Patents

Literature

57results about How to "Intensified collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

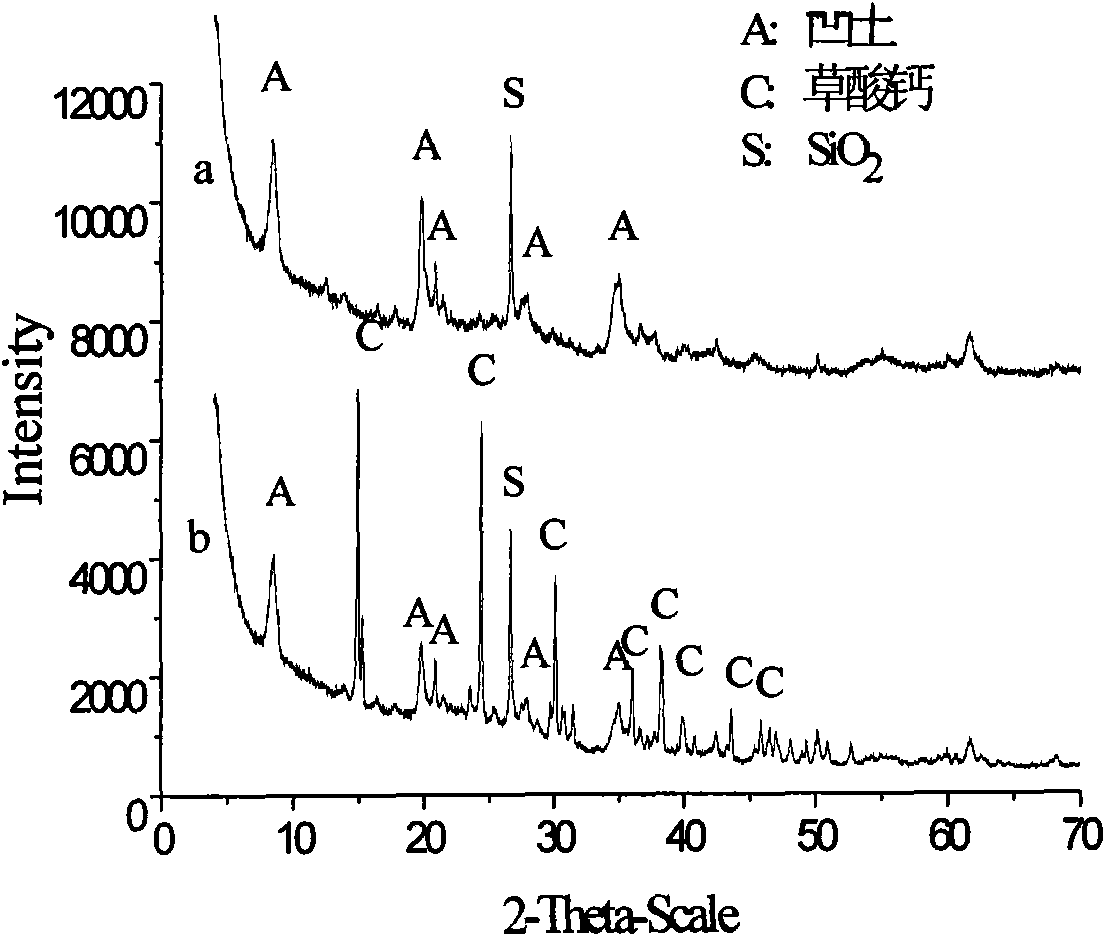

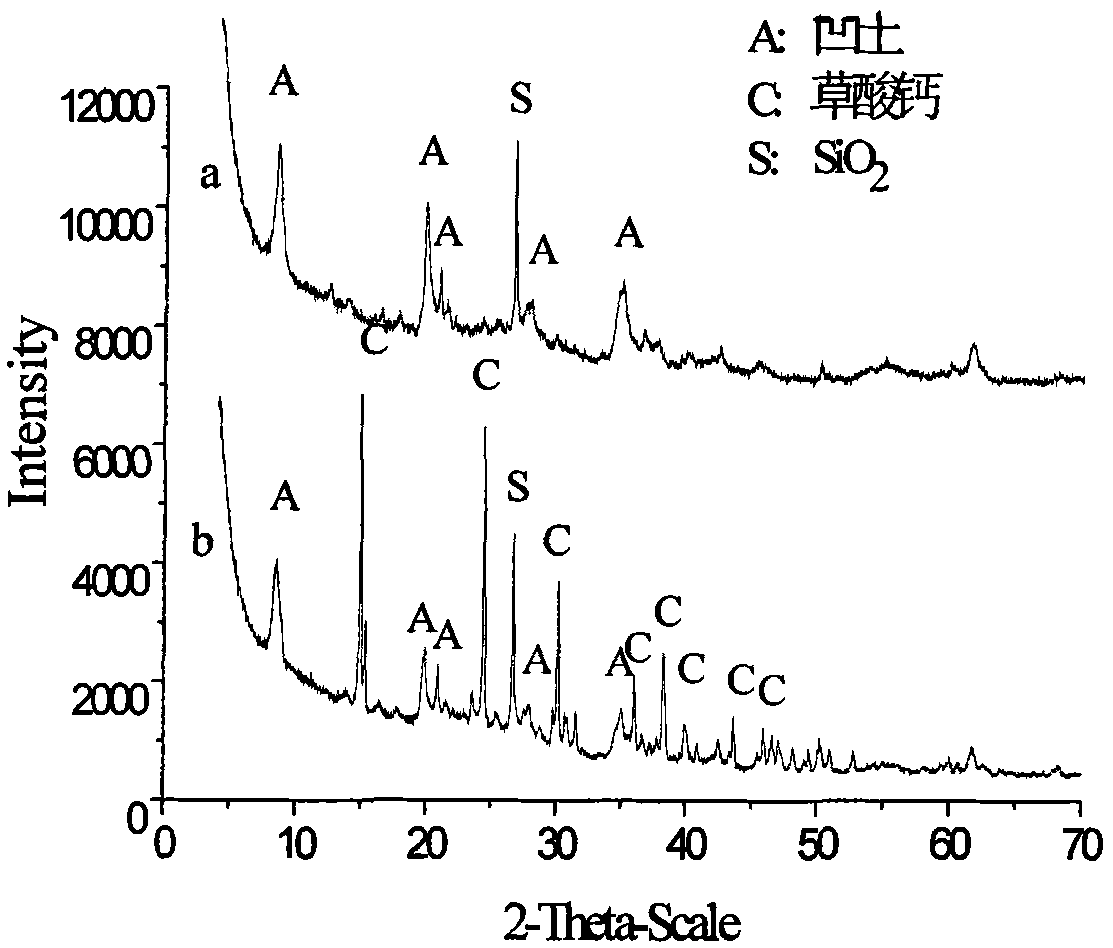

Method for removing iron and whitening for iron-containing attapulgite clay

InactiveCN101818000AEfficient removalIntensified collisionPigment physical treatmentDistilled waterSlurry

The invention relates to a method for removing iron and whitening for iron-containing attapulgite clay, comprising the following steps of: (1) selecting ore the content of attapulgite of which is more than 40%, crashing the attapulgite clay, and screening the attapulgite clay by a 100-mesh sieve, roasting and activating the attapulgite clay for 1 hour at the temperature of 300 to 700 DEG C; (2) acidulating the attapulgite clay after roasting treatment by 3 to 8% sulfuric acid , wherein the mass ratio of the sulfuric acid solution to the attapulgite clay is 8:1; placing the attapulgite clay in the sulfuric acid, stirring and soaking for 4 hours at the temperature of 60 DEG C, then washing for many times by utilizing distilled water, controlling the pH value to be 6.0 to 7.0, drying at the temperature of 105 DEG C, and then grinding, screening by a 80 to 120 mesh sieve; and (3) preparing the attapulgite clay after acidification to 10 to 30% ore slurry, placing the ore slurry into a reaction vessel, adding oxalic acid with the concentration of 0.5 to 1.5 mol / L and 3 to 5% titanium trichloride, heating reaction vessel for 8 to 150 minutes, acidulating for 40 to 50 minutes, and centrifuging, washing and filtering after reaction, and drying at the temperature of 105 DEG C to obtain the white attapulgite clay.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

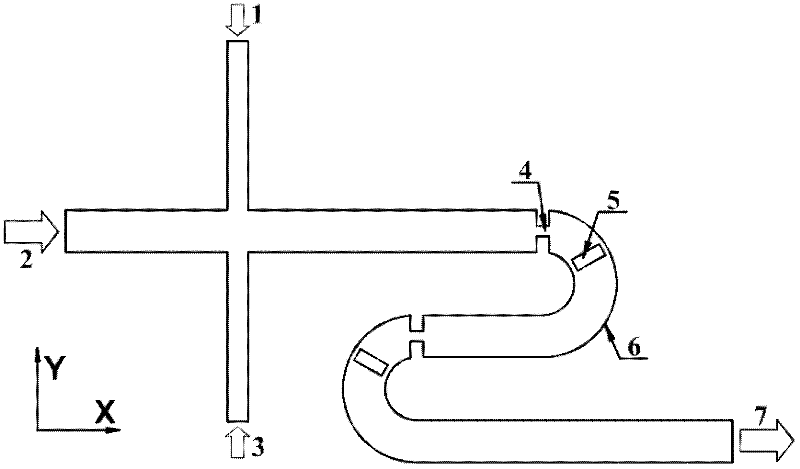

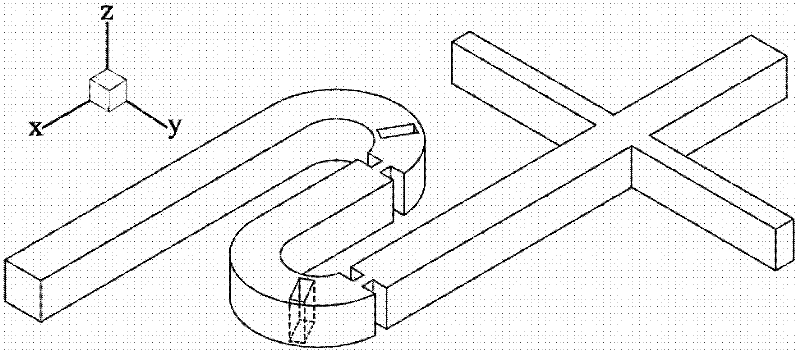

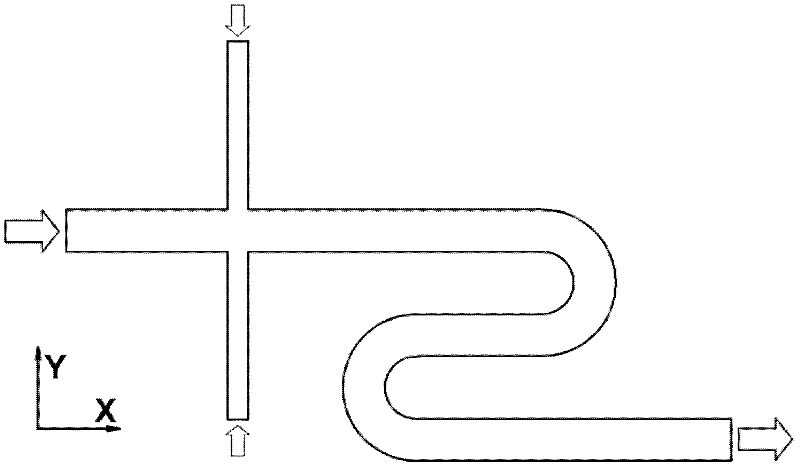

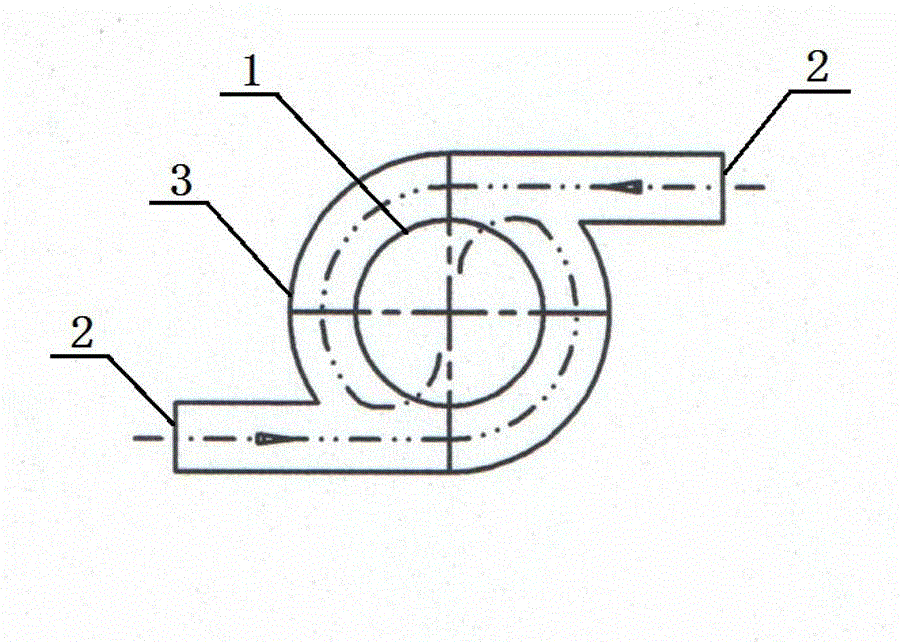

Planar passive micro mixer based on vortex forming structure enhanced mixing

InactiveCN102233241AIncrease contact areaIncrease disturbanceFlow mixersMixing methodsMicrofluidic chipMICRO MIXER

The invention discloses a planar passive micro mixer based on vortex forming structure enhanced mixing, relating to the field of micro fluid mixing in micro total analysis systems and micro fluid control chips as well as the related fields. The micro mixer is formed by connecting a straight passage, a cross passage, a first C-shaped passage and a second C-shaped passage; a passage outlet is formed at a straight passage outlet connected with the second C-shaped passage, and vortex forming structures are arranged in the C-shaped passages; and the end arm of the cross passage, which is opposite to the connected C-shaped passage, is provided with a second passage inlet (2), and the end arm vertical to the end arm is provided with a first passage inlet (2) and a third passage inlet (3) respectively. Compared with a planar passive micro mixer without the vortex forming structures, the planar passive micro mixer based on vortex forming structure enhanced mixing has the advantage of obviously enhancing the mixing strength of the micro fluid in the passages because several kinds of vortex generated by the vortex forming structures are generated in different dimensional planes respectively.

