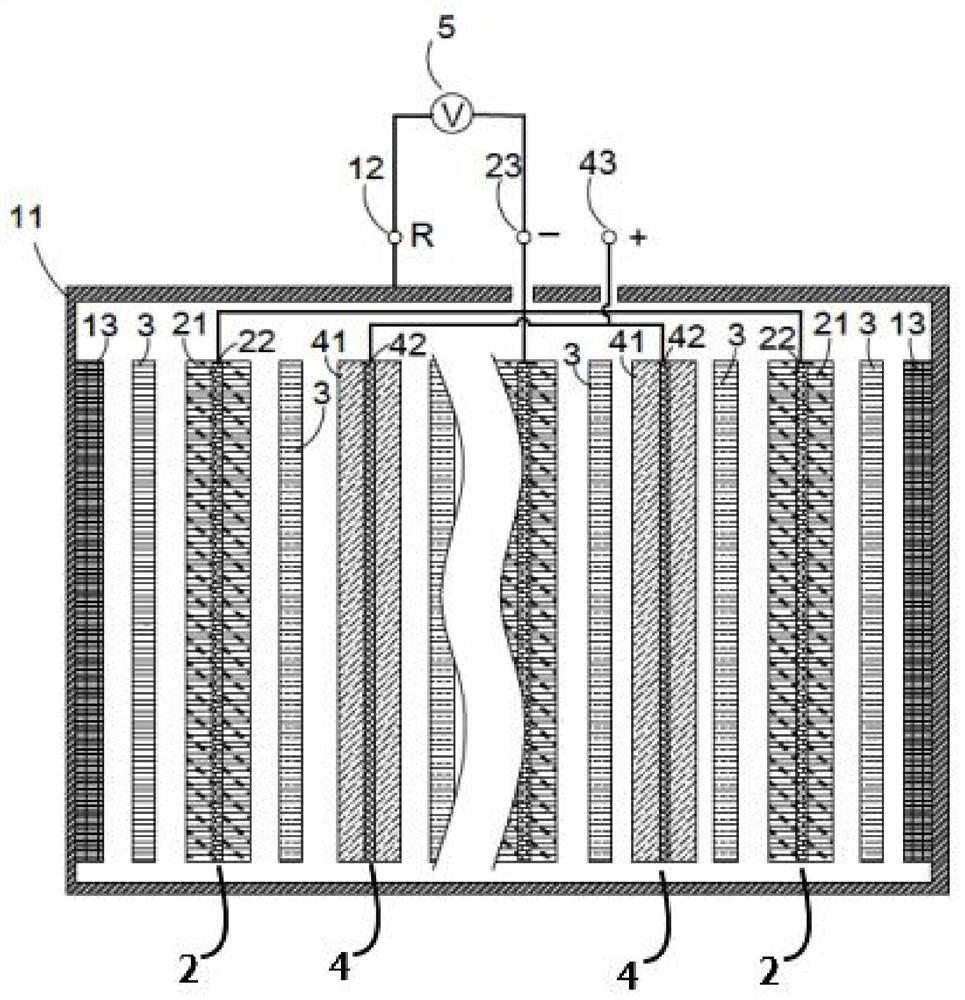

[0033] Such as figure 1 As shown, the present invention provides a lithium-ion battery with an ultra-thin metal case, comprising an ultra-thin metal case 11 and an internal cell, the internal cell is composed of a positive pole piece 4, a negative pole piece 2, a separator 3 and an electrolyte, and the positive pole The pole piece 4 includes a positive pole piece current collector 42 and a positive pole piece coating 41 coated on both sides of the positive pole piece current collector 42, and the negative pole piece 2 includes a negative pole piece current collector 22 and a coating coated on the negative pole piece. The negative electrode sheet coating 21 on both sides of the current collector 22, the inner wall of the ultra-thin metal shell 11 is embedded with a lithium metal layer 13 to form a lithium electrode, the outer surface of the ultra-thin metal shell 11 can reserve a metal exposed part or set a The pole column that shell is electrically connected forms lithium elec...

