Ti<3+> self-doped titanium dioxide photocatalyst and preparation method thereof

A technology of titanium dioxide and photocatalyst, which is applied in the field of photocatalytic materials, can solve the problems of complex instruments and difficult storage of reducing agents, and achieve the effects of low equipment requirements, good photocatalytic activity, and not easy to fail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

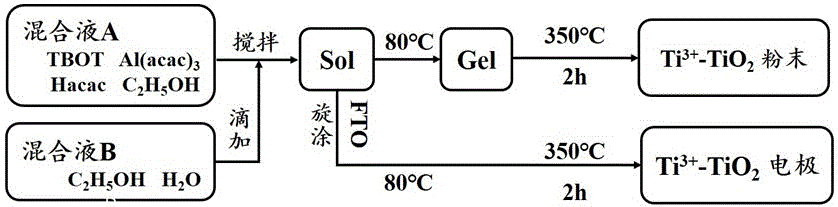

[0027] Measure 6 ml of butyl titanate, 2 ml of acetylacetone, 18 ml of ethanol and 2.92 g of aluminum acetylacetonate, mix and magnetically stir for 1 hour to obtain a mixed solution A. Mixture B containing 30 ml of ethanol and 2 ml of water was prepared in the same way. Under magnetic stirring, slowly drop the mixed solution B into the mixed solution A through a titration funnel to obtain a mixed, uniform and transparent sol. The prepared sol was left to stand for 48 hours, dried with an infrared lamp to obtain a gel, and then ground into powder. The obtained powder was placed in a magnetic boat, and annealed at 350°C for 2 hours at a heating rate of 10°C per minute in a muffle furnace to obtain self-doped titanium dioxide powder directly.

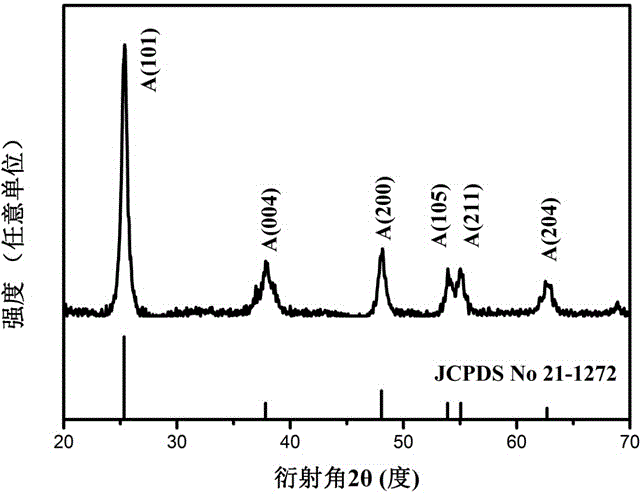

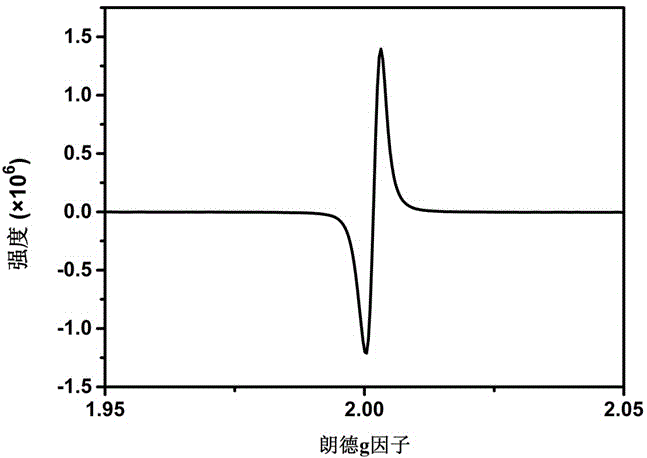

[0028] The X-ray diffraction spectrum of the sample ( figure 2 ) is consistent with the anatase phase titanium dioxide standard card, indicating that the sample is anatase phase titanium dioxide; electron paramagnetic resonance spectru...

Embodiment 2

[0030] Measure 6 ml of butyl titanate, 2.5 ml of acetylacetone, 24 ml of ethanol and 0.58 g of aluminum acetylacetonate, mix and magnetically stir for 1 hour to obtain a mixed solution A. Mixture B containing 40 ml of ethanol and 3 ml of water was prepared in the same way. Under magnetic stirring, slowly drop the mixed solution B into the mixed solution A through a titration funnel to obtain a mixed, uniform and transparent sol.

[0031] Clean the FTO conductive glass with 40~70% ethanol for 3 times, and dry it to get the FTO conductive glass with a clean surface. The sol was spin-coated on a clean FTO conductive glass, dried and annealed at 350°C for 1 hour to obtain a sample electrode sheet. Connect the sample electrode sheet to the copper wire with conductive silver glue, and then encapsulate it with insulating silica gel as the working electrode. The photoelectrochemical test was carried out in a 3-electrode system, with a platinum plate as the counter electrode and Ag / A...

Embodiment 3

[0034] Measure 7 ml of butyl titanate, 3 ml of acetylacetone, 36 ml of ethanol and 5.84 g of aluminum acetylacetonate, mix and magnetically stir for 1 hour to obtain a mixed solution A. Mixture B containing 30 ml of ethanol and 4 ml of water was prepared in the same way. Under magnetic stirring, slowly drop the mixed solution B into the mixed solution A through a titration funnel to obtain a mixed, uniform and transparent sol. The obtained powder was placed in a magnetic boat and annealed at 450°C for 4 hours at a heating rate of 10°C per minute in a muffle furnace to obtain self-doped titanium dioxide powder directly.

[0035] The photocatalytic efficiency was evaluated by UV-vis photodegradation of methylene blue. Weigh 10 mg of the sample, and ultrasonically mix it with 10 ml of 5 mmol / L methylene blue solution in a quartz reaction tube for 20 minutes. The mixed reaction solution was stirred for 2 hours in a dark state to reach adsorption-desorption equilibrium. The reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com