Owner:BEIJING UNIV OF TECH

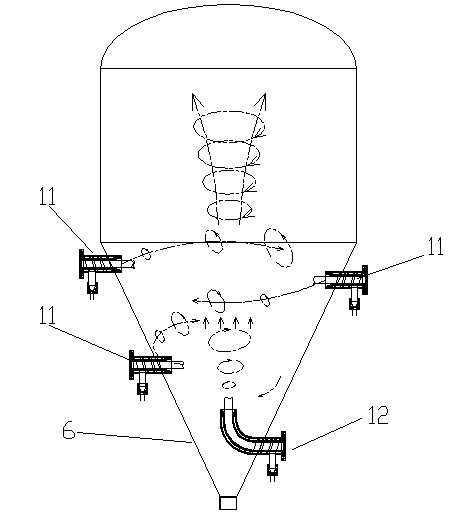

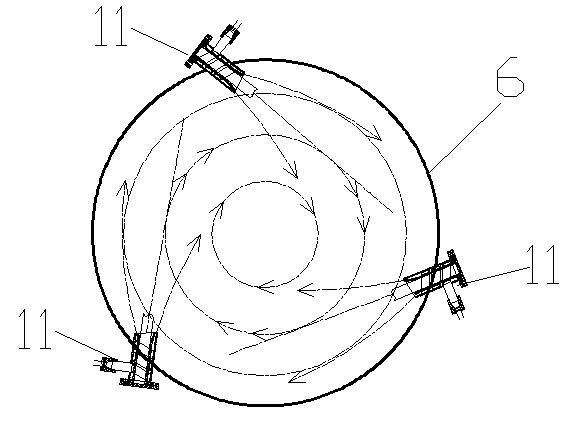

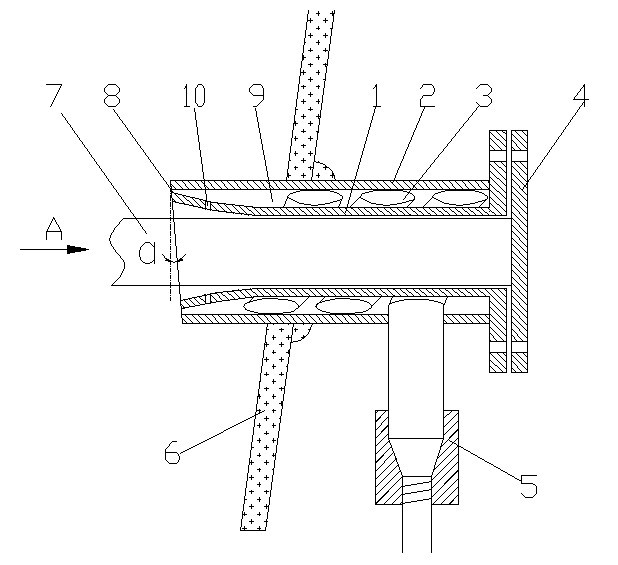

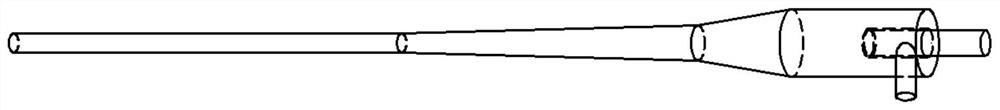

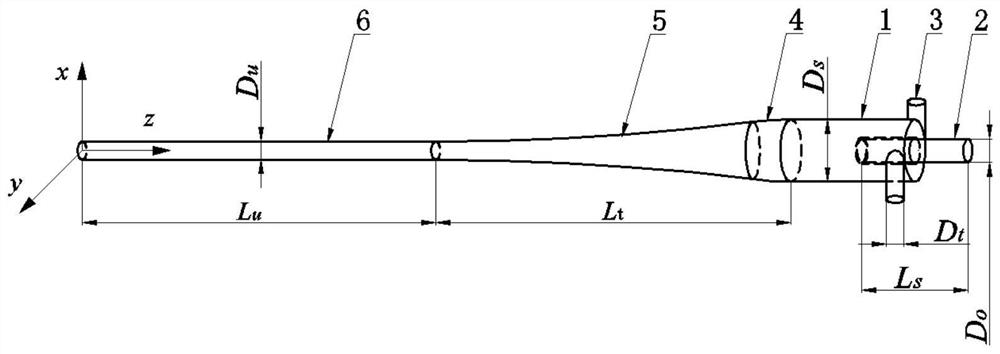

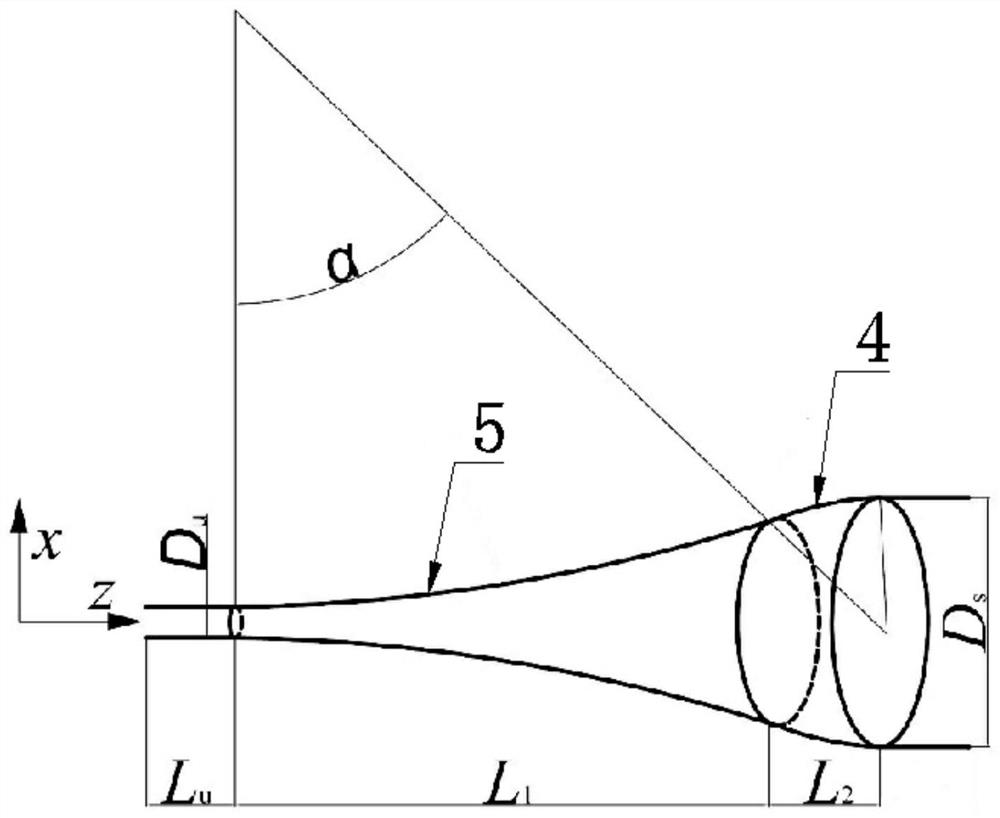

Tornado blowing method and cyclone device thereof

ActiveCN101962108AEfficient initial natural stackingThe initial natural stacking state is simpleLarge containersImpellerEngineering

The invention discloses a tornado blowing method and a cyclone device thereof. Tornado disturbance flow is ejected by the cyclone device to perform blowing intervention on stacked materials. According to the characteristic and principle that the attack of tornado is sudden, the tornado has violent destructive power, and generated wind can release huge energy in a concentrating way in a small area, in a local spacial range, such as an enclosed bulk tank cylinder and other containers, a dust material agitating mode capable of releasing huge energy in the concentrating way in short time is adopted, the gas consumption can be reduced and the initial natural stacking state of the dust material can be efficiently intervened by means of the violent destructive powder, so the method is a simple, convenient and high-efficiency dust removing method. Compared with modes of mechanically rotating vanes or guide plates, which have the disadvantages of high wear rate and high explosion risk factor, the method is more similar to the tornado forming environment, reliable and safe.

Owner:CISDI ENG CO LTD +1

Biological agent for glutamate wastewater treatment

InactiveCN105039228APromote degradationHigh activityFungiBacteriaAspergillus nigerBacteroides species

The invention relates to a biological agent for glutamate wastewater treatment. The biological agent is formed by mixing aerobic denitrifier, bacillus, aspergillus niger, rhodococci, alcaligenes faecalis, streptomyces lateritius, Candida albicans and an adsorbent carrier. The biological agent contains various microorganisms with the good degradation ability to non-biodegradable pollutants, all the bacteria are reasonably matched, the good degradation effect is achieved, and the wide application prospect is achieved.

Owner:内蒙古阜丰生物科技有限公司

Treatment method for dephosphorizing and denitrifying sewage

ActiveCN105859060AReduce dosageShorten the timeWater treatment parameter controlWater contaminantsBacillus cereusPseudomonas

The invention relates to a treatment method for dephosphorizing and denitrifying sewage. The method is characterized by carrying out treatment by combining a physical method and a biological agent, wherein the biological agent comprises the following raw materials in parts by weight: 5-7 parts of paracoccus denitrificans, 5-7 parts of saccharomyces cerevisiae, 4-5 parts of rhodococcus, 4-5 parts of bacillus amyloliquefaciens, 3-4 parts of clostridium papyrosolvens, 3-4 parts of penicillium ochrochloron, 2-3 parts of pseudomonas and 1-2 parts of bacillus cereus. The biological agent contains various microorganisms with excellent capacity of degrading refractory pollutants, is reasonable in compatibility of the strains, has good degrading effects and has a broad application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

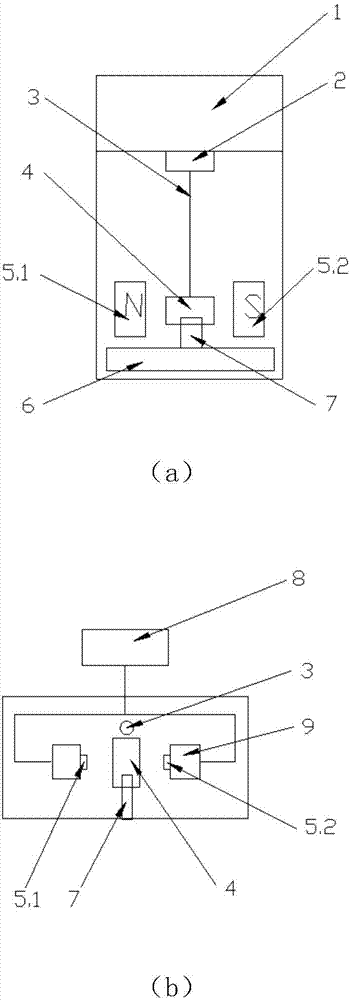

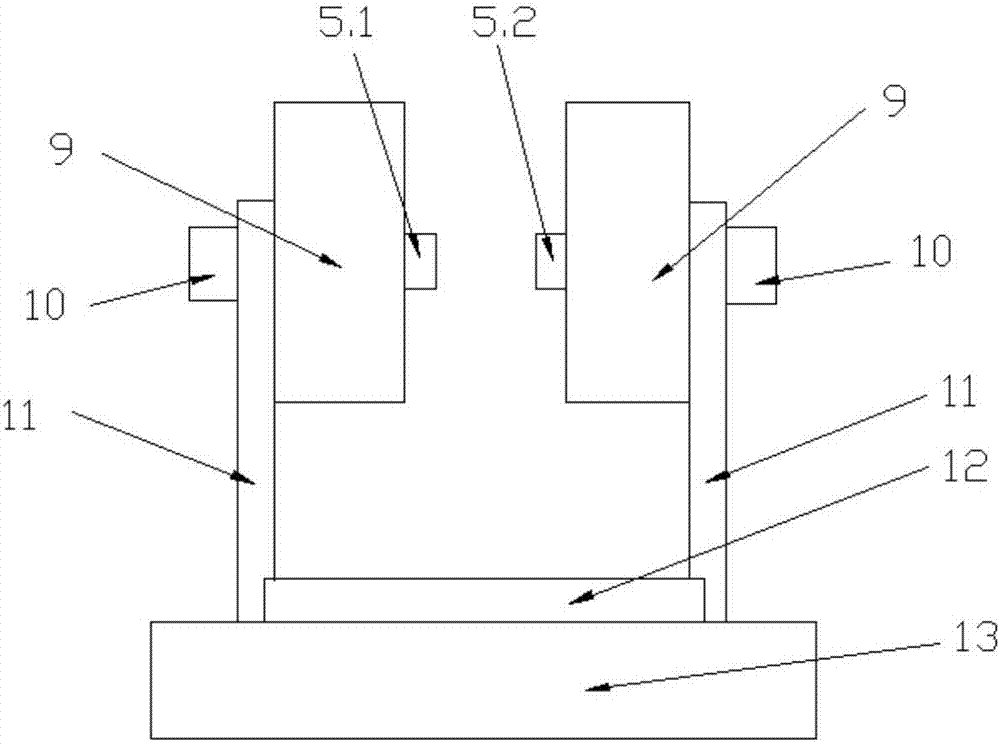

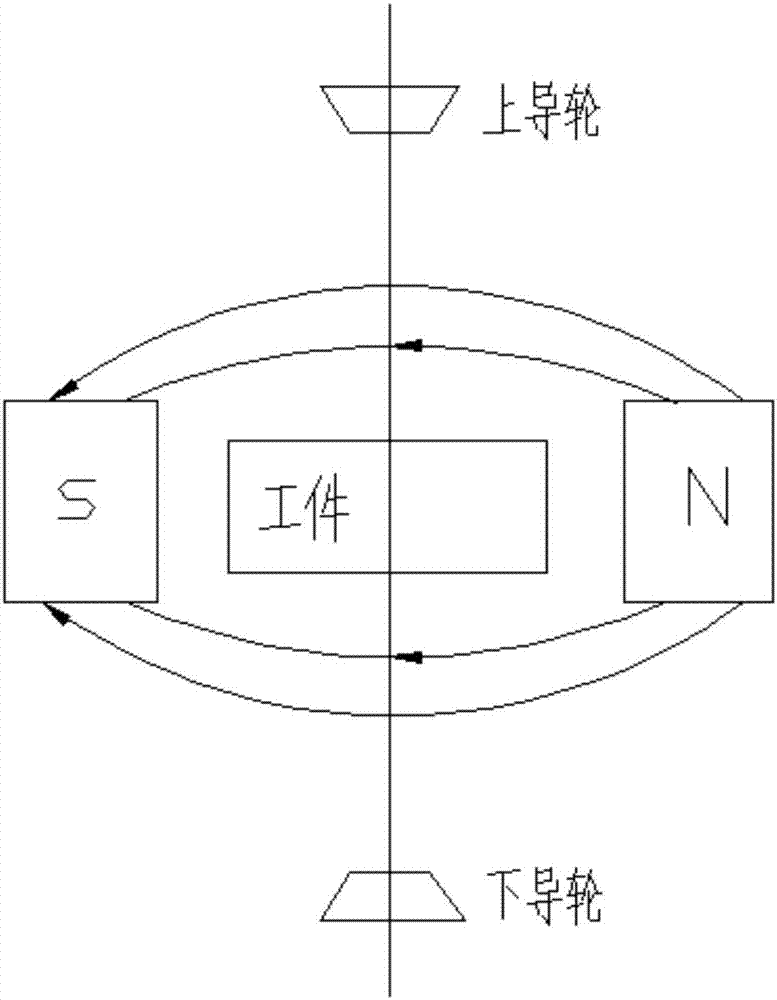

Auxiliary method and device for wire cut electrical discharge machining

The present invention discloses an auxiliary method and device for wire cut electrical discharge machining. The method comprises applying a magnetic field which is perpendicular to a machining direction and a wire electrode direction at the same time to a workpiece in a wire cut electrical discharge machining process. The device comprises a direct current excitation source and electromagnets. A discharge ion passage in wire cut electrical discharge machining is restricted and compressed through the applied magnetic field, and a lorentz force acting on the discharge ion passage and a lorentz force acting on a wire electrode are generated, so ion density of the discharge ion passage is raised, collision of charged ions in the discharge ion passage is intensified, discharge contact points of a working surface are increased, and a function of raising a material removal rate is achieved. Charged ion disturbances at surfaces of the electrodes are reduced through the magnetic field, stability of the discharge iron passage and discharge stability in wire cut electrical discharge machining are improved, and thus the surface quality of the manufactured workpieces is raised.

Owner:HUAZHONG UNIV OF SCI & TECH

Microbial preparation for processing industrial fermentation wastewater

InactiveCN105274024APromote degradationGood removal effectFungiBacteriaStreptomycesIndustrial fermentation

The invention relates to a microbial preparation for processing industrial fermentation wastewater. The microbial preparation is prepared by mixing nitrosobacterium, Trichoderma longibrachiatum Rifai, aerobic denitrifying bacterium, acinetobacter baumannii, aspergillus niger, alcaligenes faecalis, Streptomyces lateritius, Candida albicans, Paenibacillus polymyxa and an adsorbent carrier. The microbial preparation contains multiple microbes having excellent ability of degrading non-biodegradable pollutants. Through reasonable compatibility between various strains, the microbial preparation has a good degradating effect and has a wide application prospect.

