Photocatalytic ceramsite as well as preparation method and application thereof

A technology of photocatalysis and ceramsite, which is applied in the field of photocatalytic materials, can solve the problems of no discovery and less co-doping, and achieve the effects of solving difficult recycling, improving photocatalytic activity, and broadening the wavelength range of photoresponse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

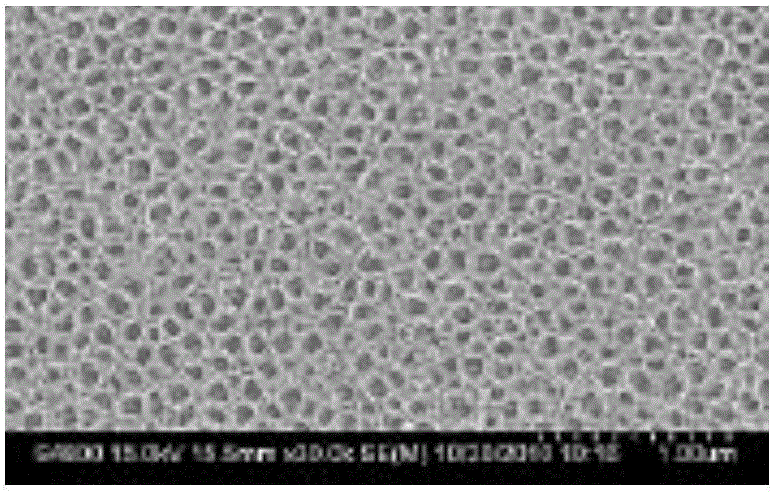

Image

Examples

preparation example Construction

[0047] (1) Preparation method of ceramsite carrier

[0048] (1) Get 40 parts of sludge, 40 parts of kaolin, 10 parts of sawdust, and 10 parts of calcium hydroxide, all in parts by weight. Fully mix and stir the above raw materials to make slurry, use a granulator to make the slurry into spherical particles with a diameter of 2mm, and dry it to form a billet;

[0049] (2) Place the mud body prepared in step (1) in a high-temperature sintering furnace, raise the temperature to 550°C at a heating rate of 80°C / h and keep it for 2 hours, and then continue to heat it up to 1000°C at a heating rate of 100°C / h After 3 hours, the heating was stopped, and the furnace temperature was lowered to room temperature at a rate of 150°C / h to obtain porous ceramsite for later use.

[0050] (2) Preparation method of ceramsite carrier

[0051] (1) Get 50 parts of sludge, 30 parts of bentonite, 10 parts of activated carbon, and 15 parts of calcium hydroxide, all in parts by weight. Fully mix and...

Embodiment 1

[0068] A method for preparing photocatalytic ceramsite, doping TiO with Sm in a ratio of 1:10 2 Nano-powder and porous ceramsite are placed in NaOH aqueous solution with a pH of 10. The amount of NaOH aqueous solution should be enough to cover the porous ceramsite; magnetic stirring for 10 minutes, ultrasonic oscillation for 30 minutes; after completion, pour the sample into polytetrafluoroethylene In a reaction kettle with the substrate as the substrate, react at 120°C for 24 hours, cool to room temperature under natural conditions, and after filtration, place the porous ceramsite in dilute hydrochloric acid solution for pickling, and then wash with deionized water until the porous ceramsite Neutral; put porous ceramsite in N 2 Sm, N co-doped TiO can be obtained by high-temperature calcination at 600 °C in an atmosphere furnace 2 Nanotube photocatalytic ceramsite.

[0069] Among them, Sm doped TiO 2 The nano powder is prepared by the first method, and the porous ceramsite ...

Embodiment 2

[0071] A method for preparing photocatalytic ceramsite, the preparation method of this embodiment is the same as that of embodiment 1, the only difference is: Sm doped TiO 2 The nano powder is prepared by the (second) method, and the porous ceramsite is prepared by the (second) method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com