Embodiment 2

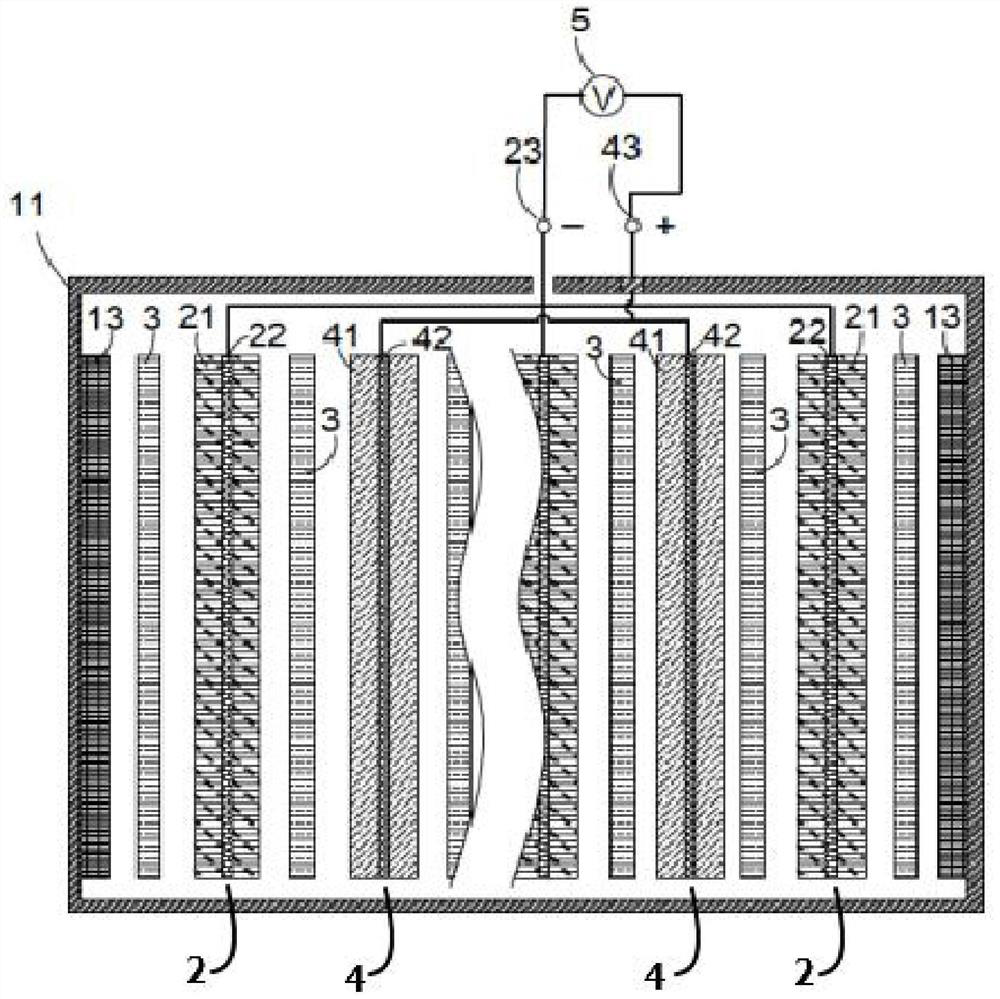

[0055] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the material of the ultra-thin metal shell is nickel-plated aluminum instead of the stainless steel plate in Embodiment 1, and the ultra-thin metal shell 11 is insulated from the negative electrode of the battery cell, and the ultra-thin metal shell 11 It is in contact with the positive lead wire 43 of the battery cell, and the lithium electrode terminal 12 is integrated with the positive lead wire 43 of the battery cell.