Owner:张胜平

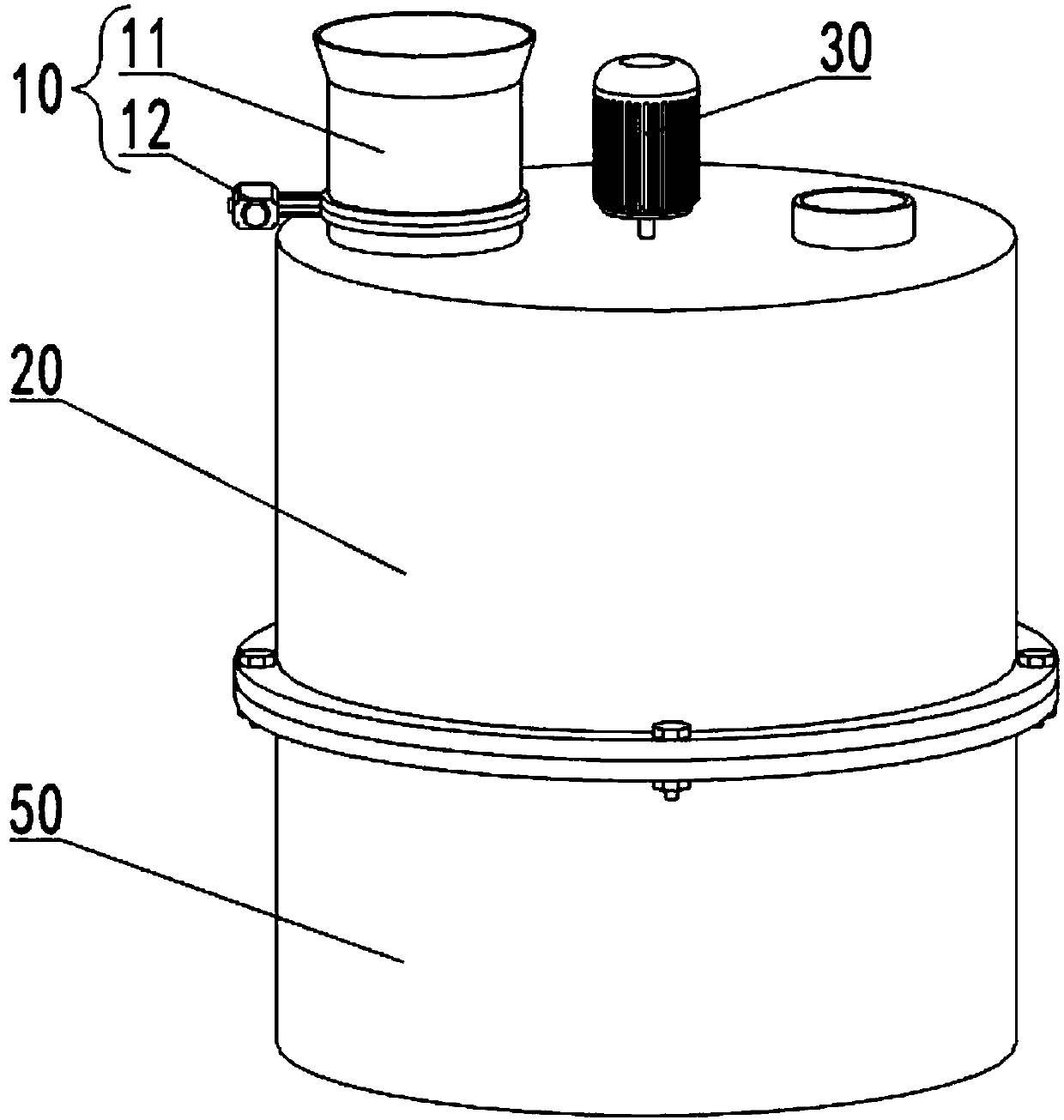

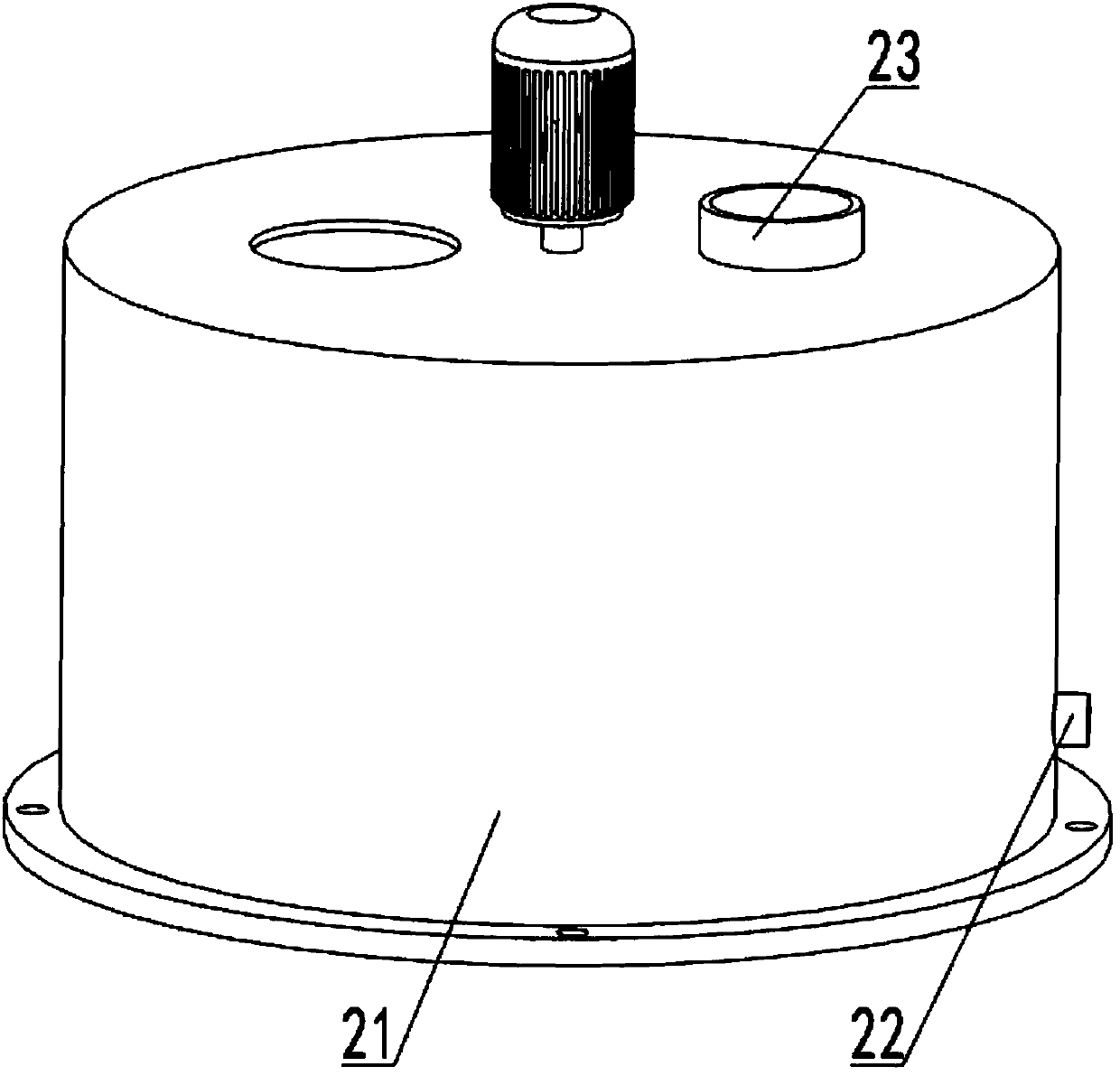

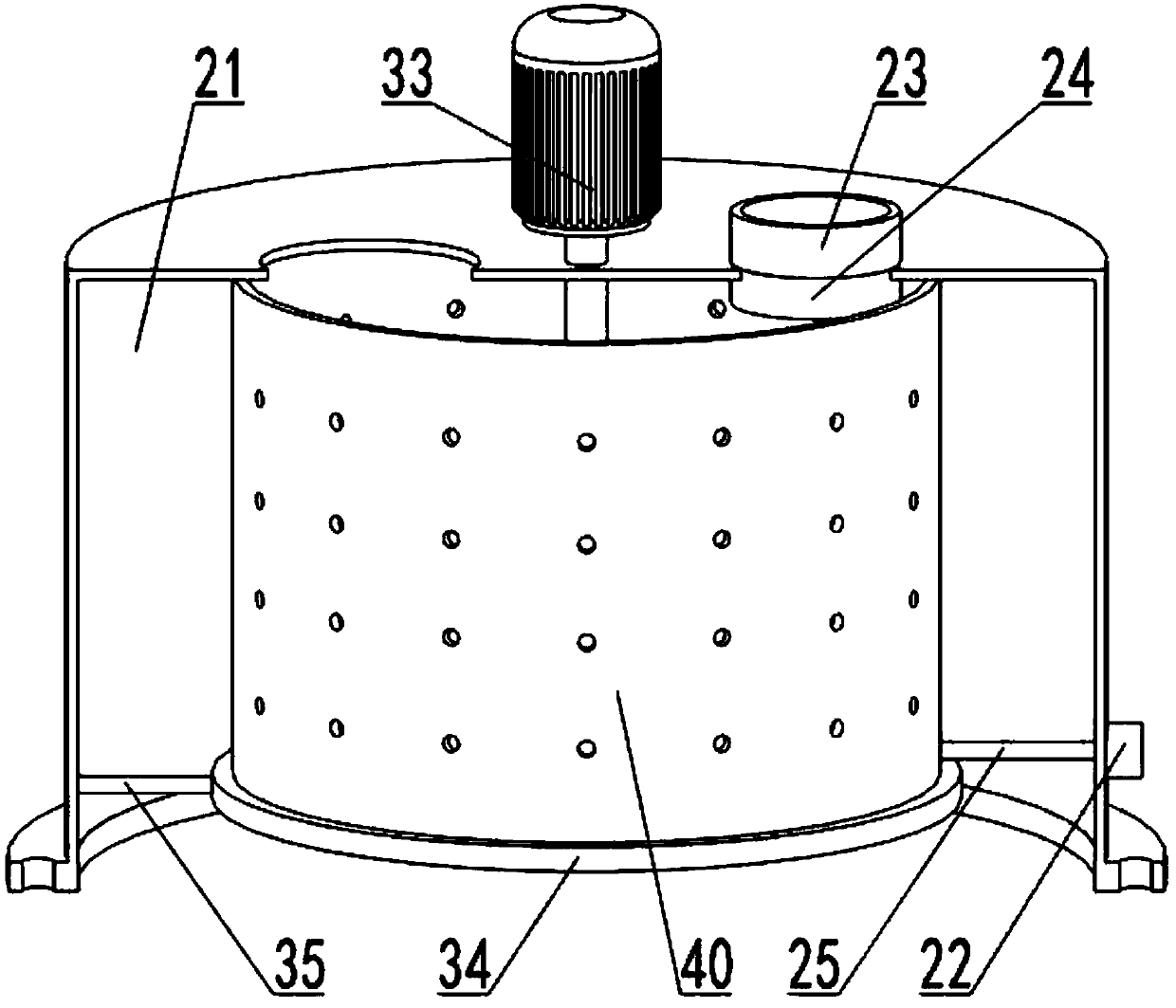

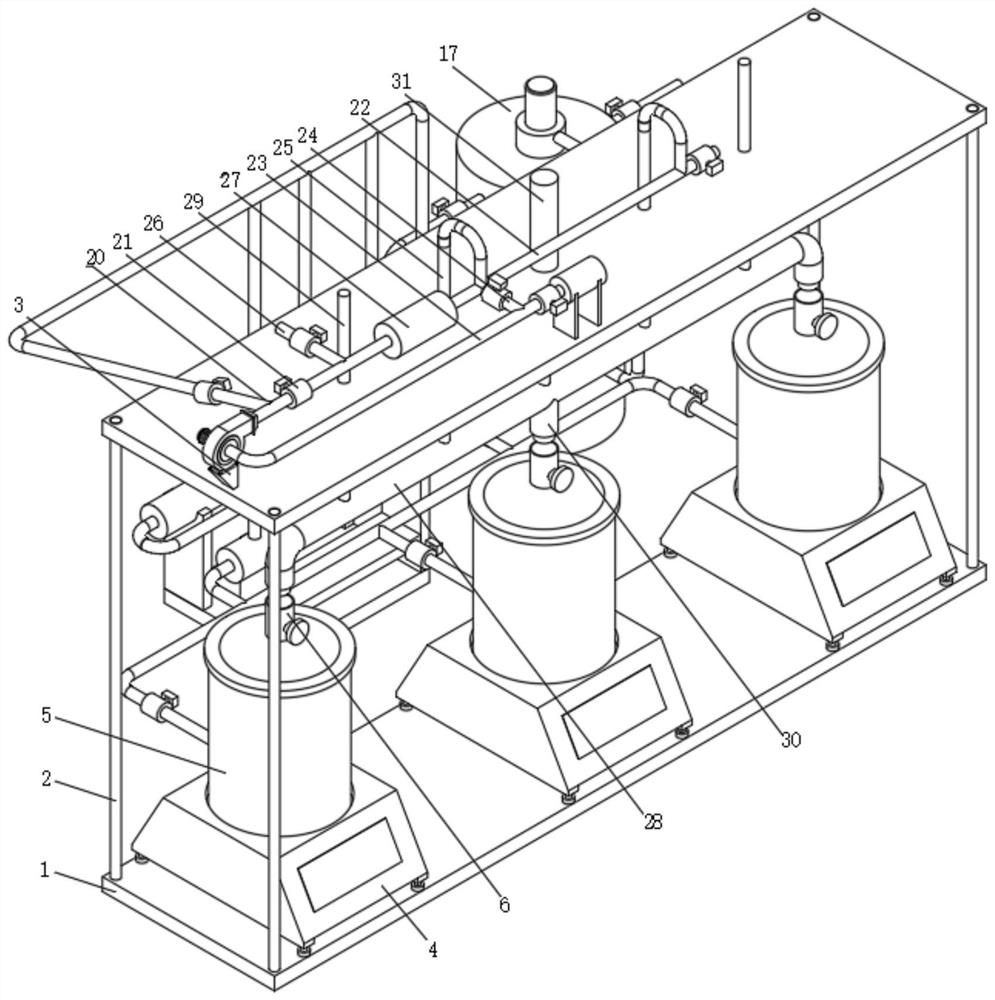

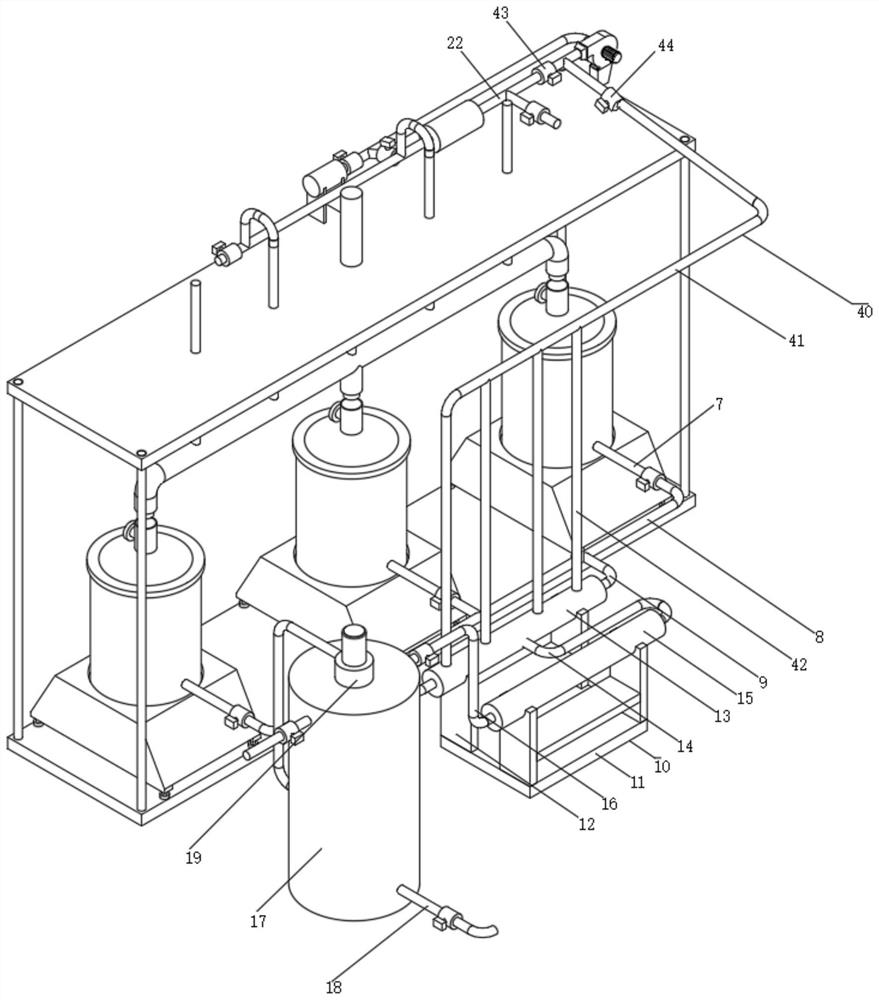

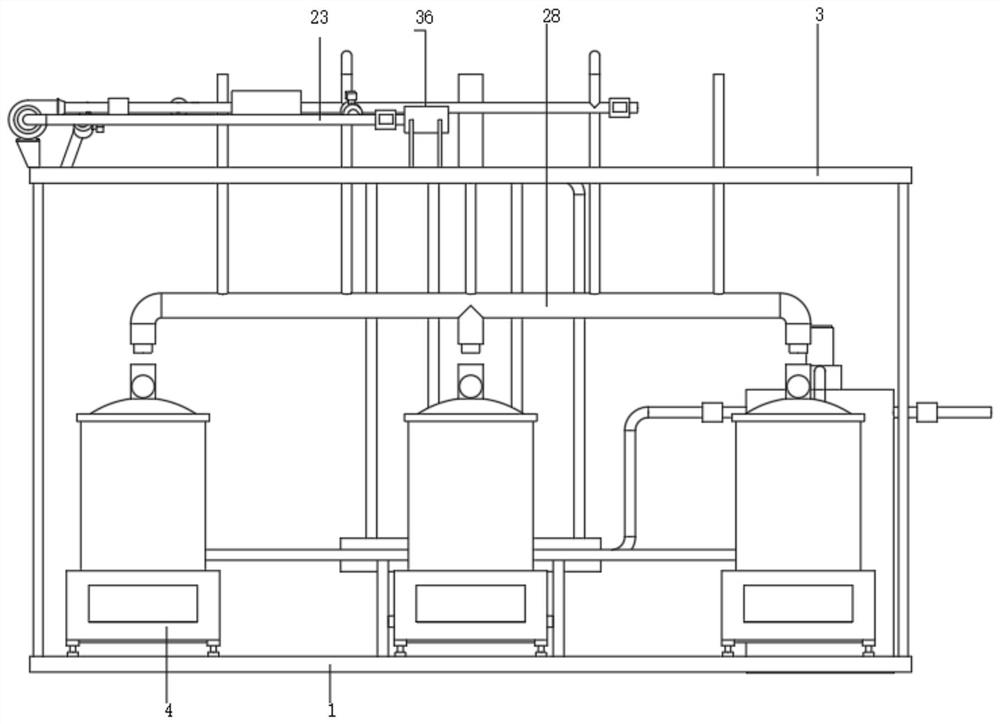

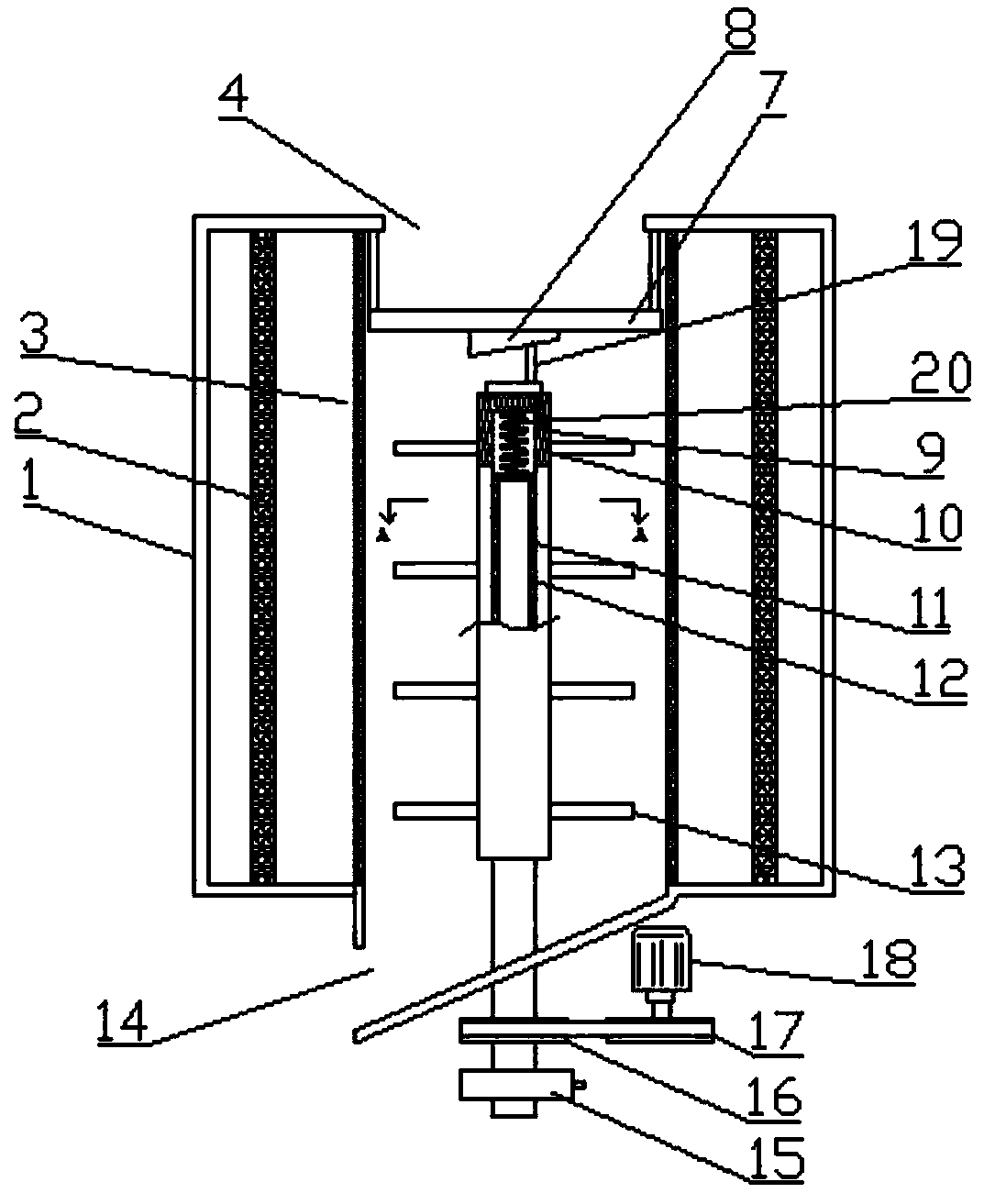

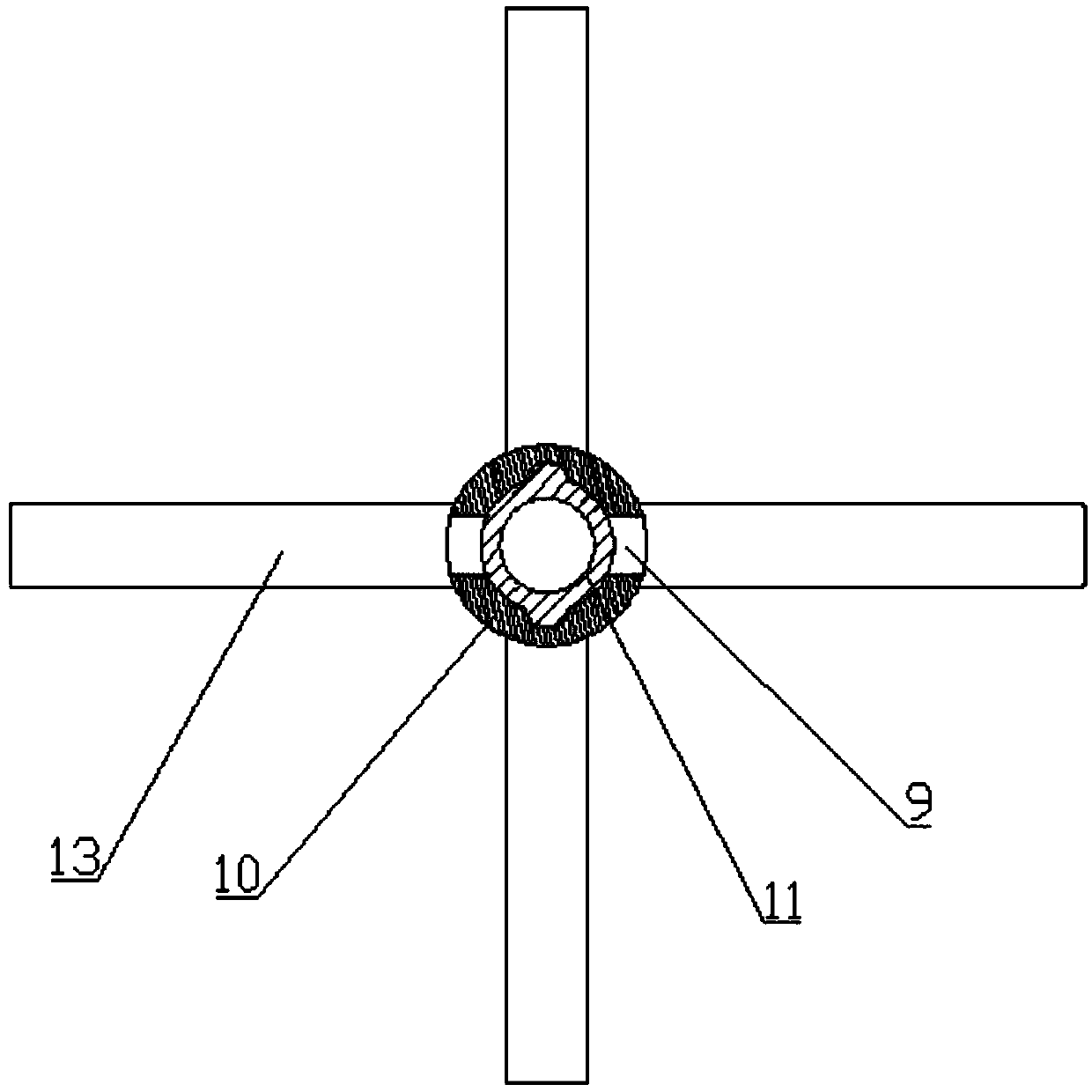

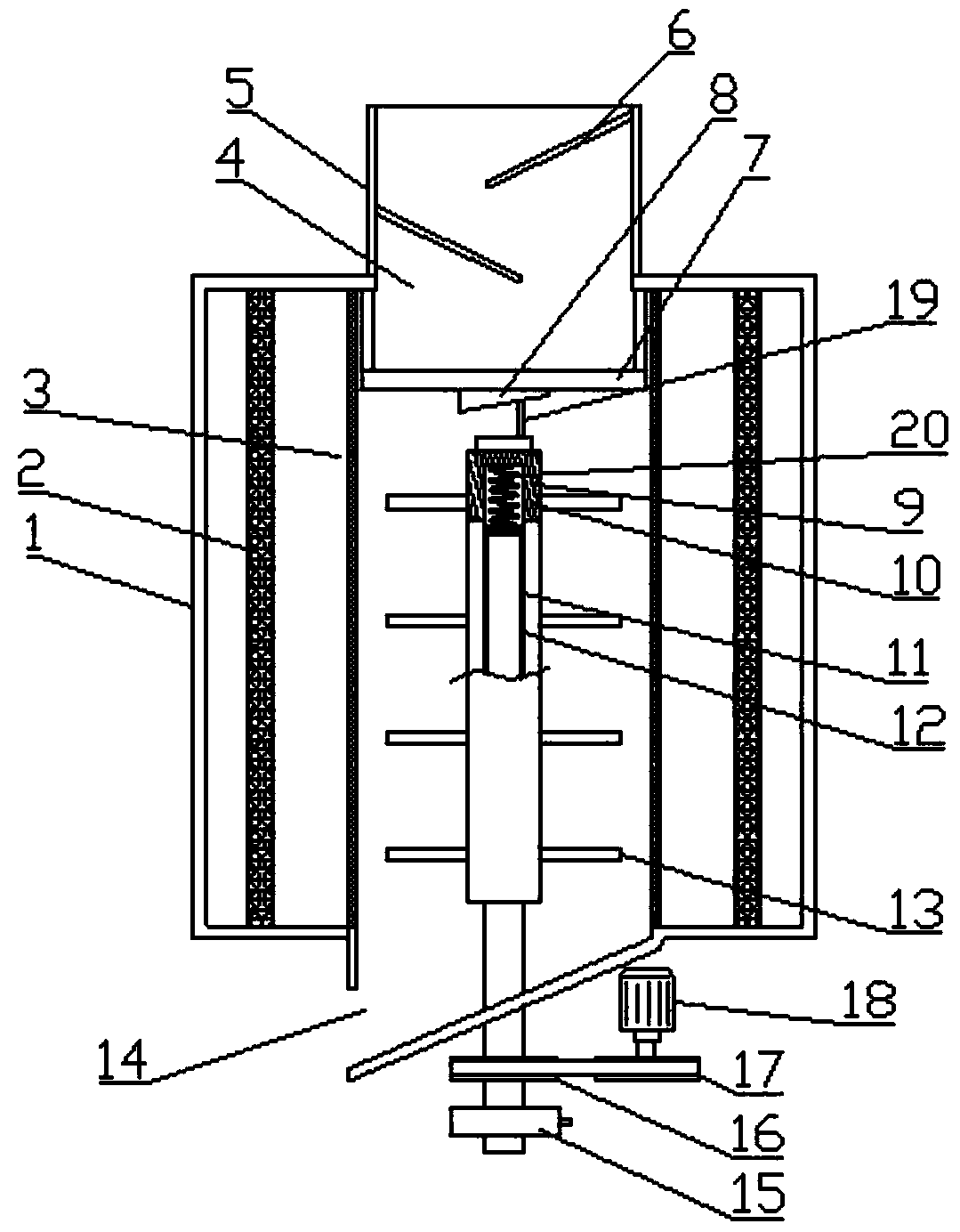

Particle logistics grinding equipment

PendingCN107670811AFast preparationEasy to prepareHollow article cleaningGrain treatmentsLogistics managementMetal particle

The invention belongs to the technical field of metal particle processing equipment, and particularly relates to particle logistics grinding equipment, which comprises a feeding mechanism, a fluidifying mechanism, a stirring mechanism, a screen mesh and a collecting bin. The fluidifying mechanism comprises a fluidifying bin; the fluidifying bin is connected with the feeding mechanism, can hold rawmaterials transferred by the feeding mechanism, and enables the raw materials to fluidify to a fluidifying state; the stirring mechanism comprises a stirring paddle; the stirring paddle is located inthe fluidifying bin and can shape raw material particles; the screen mesh is in a cylindrical shape and is located in the fluidifying bin; on the outer side of the stirring paddle, the upper end of the screen mesh is in seal connection with a top plate of the fluidifying bin, and the lower end of the screen mesh is in seal connection with the stirring mechanism; and the collecting bin is locatedunder the fluidifying bin and is connected with the fluidifying bin. By adopting the scheme, the prepared raw materials have uniform particle diameters, the performance is stable, and the accuracy ofa follow-up experiment result is ensured. In addition, the time and the labor are saved, and the experiment efficiency is improved.

Owner:HEBEI COLLEGE OF IND & TECH

Treating preparation suitable for high-concentration nondegradable wastewater

InactiveCN105198161APromote degradationHigh activityMultistage water/sewage treatmentWaste water treatment from food industryHigh concentrationPaenibacillus polymyxa

The invention relates to a treating preparation suitable for high-concentration nondegradable wastewater, which is prepared by mixing aerobic denitrifying bacterium, Paenibacillus polymyxa, Aspergillus niger, Rhodococcus, Bacillus foecalis alkaligenes, Streptomyces lateritius, Candida albicans, nitrococcus and an adsorbent carrier. The preparation contains multiple microbes having favorable degradation capacity for nondegradable pollutants; and due to the reasonable proportioning of the strains, the preparation has favorable degradation effect and has wide application prospects.

Owner:尤新军

Biological preparation for treating sodium glutamate fermentation sewage

ActiveCN105906169AReduce dosageShorten the timeTreatment using aerobic processesWater contaminantsBiotechnologyMonosodium glutamate

