Titanium sponge loading TiO2 photocatalyst and preparation method thereof

A photocatalyst, titanium sponge technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of expensive price and a large amount of organic solvents, and achieve low cost, good adsorption performance, light The effect of strong catalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

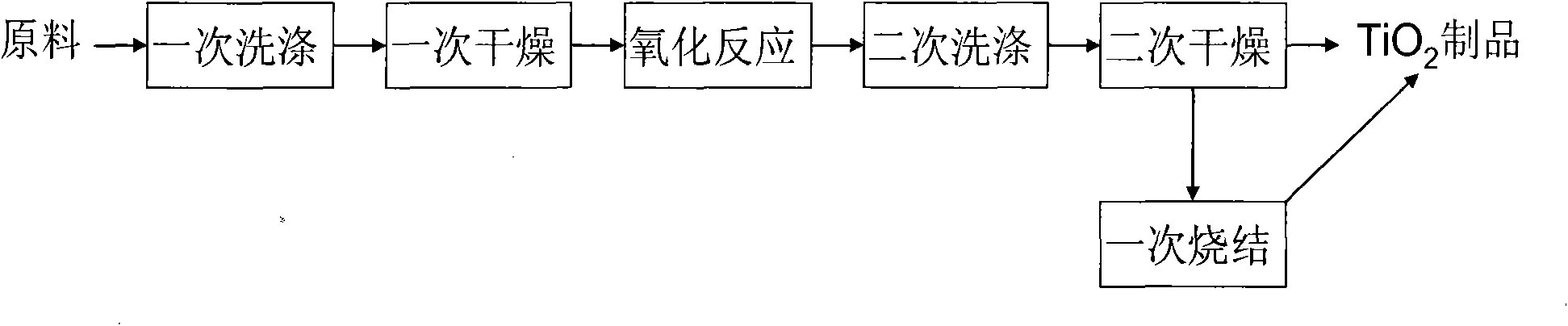

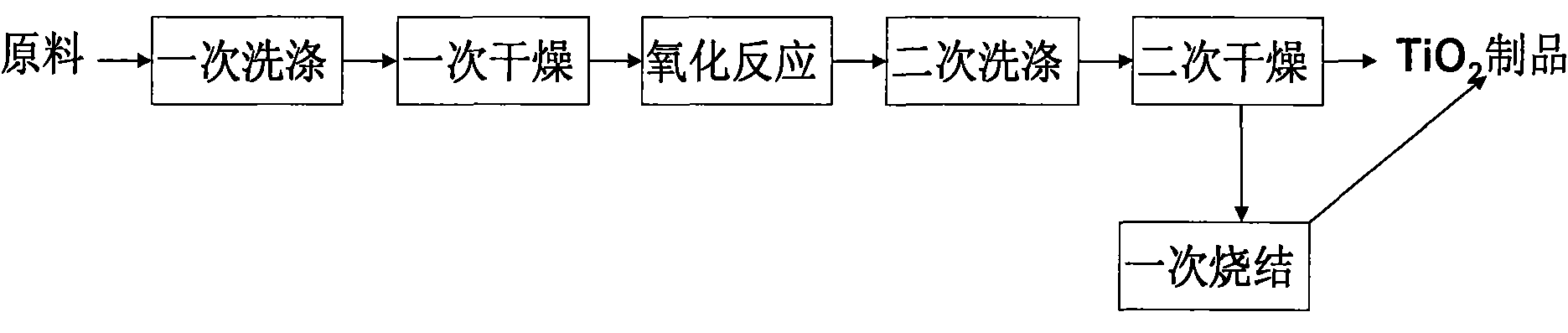

Image

Examples

Embodiment 1

[0032] First, add 3 kg of hydrochloric acid with a concentration of 1mol / L and 1 kg of titanium sponge with a purity of 96% into an ultrasonic washing machine for 1 hour. After filtering the acid solution, use organic solvent acetone and deionized water respectively Ultrasonic washing for 20 minutes and centrifugal drying, and then drying at 110 ° C for 1 hour, and then dry the titanium sponge with a concentration of 5 mol / L oxidant H 2 o 2 and 10 kg of the mixed solution of 1 mol / L HCl with a weight ratio of 40:3, heated and reacted at 75°C for 1.5 hours, then ultrasonically washed with deionized water until no turbidity appeared, and centrifuged to dry. Dry at 120°C for 0.5 hours; sinter the cleaned sponge titanium at 400°C for 2.5 hours to prepare sponge titanium-supported TiO 2 catalyst of light. The solvent and mother liquor used in the above steps are recovered and recycled.

[0033] The resulting product is titanium sponge loaded TiO 2 , the XRD test shows that the ...

Embodiment 2

[0035] First add 3 kg of hydrochloric acid with a concentration of 0.7 mol / L and 1 kg of titanium sponge with a purity of 96% into an ultrasonic washing machine for 1.5 hours. Ultrasonic washing with water for 15 minutes and centrifugal drying; after washing, the sponge titanium was dried at a temperature of 95-100°C for 1.5 hours; 2 S 2 o 3 And 3 kilograms of inorganic alkali NaOH aqueous solution, reaction temperature 150 ℃ lined polytetrafluoroethylene reactor reaction for 48 hours after the product was washed with deionized water and dried at 110 ℃ to get sponge titanium loaded TiO 2 . The solvent and mother liquor used in the above steps are recovered and recycled.

[0036] The resulting product is titanium sponge loaded TiO 2 , the XRD test shows that the titanium sponge loaded TiO 2 The crystal form is anatase crystal form; the degradation concentration is 15mg / L methylene blue solution under ultraviolet light irradiation, and the color is nearly completely faded i...

Embodiment 3

[0038] First, add 3 kg of hydrochloric acid with a concentration of 1.5 mol / L and 1 kg of titanium sponge with a purity of 96% into an ultrasonic washing machine for 1.5 hours. After filtering off the acid solution, use organic solvent methanol and deionized Ultrasonic washing with water for 25 minutes and centrifugal drying and drying at 105 ° C; 2 o 2 and 4 kg of inorganic alkali KOH aqueous solution, and reacted for 36 hours in an enamel reactor with a reaction temperature of 185 ° C; the reaction product was washed with deionized water and dried at 105 ° C to obtain a sponge titanium-loaded TiO 2 . The solvent and mother liquor used in the above steps are recovered and recycled.

[0039] The resulting product is titanium sponge loaded TiO 2 , the XRD test shows that the titanium sponge loaded TiO 2 The crystal form is anatase crystal form; the degradation concentration is 15mg / L methylene blue solution under ultraviolet light irradiation, and the color is almost comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com