Method for removing iron and whitening for iron-containing attapulgite clay

A technology of attapulgite clay and attapulgite, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc., can solve the problems of affecting product quality, waste of medicine, reduction of reducibility, etc., to improve the effective utilization rate, Intensified collision, consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

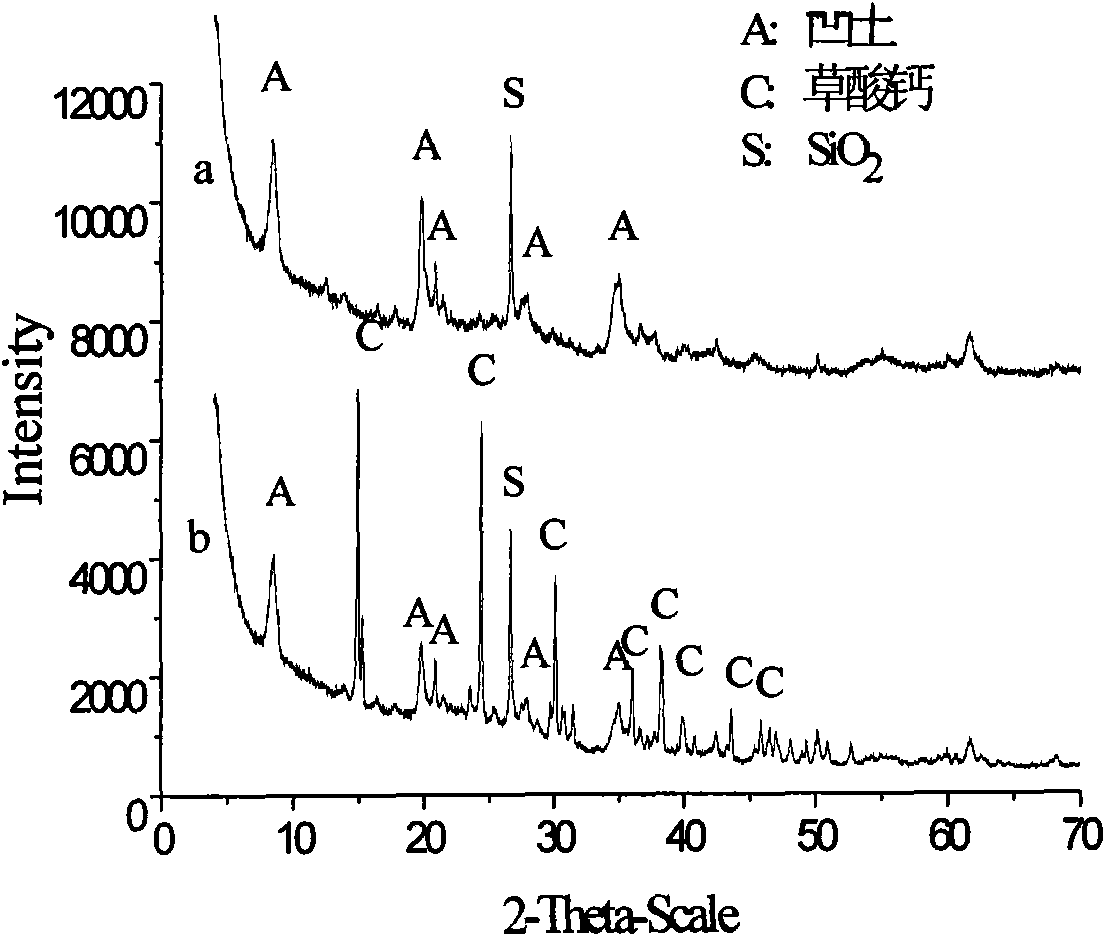

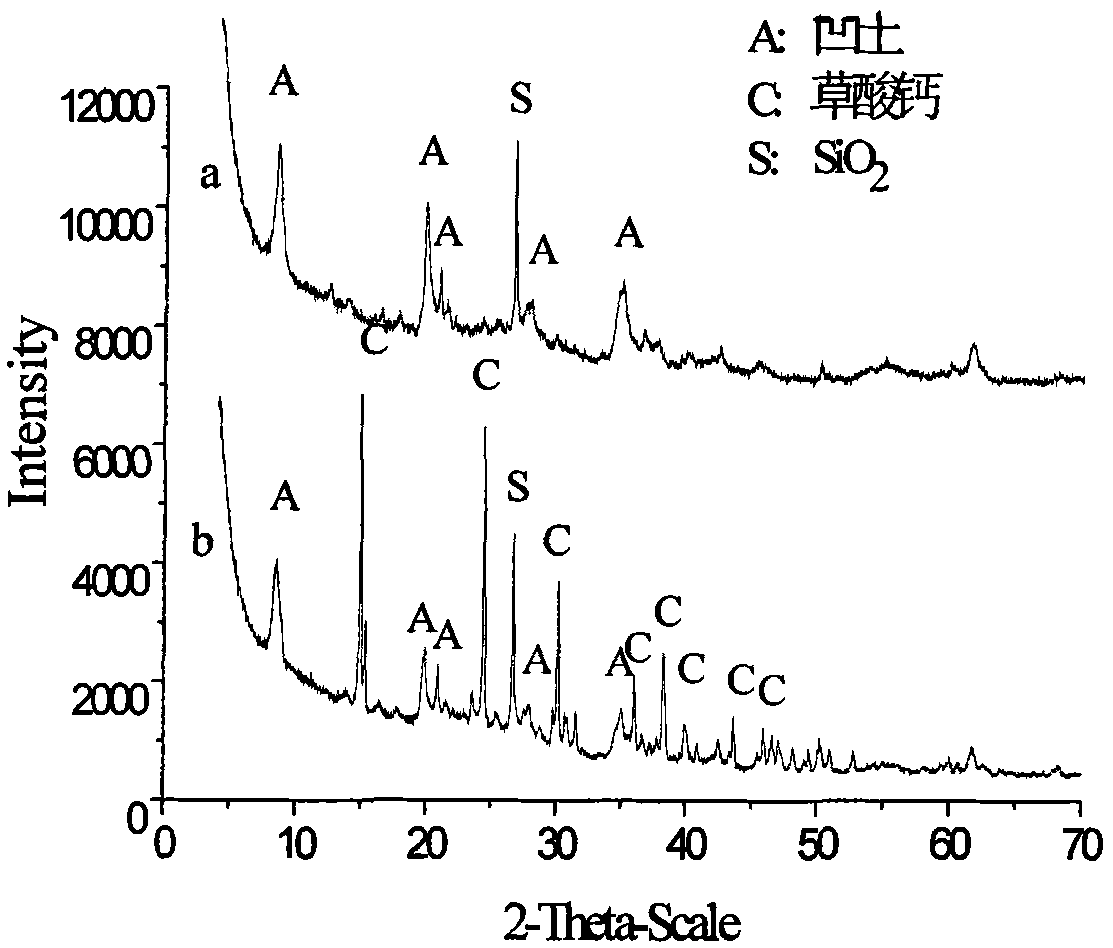

[0012] Take Gansu attapulgite clay (content of more than 40%, whiteness of 28.9%) as an example, the mineral powder is passed through a 100-mesh sieve and activated at 300°C for 1 hour; it is acidified with 3% sulfuric acid for 4 hours to solidify The liquid ratio is 8:1, the temperature is 60°C, washing is performed after acidification, and the pH value is controlled at about 6-7. After separation with a centrifuge, it is dried at 105°C and then ground through an 80-100 mesh sieve.

[0013] Put the acidified mineral powder into a 10% concentration of ore slurry into the reaction vessel, add 0.5mol / L oxalic acid, 3% titanium trichloride, and put it in a microwave oven with a temperature of 50°C and a power of 800W. Liquid phase acidification and pyrolysis lasted for 10 minutes, and then acidified in a reflux device for 40 minutes, then centrifuged and washed, and finally at 105°C, the product was obtained with a whiteness of 65.9%.

Embodiment 1-2

[0015] Take Gansu attapulgite clay (with a content of 40% or more and a whiteness of 28.9%) as an example. The mineral powder is passed through a 100-mesh sieve and activated at 700°C for 1 hour; it is acidified with 8% sulfuric acid for 4 hours. The liquid ratio is 8:1, the temperature is 60°C, washing is performed after acidification, and the pH value is controlled at about 6-7. After separation with a centrifuge, it is dried at 105°C and then ground through an 80-100 mesh sieve.