The invention relates to a biological preparation for treating sodium glutamate fermentation sewage. The biological preparation comprises a physical preparation and a complex microbial agent, wherein the complex microbial agent comprises the following components in parts by weight: 4-5 parts of Azotobacter chroococcum, 4-5 parts of phanerochaete chrysosporium, 5-6 parts of Bacillus amyloliquefaciens, 4-6 parts of Clostridium papyrosolvens, 3-4 parts of penicillium ochrochlorron, 3-4 parts of Pseudomonas aeruginosa and 2-3 parts of bacillus cereus. The biological preparation contains multiple microorganisms having excellent degradation capacity to non-biodegradable pollutants, and by virtue of reasonable compatibility of the strains, the good degradation effect is achieved, and the application prospect of the biological preparation is wide.

Owner:内蒙古阜丰生物科技有限公司

Biochemical preparation for treating threonine fermentation sewage

ActiveCN105921099AReduce dosageShorten the timeOther chemical processesSilicon compoundsBiotechnologyMicrobial agent

The invention relates to a biochemical preparation for treating threonine fermentation sewage. The biochemical preparation is characterized by comprising a physical adsorbent and a composite microbial agent, wherein the composite microbial agent is prepared from the following raw materials by a volume ratio: 6 to 7 parts of arthrobacter sp., 5 to 7 parts of pseudomonas stutzeri, 5 to 7 parts of rhodococcus sp., 4 to 5 parts of bacillus amyloliquefaciens, 4 to 5 parts of clostridium papyrosolvens and 3 to 4 parts of scenedesmus obliquus. The biochemical preparation contains multiple microorganisms having good degrading capability to recalcitrant pollutants; various strains are reasonably matched to realize a good degrading effect; the biochemical preparation has a broad application prospect.

Owner:内蒙古阜丰生物科技有限公司

Method for preparing sodium glutamate through concentrating continuous freezing isoelectric point crystallization

InactiveCN105087702AReduce consumptionIncrease productionMicroorganism based processesFermentationBiotechnologyAmino acid fermentation

The invention belongs to the technical field of amino acid fermentation, and discloses a method for preparing sodium glutamate through concentrating continuous freezing isoelectric point crystallization. The method comprises the following steps: 1) preparing a corynebacterium glutamicum seed solution; 2) preparing a brevibacterium lactofermentum seed solution; 3) mixing and stirring; 4) preparing sodium glutamate through fermentation; 5) implementing concentrating continuous freezing isoelectric point crystallization; and 6) processing waste liquid. The method disclosed by the invention is high in fermentation efficiency, low in industrial energy consumption and is energy-saving and emission-reducing.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

