Preparation method of three-dimensional graphene-titanium dioxide compound photocatalyst

A photocatalyst, titanium dioxide technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reducing the photocatalytic performance of titanium dioxide, agglomeration and overlapping of graphene nanosheets, low utilization rate, etc. , to achieve good photocatalytic performance, good electrical conductivity and catalytic performance, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

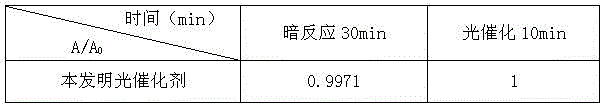

Image

Examples

Embodiment 1

[0025] In the mixture of 500mg graphite powder and 2.0g sodium nitrate, add 18ml of concentrated sulfuric acid with a mass concentration of 98%, and stir the reaction at a temperature lower than 5°C for 1h; then within 0.5h, slowly add 3.0g potassium permanganate powder, react for 1.5h at a temperature lower than 5°C; raise the temperature of the above reaction system to 35°C, keep it warm for 1h, add 40ml of deionized water to the reactor after the heat preservation, and then raise the temperature to 100°C , kept warm for 15min; then the reaction product was cooled to room temperature, diluted with 70 milliliters of deionized water, and then 10 milliliters of hydrogen peroxide solution with a mass concentration of 35% was added thereto; then the reaction product was filtered, and the obtained filter cake was first Wash three times with 400 ml of hydrochloric acid with a mass concentration of 5%, and then wash three times with deionized water, and finally use a dialysis bag to ...

Embodiment 2

[0031] The graphene oxide prepared in Example 1 was weighed to prepare a graphene oxide aqueous solution, and then a graphene-titanium dioxide composite with a three-dimensional structure was prepared. Weigh 60 mg of the obtained graphene oxide, disperse it in 30 ml of deionized water, ultrasonicate for 2 h, add 60 mg of titanium trichloride, stir well, then pipette 100 microliters of ammonia water with a mass concentration of 28% with a liquid gun, and ultrasonically After treating the reaction mixture, put it into a polytetrafluoroethylene-lined autoclave, and react at 180°C for 12 hours, and freeze-dry the obtained hydrogel product to prepare a three-dimensional graphene-titanium dioxide composite photocatalyst.

Embodiment 3

[0033] The graphene oxide prepared in Example 1 was weighed to prepare a graphene aqueous solution, and then a three-dimensional graphene-titanium dioxide composite was prepared. 120 mg of the obtained graphene oxide was dispersed in 60 ml of deionized water, and after ultrasonic treatment for 2.5 h, 120 mg of titanium trichloride was added, stirred evenly, and then 250 microliters of ammonia water with a mass concentration of 28% was pipetted with a pipette gun, and ultrasonically After treating the reaction mixture, put it into a polytetrafluoroethylene-lined autoclave, and react at 180°C for 12 hours, and freeze-dry the obtained hydrogel product to prepare a three-dimensional graphene-titanium dioxide composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com