[0056] When performing pre-lithiation on the battery in this embodiment, first heat the cell to 40°C-50°C, and then connect the lithium electrode terminal 12 and the negative electrode lead 23 of the cell to the two terminals of the external power supply 5 for pre-lithiation. Charging, the voltage of the external power supply is 2.0V, and the pre-charged battery is placed at 40°C-50°C for 24-48 hours, and the lithium metal on the inner wall of the ultra-thin m...

Embodiment 3

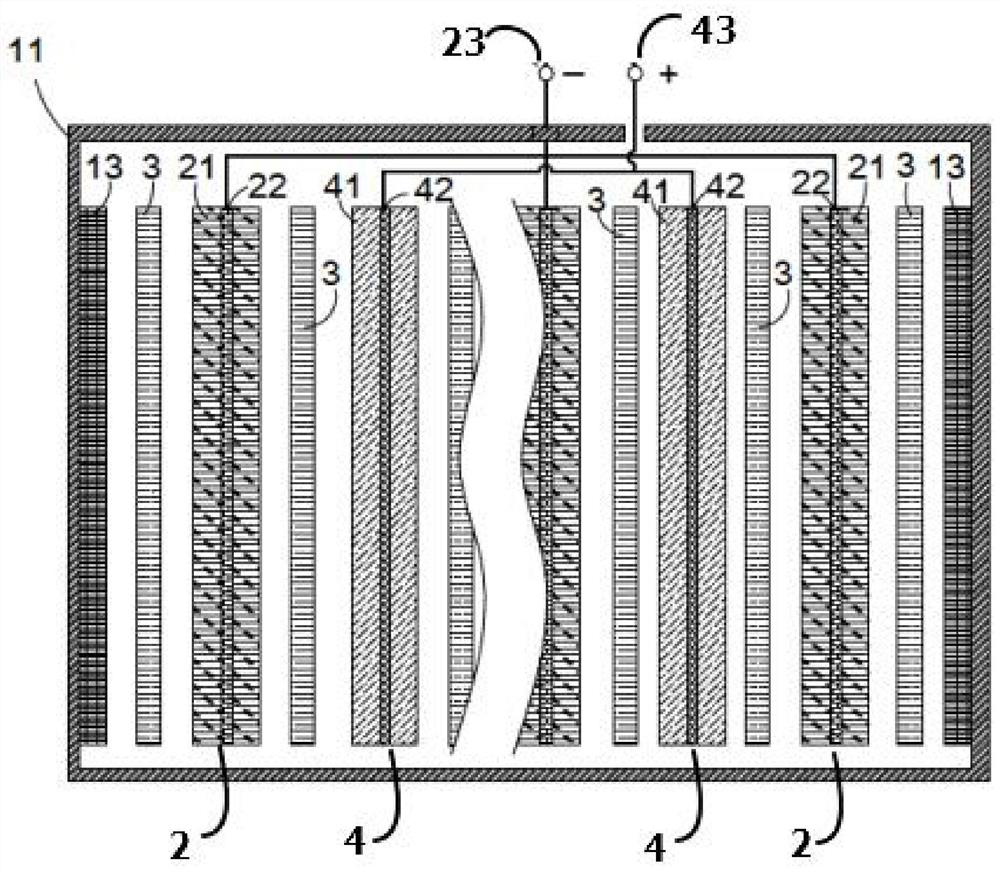

[0059] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the material of the ultra-thin metal shell is nickel-plated aluminum instead of the stainless steel plate in Embodiment 1, and the ultra-thin metal shell 11 is insulated from the positive electrode of the cell, and the ultra-thin metal shell 11 It is in contact with the negative electrode lead 23 of the battery cell, and the lithium electrode terminal 12 is integrated with the negative electrode lead 23 of the battery cell. The lithium metal on the inner wall of the ultra-thin metal shell spontaneously loses electrons under the action of the electrolyte and becomes lithium ions that migrate through the electrolyte. And pre-embedded in the negative pole piece 2.

[0060] In the battery of this embodiment, once the battery cell is filled with electrolyte, the lithium metal on the inner wall of the metal casing will spontaneously lose electrons and become lithium ions, which migrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com