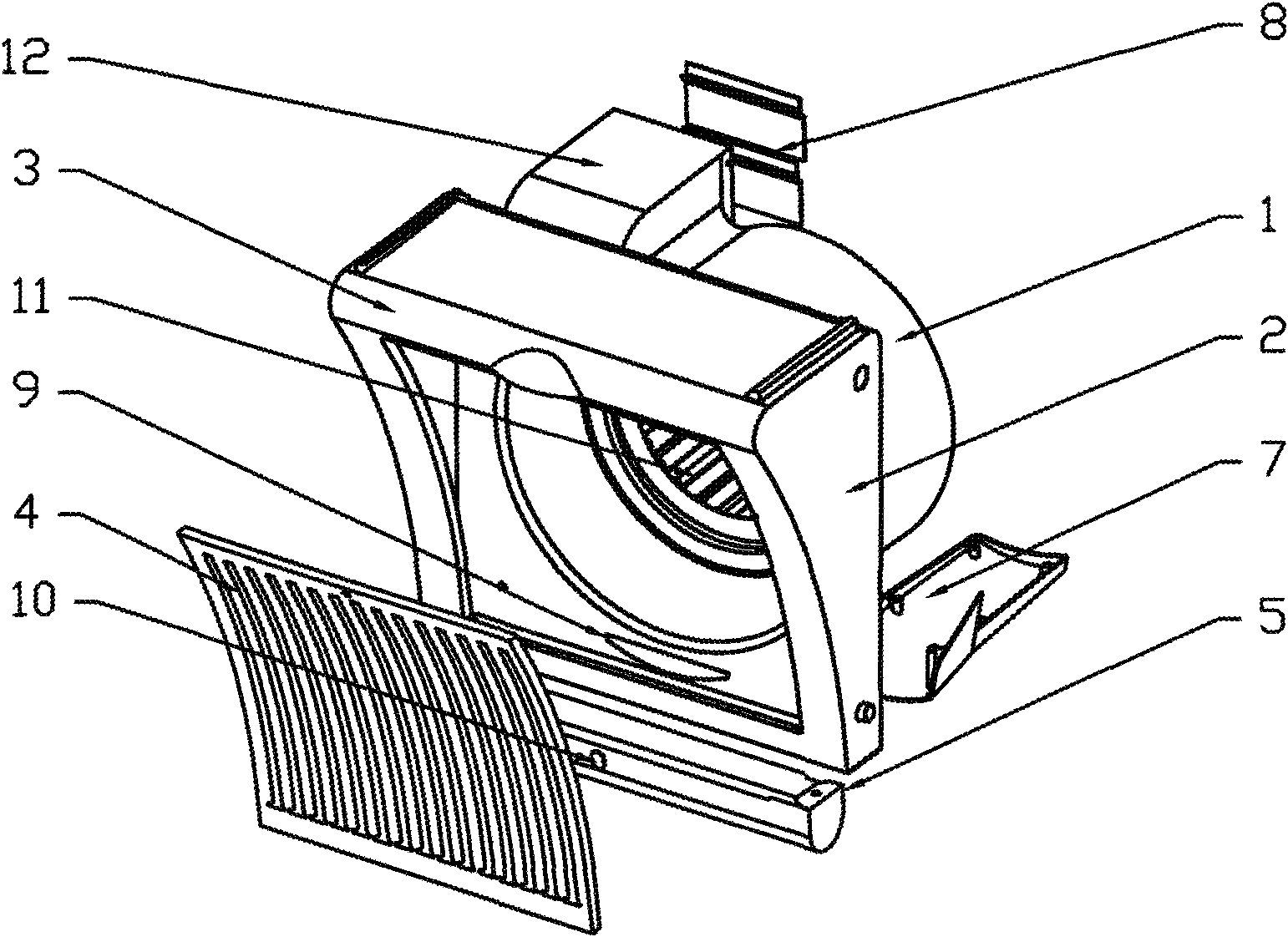

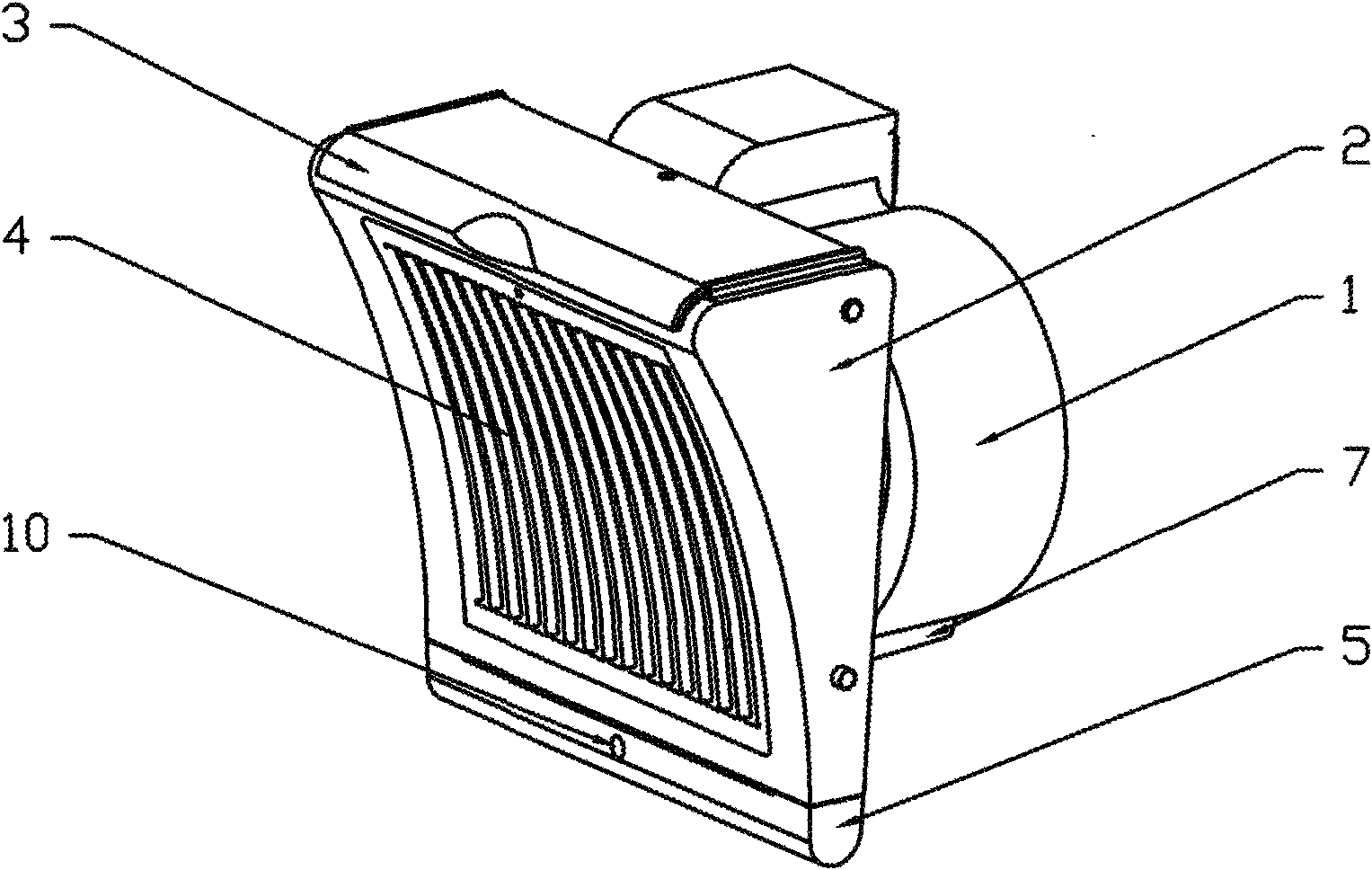

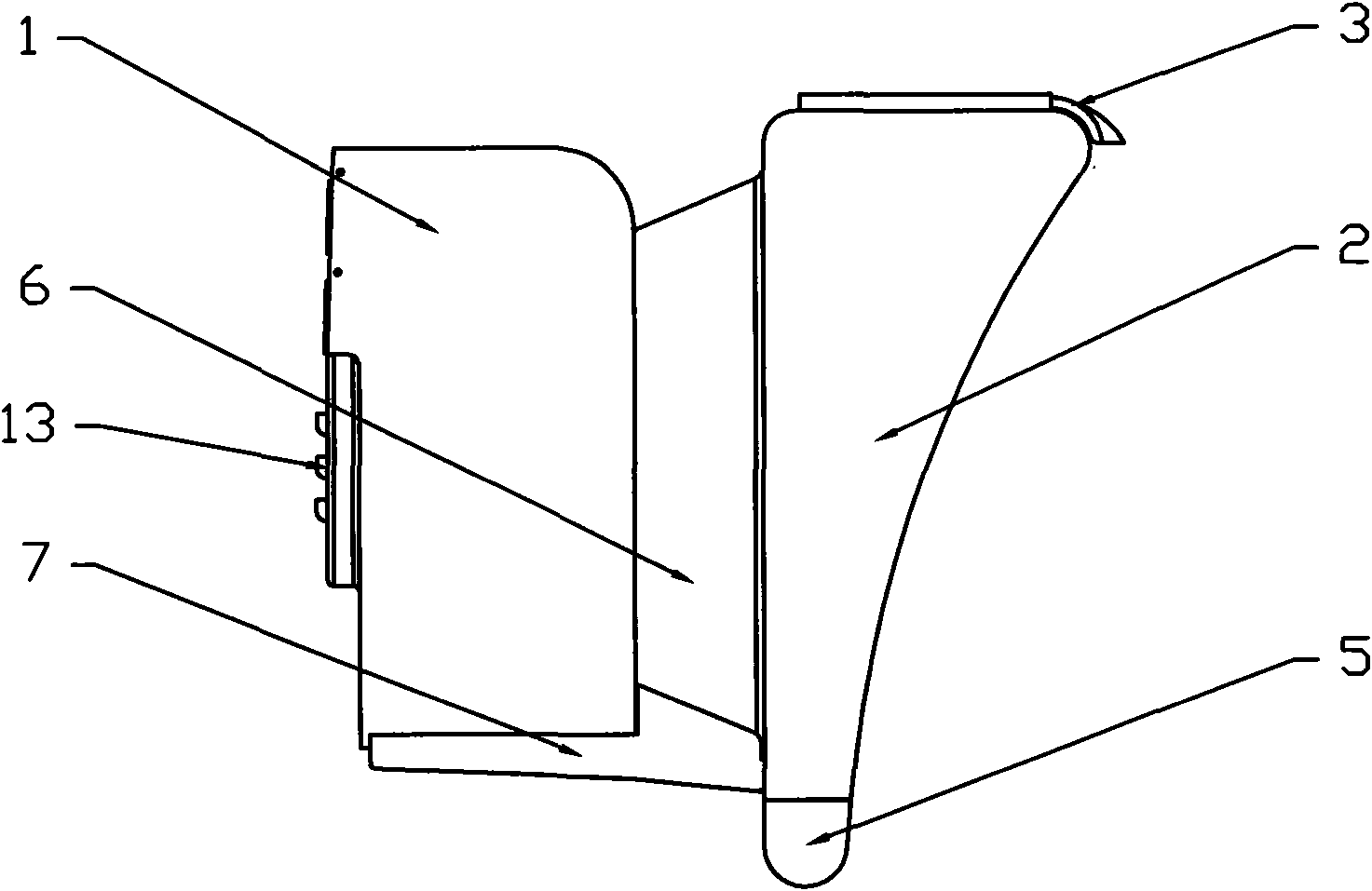

Turbine oil smoke absorbing fan

The invention discloses a turbine oil smoke absorbing fan composed of a main shell with an oil smoke absorbing air inlet, a power air drafting device connected with the main shell, and an air outlet. The power air drafting device is a turbine fan blade driven by a motor, a turbine shell connected with a main shell framework is arranged outside the turbine fan blade, and the turbine shell is a cylindrical structure. The air outlet is arranged at the side of the turbine shell and communicated with the inner cavity of the turbine shell integrally. The main shell is composed of a ventilating duct connected with the turbine shell, and an oil smoke absorbing cavity connected with the ventilating duct and extended forwards. A grid-type net is arranged at the air inlet at the front end of the oil smoke absorbing cavity. The invention adopts a technique that combines the turbine structure of a range hood with a main structure of an exhaust fan, not only has the advantage that the range hood highly effectively separates the oil smoke, but also inherits the advantages that the exhaust fan has a simple structure and small volume. The turbine oil smoke absorbing fan can not only separate the oil smoke for two times and greatly decrease the pollution levels of fan and air, but also greatly decrease cost.

Owner:GUANGDONG MACRO GAS APPLIANCE

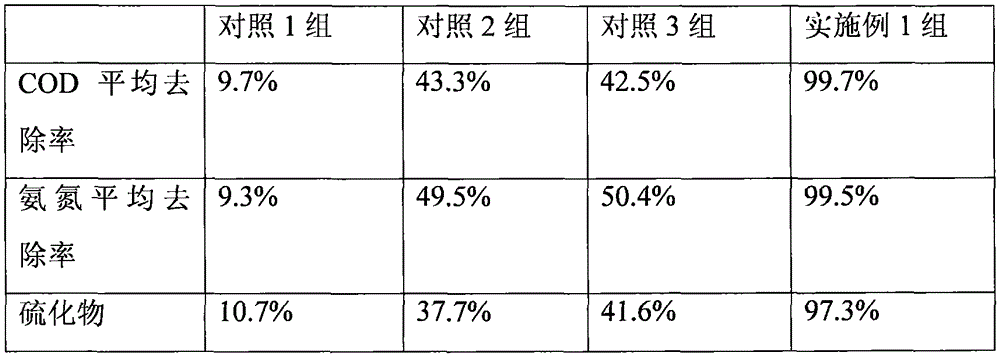

Treatment process of monosodium glutamate fermentation wastewater

ActiveCN105923921APromote degradationHigh activityTreatment involving filtrationMultistage water/sewage treatmentBiotechnologyMonosodium glutamate

The invention relates to a treatment process of monosodium glutamate fermentation wastewater. The wastewater is subjected to physical adsorption and composite bacteria treatment, wherein composite bacteria comprises the following components in parts by weight: 7 parts of azotobacter chroococcum, 5 parts of rhodococcus, 5 parts of bacillus amyloliquefaciens, 4 parts of clostridium papyrosolvens, 4 parts of penicillium ochrochloron, 3 parts of pseudomonas aeruginosa and 2 parts of bacillus cereus. As the composite bacteria contain various microorganisms that have an excellent degradation capability for refractory pollutants, and respective bacteria are combined reasonably, a good degradation effect is realized, and the treatment process of the monosodium glutamate fermentation wastewater has a broad application prospect.

Owner:内蒙古阜丰生物科技有限公司

Method for extracting gourmet powder through concentration isoelectric point technology

InactiveCN105039488AReduce consumptionIncrease productionOrganic compound preparationMicroorganism based processesBiotechnologyLactose

The invention belongs to the field of gourmet powder extracting technology in the biological fermentation technology and discloses a method for extracting gourmet powder through the concentration isoelectric point technology. The method comprises the following steps that firstly, a corynebacterium glutamicum seed solution is prepared; secondly, a brevibacterium lactofermentum seed solution is prepared; thirdly, a mixed seed solution is prepared; fourthly, fermentation is carried out; fifthly, concentration isoelectric operation is carried out; sixthly, gourmet powder is prepared; seventhly, a biological agent is prepared; eighthly, biological processing is carried out. The method overcomes the technological defects that the fermentation efficiency of the gourmet powder is not high, and the energy conservation and emission reduction cannot meet the standard.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

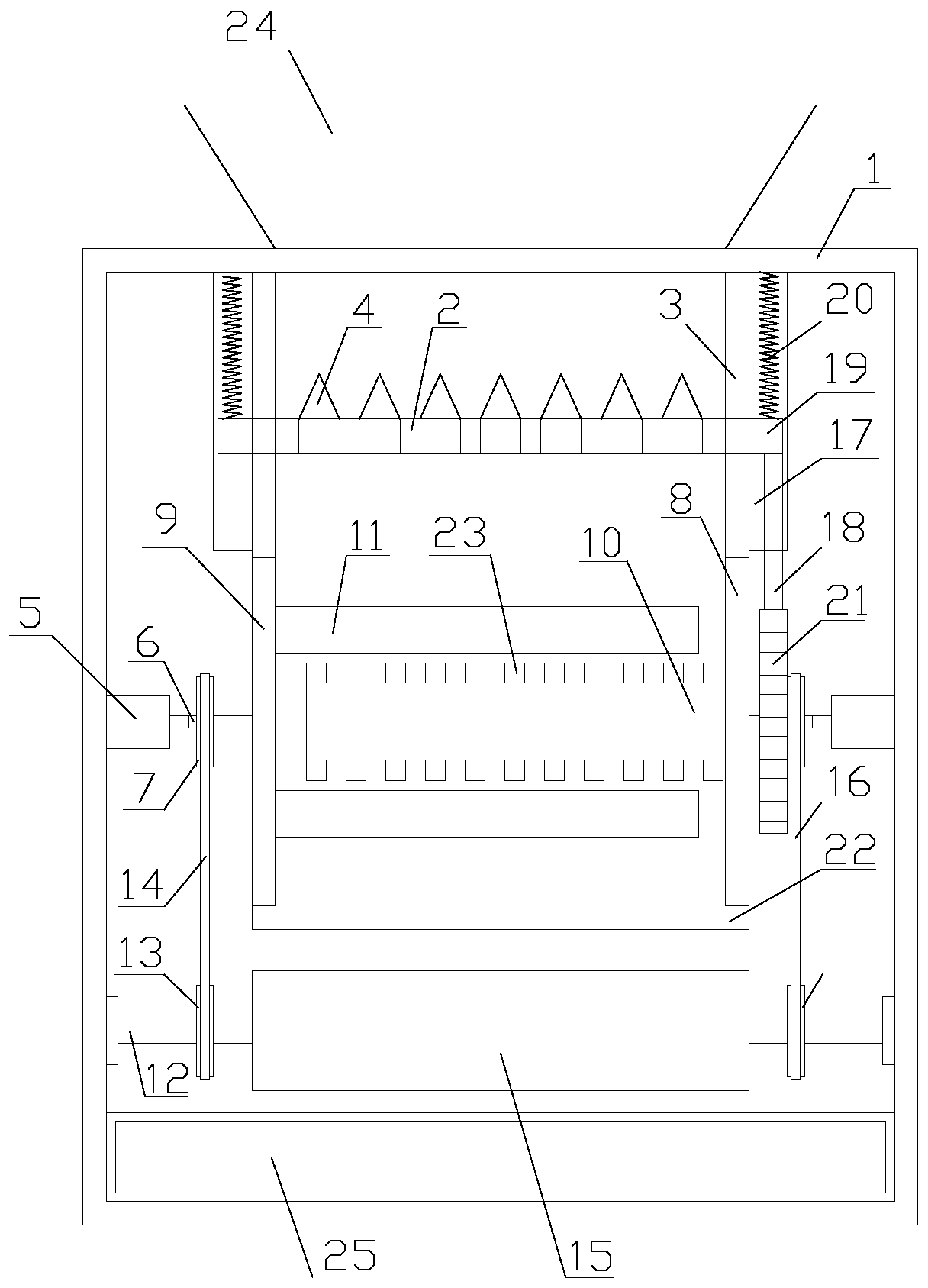

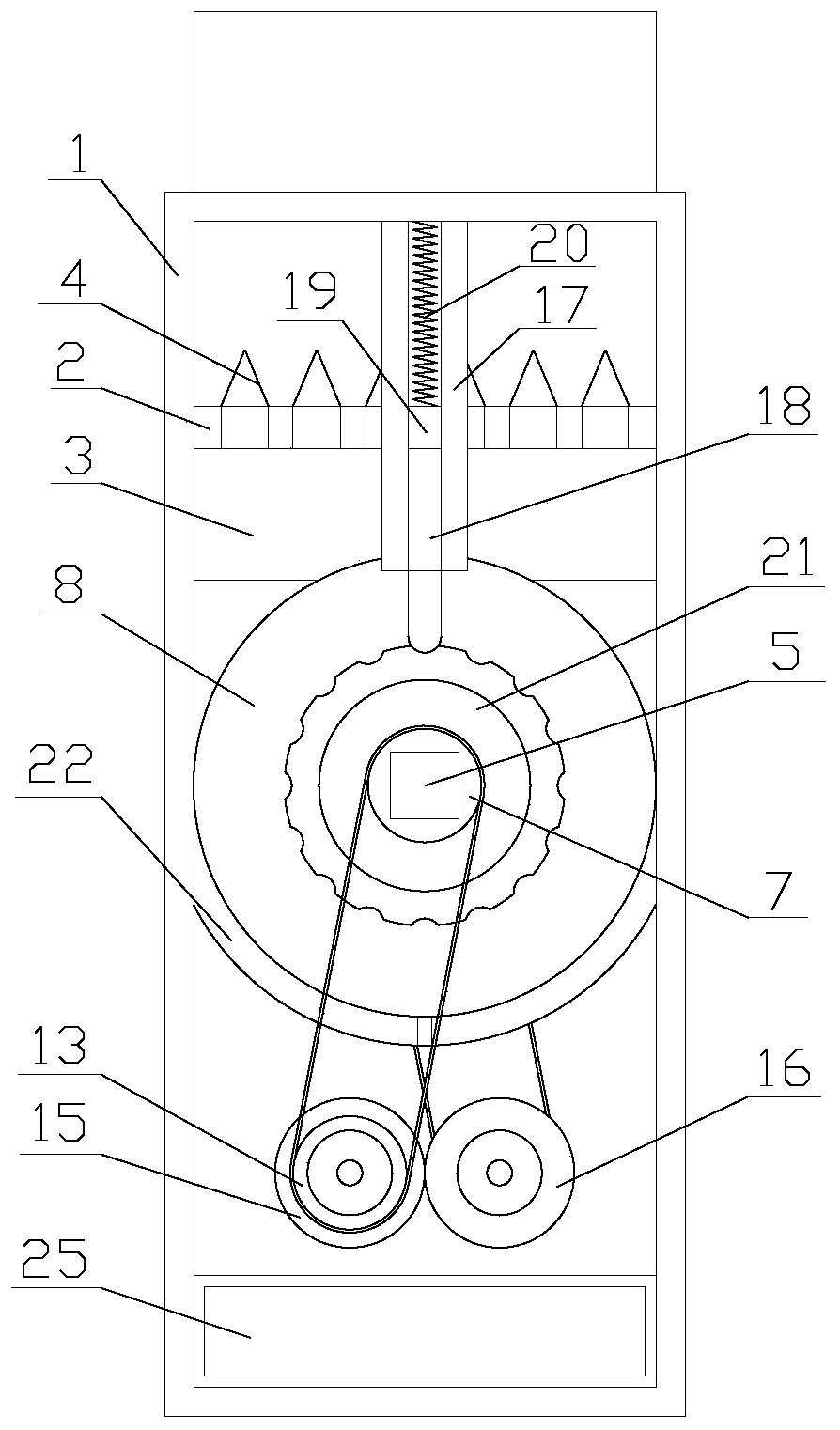

Glass crushing device

ActiveCN111468273AThe glass is crushed fully and evenlySave human effortGlass recyclingGrain treatmentsComposite materialEngineering