[0016] Put the acidified mineral powder into a 30% concentration of ore slurry into the reaction vessel, add 1.5mol / L oxalic acid, 5% titanium trichloride, and put it in a microwave oven with a temperature of 85°C and a power of 600W. Liquid phase acidification pyrolysis lasts for 8 minutes, and then acidification in a reflux device for 40 minutes, then centrifugal filtration, washing, and finally at 105° C., the product is obtained with a brightness of 73.6%.

Embodiment 2-1

[0018] Take Gansu attapulgite clay (content of more than 40%, whiteness of 28.9%) as an example, the mineral powder is passed through a 100-mesh sieve and activated at 500°C for 1 hour; it is acidified with 3% sulfuric acid for 4 hours to solidify The liquid ratio is 8:1, the temperature is 60°C, washing is performed after acidification, and the pH value is controlled at about 6-7. After separation with a centrifuge, it is dried at 105°C, and then ground through an 80-100 mesh sieve.

[0019] The acidified mineral powder is prepared into a 10% concentration of ore slurry into the reaction vessel, 0.5mol / L oxalic acid, 3% titanium trichloride are added, and placed in a fixed reflux device, and the liquid is carried out at a temperature of 85°C. The phase reflux acidification pyrolysis lasts for 150 minutes, then centrifugal filtration and washing are performed, and finally the product is obtained at 105°C with a whiteness of 65.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com