The invention relates to a glass crushing device. The glass crushing device comprises a box body, a driving mechanism, a first crushing mechanism, a second crushing mechanism and a third crushing mechanism; the first crushing mechanism, the second crushing mechanism and the third crushing mechanism are sequentially arranged in the box body from top to bottom; and the driving mechanism comprises two driving assemblies. According to the glass crushing device, glass is subjected to primary crushing through the first crushing mechanism, a bottom plate vibrates through a vibration mechanism, and collision between the glass and a crushing head is intensified, so that the glass is crushed more sufficiently; the glass is subjected to secondary grinding through the second crushing mechanism, secondary crushing is achieved, and meanwhile, a stirring roller has the stirring effect, so that the glass is crushed more sufficiently and uniformly; the glass is subjected to three-stage crushing throughthe third crushing mechanism, so that the glass is ground into powder; and large glass blocks are crushed into powder step by step through the three stages of crushing mechanisms, the glass is crushed more sufficiently and uniformly, manpower is saved, and the working efficiency is improved.

Owner:山东正信药用玻璃有限公司

Environment-friendly technique for restoring L-threonine fermentation wastewater

ActiveCN105948400AReduce dosageShorten the timeWater contaminantsTreatment involving filtrationBiotechnologyThreonine

The invention relates to an environment-friendly technique for restoring L-threonine fermentation wastewater. The method uses the combination of a physical method and a biological agent treatment method to perform treatment. The biological agent comprises the following raw materials in parts by volume: 6-7 parts of Arthrobacter, 5-7 parts of pseudomonad, 5-7 parts of Rhodococcus, 4-5 parts of Bacillus amyloliquefaciens, 4-5 parts of Clostridium and 3-4 parts of Scenedesmus obliquus. The biological agent contains multiple microbes with favorable degradability for nondegradable pollutants; the reasonable combination of the strains has favorable degradation effects; and thus, the biological agent has wide application prospects.

Owner:内蒙古阜丰生物科技有限公司

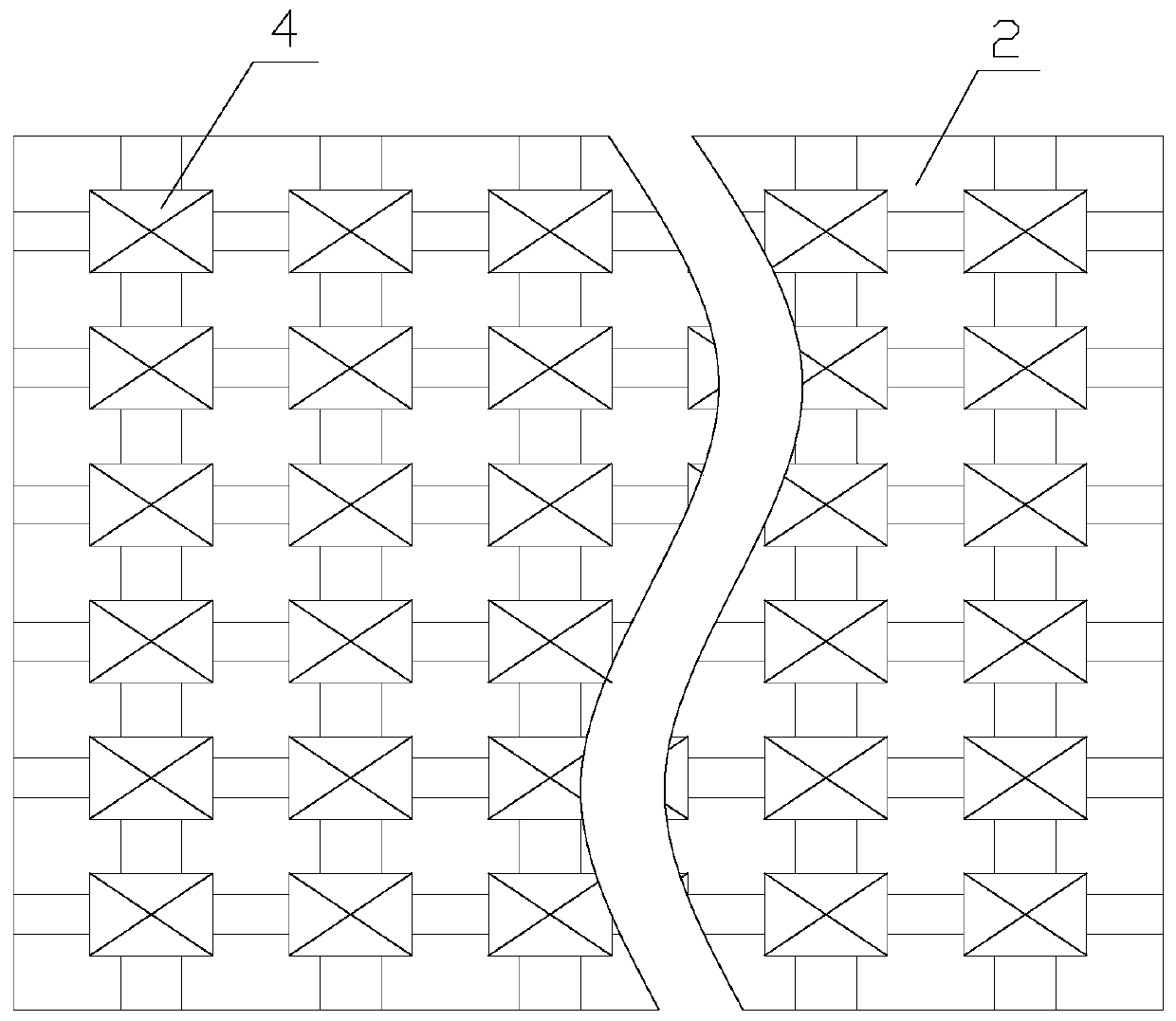

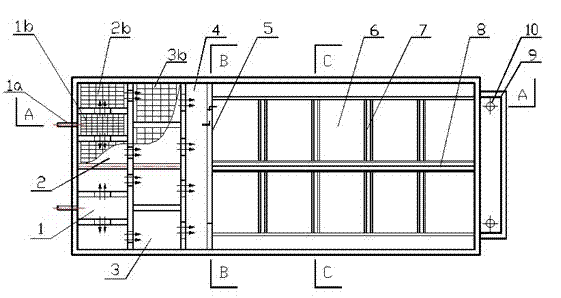

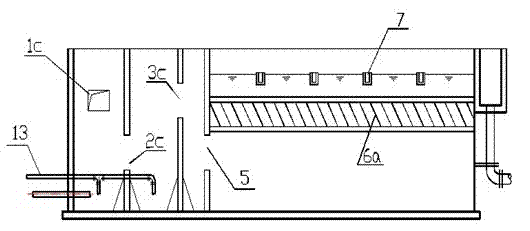

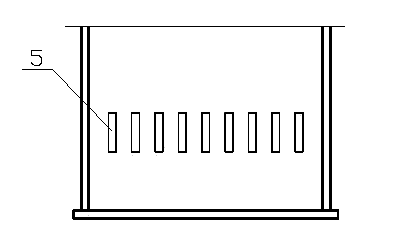

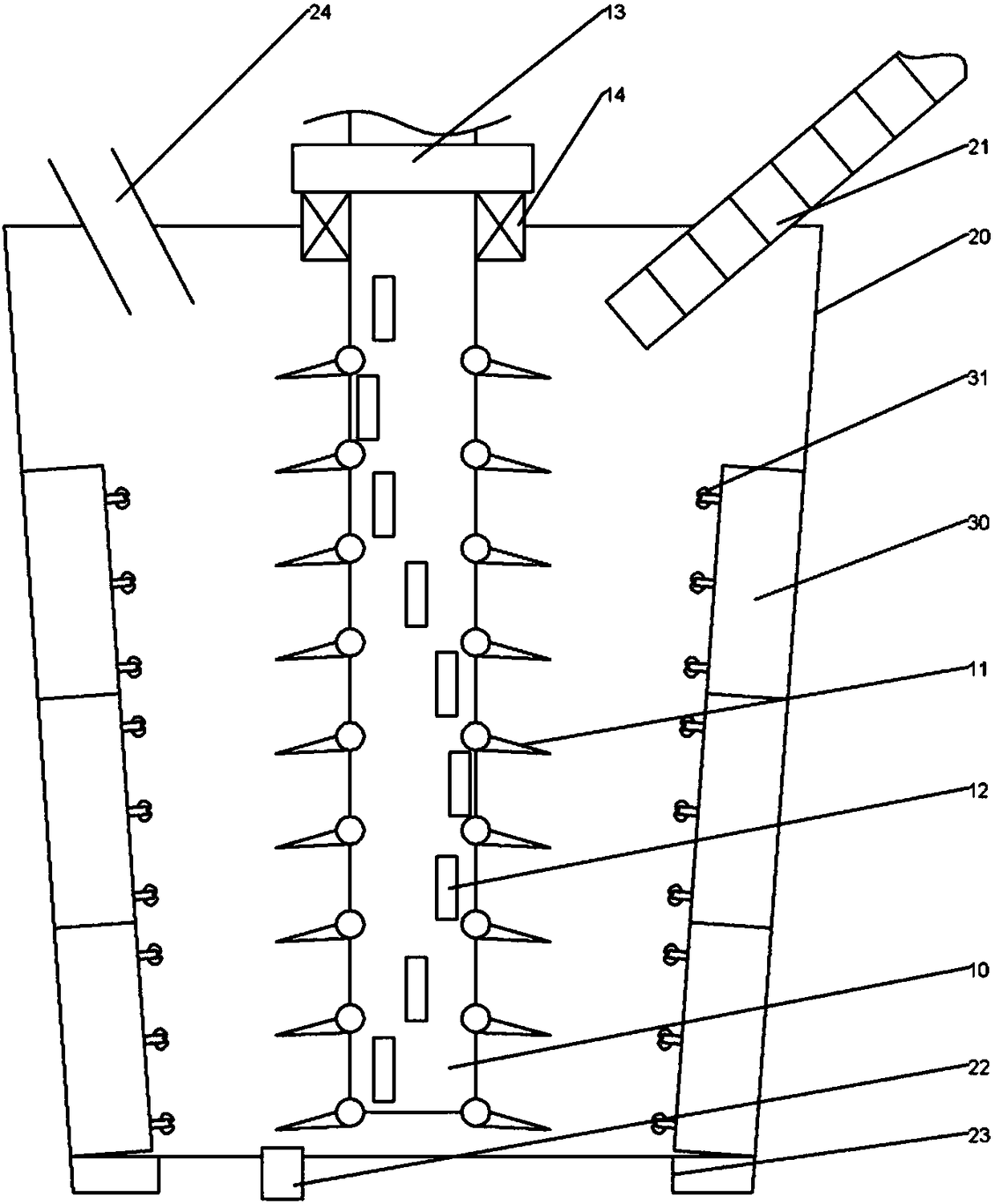

Gridding reaction inclined tube settling pond

InactiveCN102755767AEasy to processGood flocculation effectSettling tanks feed/dischargeSedimentation settling tanksFlocculationEngineering

The invention discloses a gridding reaction inclined tube settling pond. The gridding reaction inclined tube settling pond comprises a gridding reaction pond and an inclined tube settling pond which is communicated with the gridding reaction pond through a water distribution gallery, wherein the gridding reaction pond is composed of a first-level vertical shaft and a second-level vertical shaft which is communicated with first-level vertical shaft, and the vertical shafts are provided with a network in a gradient manner. The gridding reaction pond provided by the invention has the advantages that the construction cost is low, the gridding process is convenient, the flocculation reaction effect is good, different energy requirements of each stage of a flocculation process are meet, the gridding reaction pond and the inclined tube settling pond form a whole, the flocculation setting speed is accelerated in a water treating process, the time cost and the manufacturing cost are saved, and water yield is improved by one third. The gridding reaction inclined tube settling pond can be used for improving the quality of an old factory.

Owner:POWERCHINA ZHONGNAN ENG +1

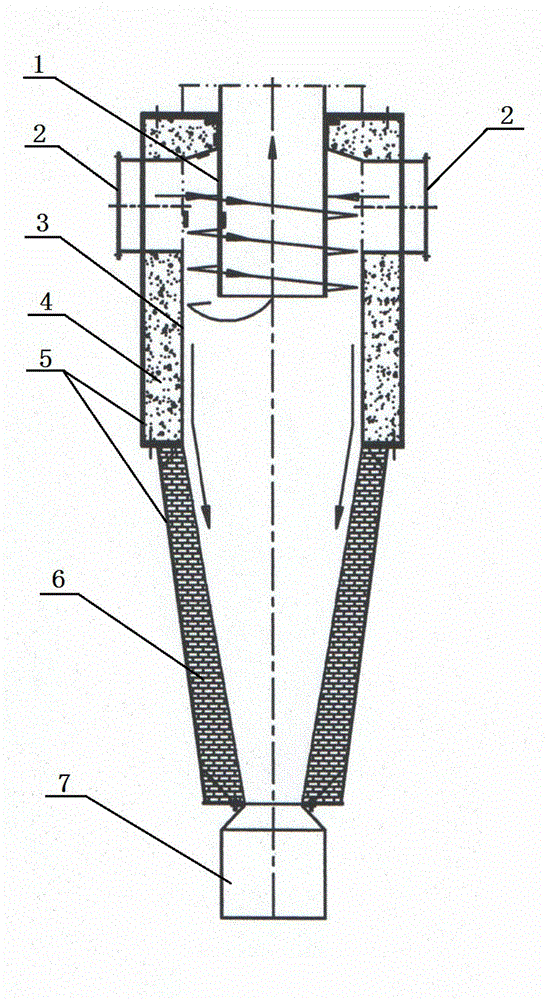

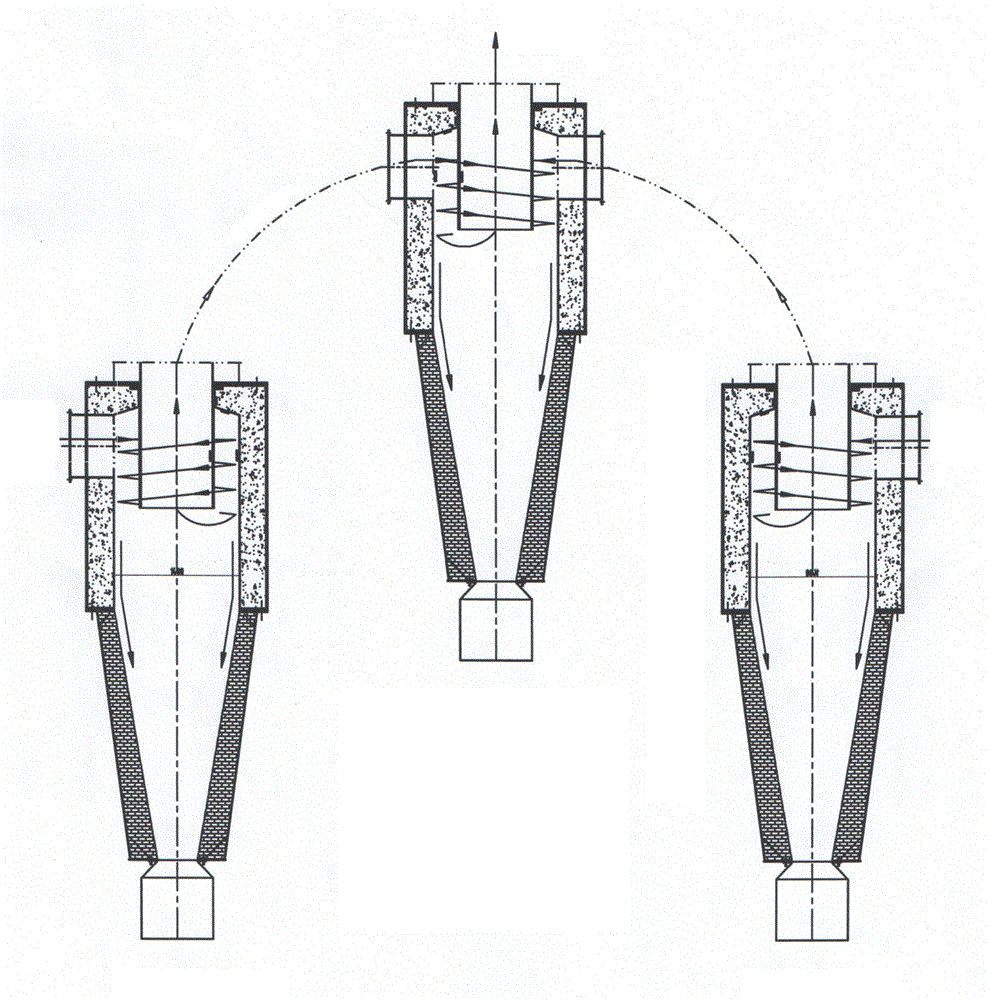

High-temperature cyclone secondary deduster

InactiveCN102872656AIncrease the flue gas velocityReduce pollutionDispersed particle separationCentral cylinderSmoke

The invention relates to a high-temperature cyclone secondary deduster which comprises a cylinder body made of high-temperature-resistant materials. The opening end of the cylinder body is downward, an opening is arranged at the central position of the sealing end at the upper end of the cylinder body, a central cylinder is connected at the central position in sealing mode, and the lower end of the central cylinder extends into the cylinder body. A wall body in a cone cylinder shape is connected at the position below the opening end of the cylinder body, the diameter of the opening position at the upper end is identical to the internal diameter of the opening end of the cylinder body, the diameter of the opening position at the upper end of the wall body is larger than that of the opening position at the lower end of the wall body, and an ash collection cylinder is connected at the opening position at the lower end of the wall body. The wall body is formed by fire-resisting bricks in piling mode. The high-temperature cyclone secondary deduster is characterized in that a smoke inlet is respectively arranged at the radial opposite positions on the section of the lateral wall of the cylinder body corresponding to the central cylinder. The two smoke inlets of the secondary deduster can be simultaneously connected with two smoke outlets of a primary deduster so that flow speed of smoke entering an inner cavity of the secondary deduster is increased, fine harmful material particles in high-temperature smoke are further removed, and pollution to the environment caused by exhausted smoke can be effectively reduced.

Owner:无锡多灵环保工程设备有限公司

Novel concentrating and continuous isoelectric extraction technology for glutamic acid

InactiveCN105039487AReduce consumptionLow costOrganic compound preparationMicroorganism based processesFood technologyWastewater

The invention belongs to the technical field of food, and discloses a novel concentrating and continuous isoelectric extraction technology for glutamic acid. The technology comprises the following steps of 1 mixed seed liquid preparing; 2 glutamic acid preparing through fermentation; 3 concentrating and continuous isoelectric focusing; 4 waste liquid treating. According to the technology, the fermentation efficiency can be improved, waste water can be effectively treated, environmental protection can be achieved, and pollution does not exist.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

An environmentally friendly process for repairing l-threonine fermentation wastewater

ActiveCN105948400BReduce dosageShorten the timeWater contaminantsTreatment involving filtrationBiologyScenedesmus obliquus

The invention relates to an environment-friendly technique for restoring L-threonine fermentation wastewater. The method uses the combination of a physical method and a biological agent treatment method to perform treatment. The biological agent comprises the following raw materials in parts by volume: 6-7 parts of Arthrobacter, 5-7 parts of pseudomonad, 5-7 parts of Rhodococcus, 4-5 parts of Bacillus amyloliquefaciens, 4-5 parts of Clostridium and 3-4 parts of Scenedesmus obliquus. The biological agent contains multiple microbes with favorable degradability for nondegradable pollutants; the reasonable combination of the strains has favorable degradation effects; and thus, the biological agent has wide application prospects.

Owner:内蒙古阜丰生物科技有限公司

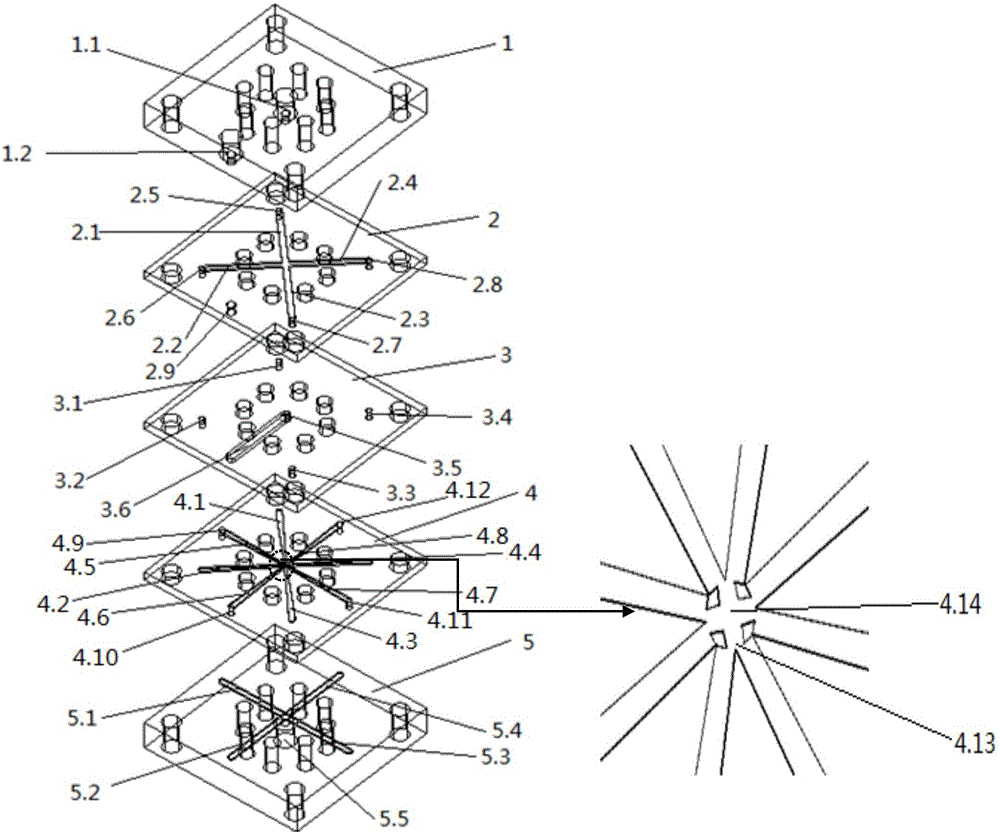

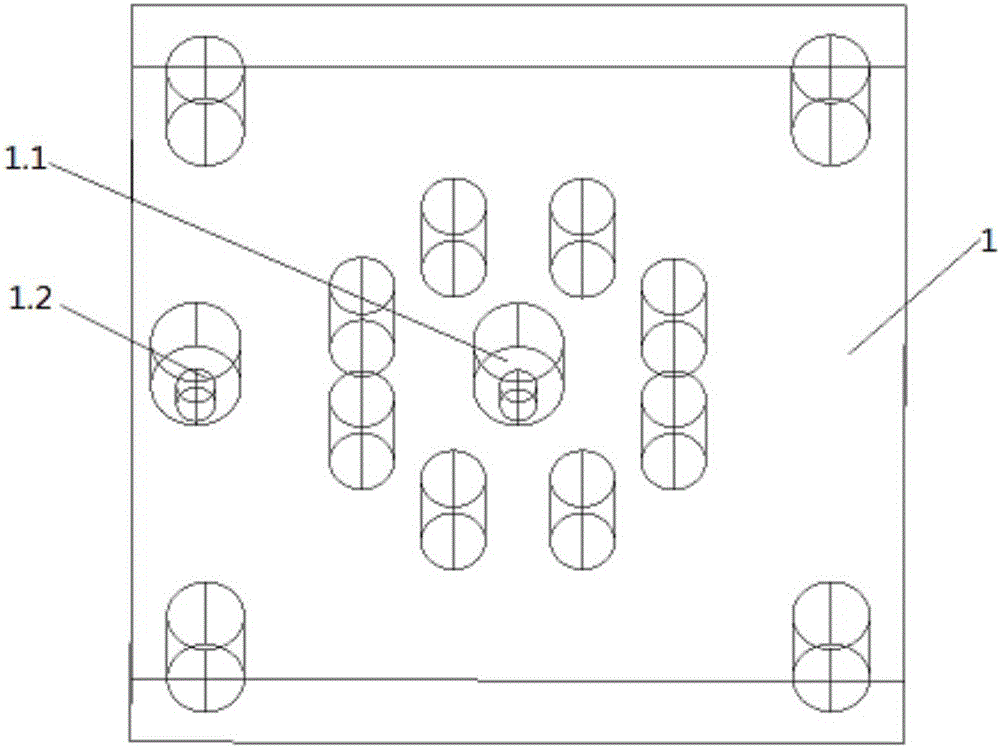

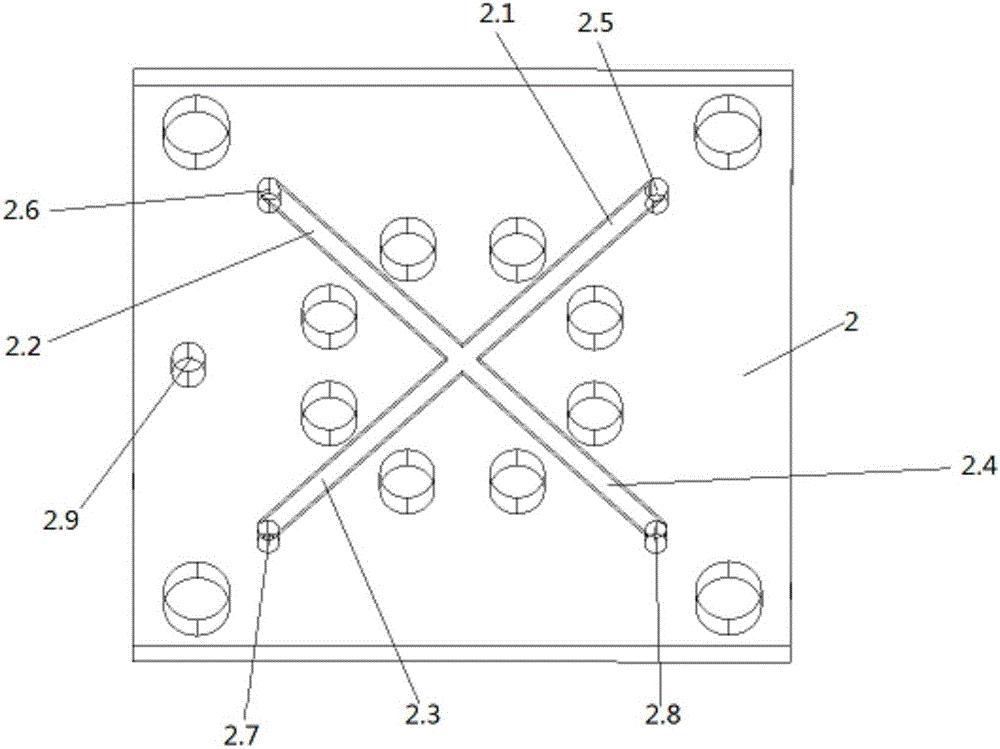

Fully-dispersing passive-type multistage focusing micromixer, and mixing method and application thereof

The invention provides a fully-dispersing passive-type multistage focusing micromixer. The fully-dispersing passive-type multistage focusing micromixer comprises plates No.1 to No.5; the number of multiple stages is n which is more than or equal to 2; the plate No.4 is correspondingly provided with dispersing channels with a number of 2n + 1; the plate No.2 and the plate No.5 are respectively provided with channels with a number of 2n; the plate No.1 is provided with first feeding holes and discharge holes; the plate No.2 is also provided with circulation holes with a number of 2n and circulation holes A; the plate No.3 is also provided with circulation holes with a number of 2n, circulation outlet holes and discharge channels; the plate No.4 is also provided with circulation holes with a number of 2n; the plates No.1 to No.5 are fixedly connected by mutually fitting closely; mixing zones with a multistage number of n are arranged at the central position of the plate No.4, wherein each stage is composed of a plurality of wedge-shaped obstacles; the number of the wedge-shaped obstacles of a first-stage mixing zone is 2n + 1; the number of the wedge-shaped obstacles is stage-by-stage reduced to the mixing zone of n - 1; and when a fluid flows through every stage of the mixing zones, the fluid can generate horizontal laminar shear action due to the presence of the wedge-shaped obstacles, and a chaotic phenomenon is generated in the obstacle zones, so the process of mixing is strengthened.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Demulsification, dehydration and separation method of emulsion

ActiveCN113182086AReduce turbulence intensityImprove coalescenceReversed direction vortexEmulsionAqueous droplet

The invention relates to a demulsification, dehydration and separation method for emulsion. A hydrocyclone comprises a rotational flow chamber and an underflow pipe, the closed end of the rotational flow chamber is connected with an inlet pipe and an overflow pipe, the inlet pipe is tangent to and communicates with the circumferential inner wall of the rotational flow chamber, the overflow pipe penetrates through the closed end of the rotational flow chamber in an insulated mode to communicate with the interior of the rotational flow chamber, the other end of the rotational flow chamber communicates with the underflow pipe through a smooth transition pipe section, and both the rotational flow chamber and the overflow pipe are conductive. The method comprises the following steps that firstly, the emulsion is pretreated; then the overflow pipe faces upwards and is electrically connected with the positive electrode of a high-voltage pulse power supply, the rotational flow chamber is grounded; and then the pretreated emulsion is continuously input into the rotational flow chamber from the inlet pipe. According to the hydrocyclone used in the demulsification and dehydration method, the smooth transition pipe section is adopted for transition between the rotational flow chamber and the underflow pipe, so that the turbulence intensity in the hydrocyclone is reduced, a flow field is promoted to be stable, under the action of an electric field, coalescence of water drops in the emulsion is facilitated, the particle size is increased, and therefore the separation effect and the separation efficiency are improved.

Owner:CHONGQING TECH & BUSINESS UNIV

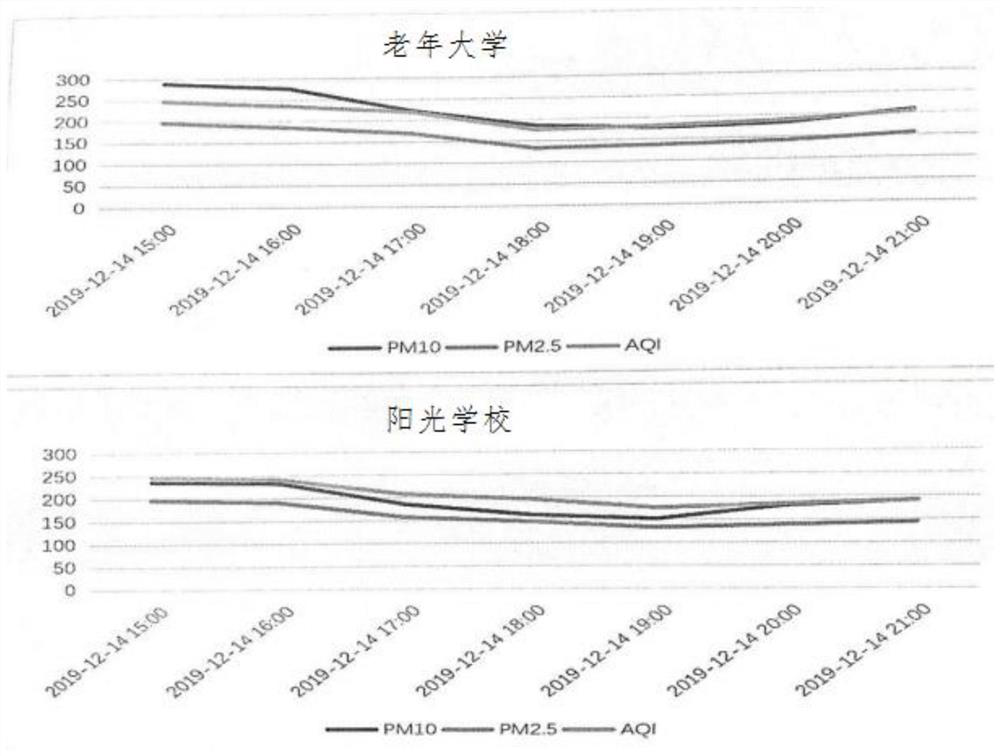

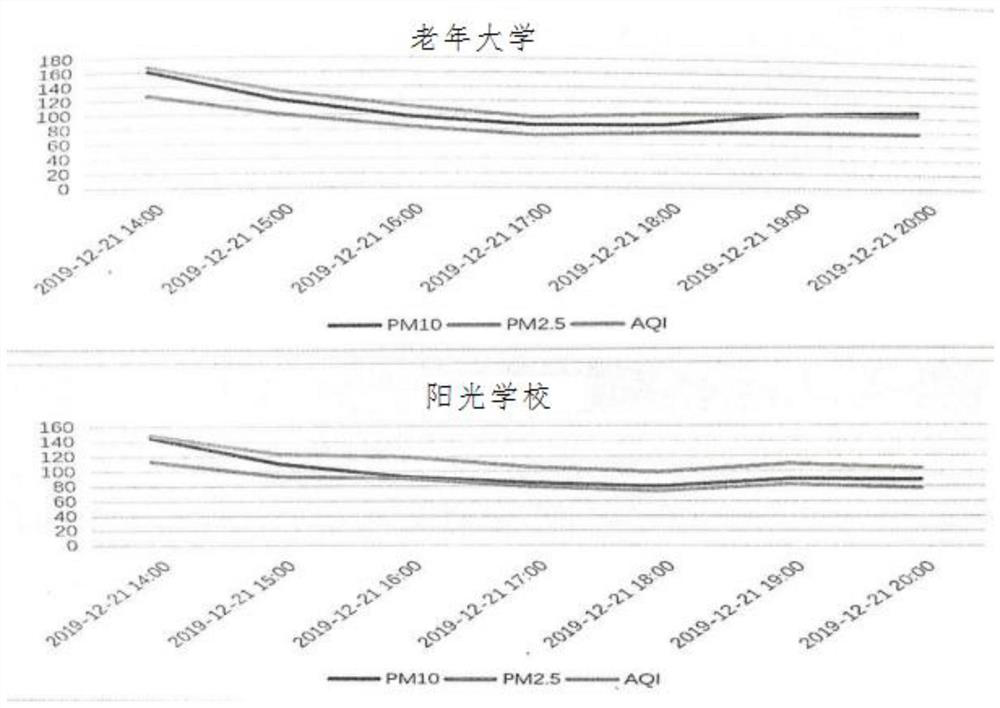

Artificial rainfall agent and preparation method and application thereof

ActiveCN112154839AWithout compromising securityAdsorb soonPhysical/chemical process catalystsWater/sewage treatment by irradiationWater vaporDust particles

The invention relates to the technical field of artificial rainfall, and provides an artificial rainfall agent and a preparation method and application thereof. The artificial rainfall agent comprisessodium chloride particles and titanium dioxide coatings coated on the surfaces of the sodium chloride particles. The artificial rainfall agent provided by the invention is non-toxic and harmless, hasstrong water vapor adsorption capacity, can improve the artificial rainfall efficiency and rainfall capacity, and can be used as condensation nucleus to continuously increase water drops and ice crystals in the cloud and reduce the water drops and ice crystals into rain when being scattered in the cloud layer. In the rainfall process, raindrops enable tiny dust particles and the like to fall ontothe ground, so that the effects of removing haze and reducing PM2.5 are achieved. Besides, titanium dioxide has a photocatalysis effect and can degrade pollutants in air and water, so that the haze removal effect is further improved. When the artificial rainfall agent provided by the invention is applied to artificial precipitation enhancement, hail suppression and haze treatment, an excellent effect can be achieved.

Owner:云尚蓝科技股份有限公司

Semiconductor liquid medicine distribution system with bubble removing function

PendingCN114515522AActs as a passive mixImprove functionalityFlow mixersTransportation and packagingDistribution systemEngineering

The semiconductor liquid medicine distribution system with the bubble removing function comprises a base and a receiving barrel, supporting columns are installed at the four corners of the upper portion of the base, a top valve is installed at the top of the dispensing barrel, a first output pipe is connected to the rear portion of the dispensing barrel, and a second output pipe is connected to the rear portion of the dispensing barrel. One end of the first output pipe is connected with a second output pipe, the exterior of the second output pipe is connected with a third output pipe, one end of the third output pipe is connected with a premixing structure, a discharge pipe is installed outside the receiving barrel, a defoaming device is arranged at the top of the receiving barrel, and an air inlet and exhaust structure is arranged at the top of the top plate. Various medicaments can be passively mixed, and a mixing function is achieved in the distribution process, so that the phenomena of layering and piling of the liquid medicine entering the receiving barrel are avoided, an external device is not needed for mixing, and the functionality of the whole distribution system is improved.

Owner:理纯(上海)洁净技术有限公司

Medicinal material dust removing and drying device for pharmacy department

ActiveCN109612238AIntensified collisionIncrease uncertaintyDispersed particle filtrationTransportation and packagingPharmacyDrive shaft

The invention discloses a medicinal material dust removing and drying device for the pharmacy department and relates to the technical field of medicines. The medicinal material dust removing and drying device comprises a main body. The main body is internally provided with a filter screen and a dust collecting bag. The dust collecting bag is arranged on the outer side of the filter screen. A stirring shaft is arranged inside the filter screen. The outer side of a driving shaft is sleeved with the stirring shaft. The driving shaft is internally provided with a flow channel. The sidewall of thedriving shaft is further provided with through holes communicating with the flow channel in the driving shaft. The upper end of the main body is provided with a feed port. The outer side of the stirring shaft is provided with a plurality of sets of stirring rods. The stirring shaft is provided with open slots corresponding to the through holes of the driving shaft. The outer side of the driving shaft is provided with protrusions matched with grooves of the stirring shaft. The bottom of the driving shaft is provided with a driving mechanism. The end of the driving shaft is provided with a rotary joint. The stirring shaft is further provided with a reciprocating mechanism. The medicinal material dust removing and drying device improves the working efficiency while conducting drying and dustremoval and has the good dust removal and drying effect.

Owner:JILIN BUSINESS & TECH COLLEGE

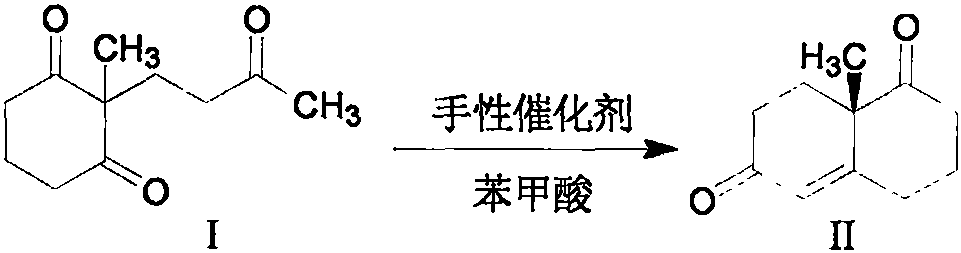

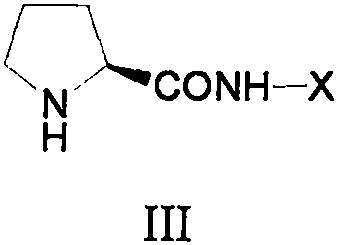

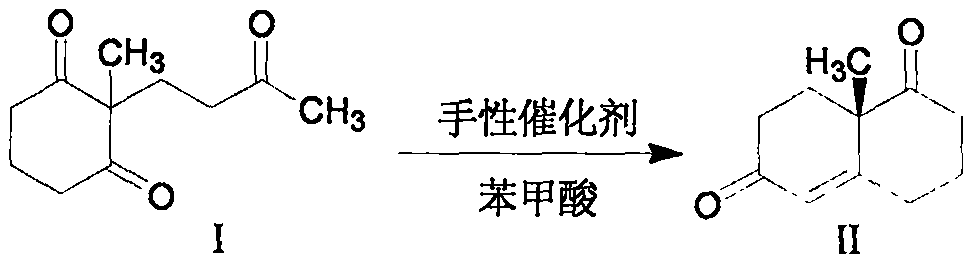

Preparation method of (S)-(+)-3,4,8,8a-tetrahydro-8a-methyl-1,6-(2H,7H)-naphthoquinone

InactiveCN109369364ASimple structure and easy accessLow costOrganic compound preparationOrganic chemistry methodsHydrogenNaphthoquinone

The invention relates to a preparation method of (S)-(+)-3,4,8,8a-tetrahydro-8a-methyl-1,6-(2H,7H)-naphthoquinone. According to the preparation method, an L-proline derivative is used as a chiral catalyst and microwave radiation is introduced into chiral preparation of the (S)-(+)-3,4,8,8a-tetrahydro-8a-methyl-1,6-(2H,7H)-naphthoquinone for the first time through asymmetric Robinson cyclization reaction under conventional conditions or microwave irradiation conditions. Under proper power, an L-prolinamide type catalyst can keep excellent catalysis performance and the catalysis reaction time isshortened; compared with room-temperature stirring conditions, the synthesis efficiency is greatly improved. The molecular collision is aggravated through the microwave radiation and an intermediatecan more easily pass through an energy barrier to form a transition state, so that the reaction time is remarkably shortened, the preparation efficiency of the (S)-(+)-3,4,8,8a-tetrahydro-8a-methyl-1,6-(2H,7H)-naphthoquinone is greatly improved and the synthesis period is shortened. The method is low in cost, simple and rapid, high in yield and good in stereoselectivity.

Owner:中国人民解放军军事科学院防化研究院

Plastic stirring processing device

InactiveCN108262884AImprove cleaning efficiencySpeed up the flowPlastic recyclingEngineeringAirbag deployment

The invention discloses a plastic stirring processing device. The plastic stirring processing device comprises a cleaning tank. A stirring shaft and an airbag mechanism are orderly arranged in the cleaning tank from top to bottom. The stirring shaft is rotatingly connected to the cleaning tank. The stirring shaft is provided with a boss. The cleaning tank is provided with a bearing. The boss presses the bearing so that rotating connection of the stirring shaft and the cleaning tank is realized. The stirring shaft extends to the bottom of the cleaning tank from the top of the cleaning tank. Thestirring shaft is uniformly provided with first stirring blades. The first stirring blades are triangular. The high thickness end of the first stirring blade is fixedly hinged with the first stirringblade. The stirring shaft is provided with a plurality of first permanent magnets. The first permanent magnets on the stirring shaft are spiral. The invention provides the plastic stirring processingdevice for improving cleaning effects on plastic.

Owner:宁波得晴电器科技有限公司

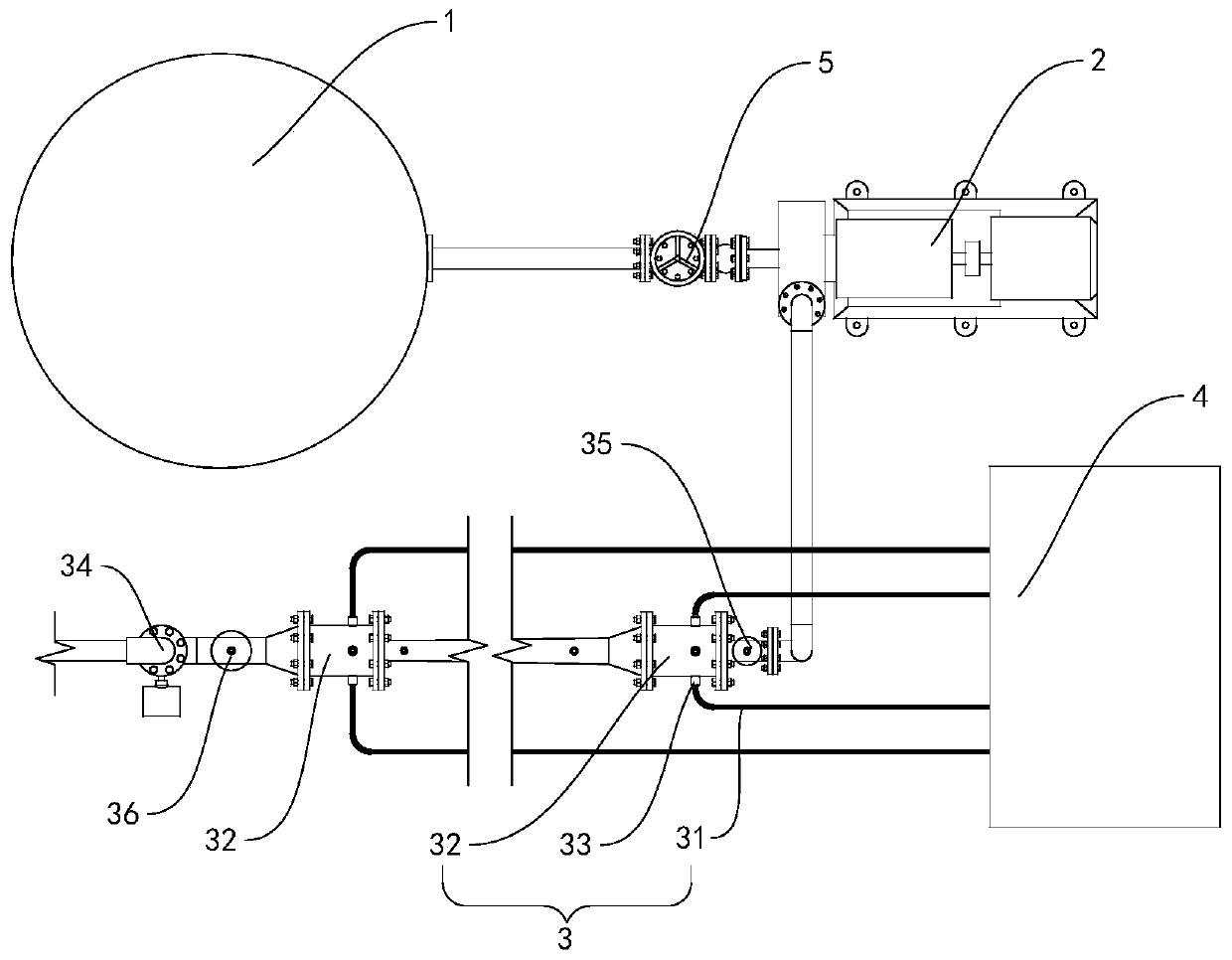

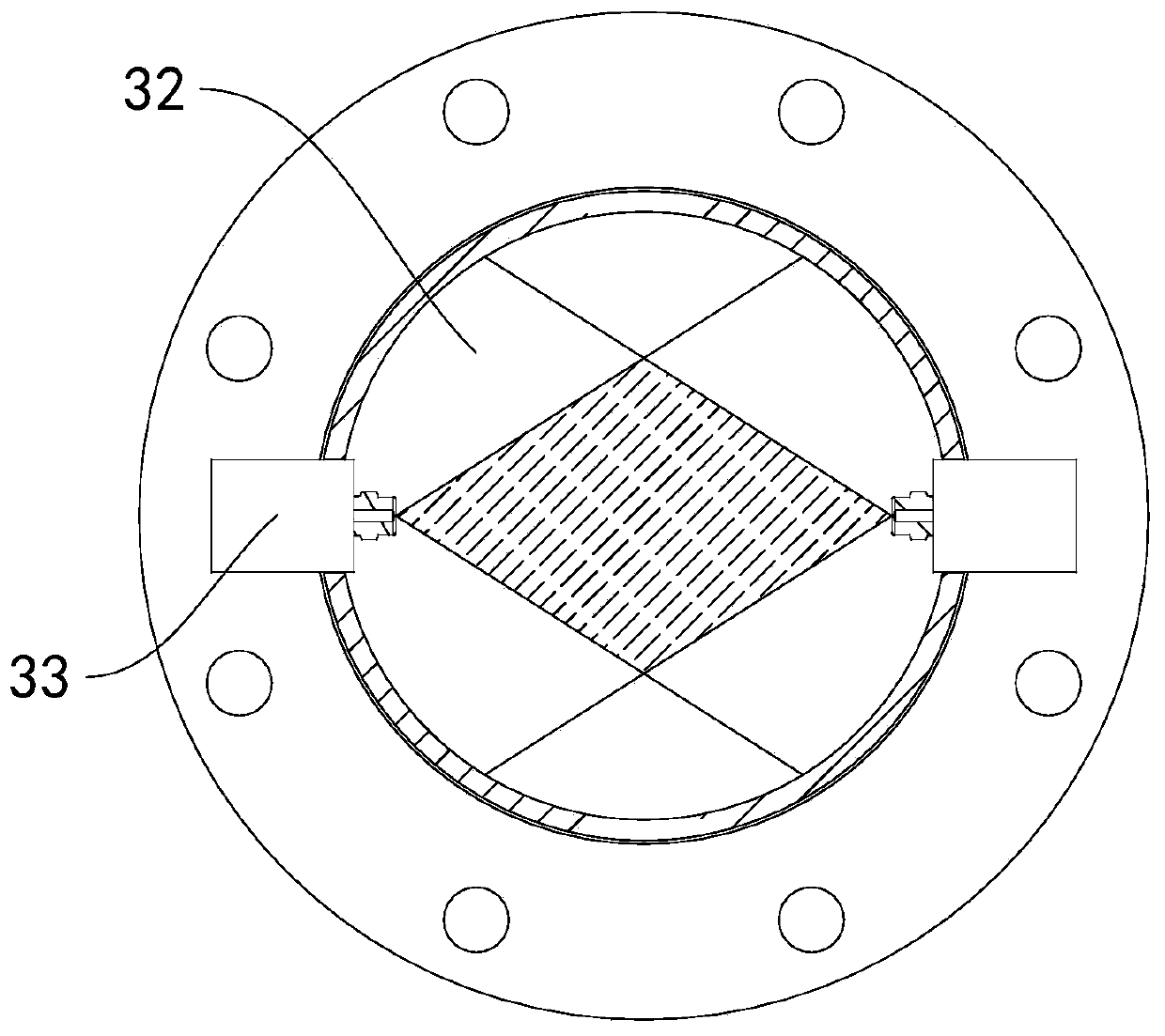

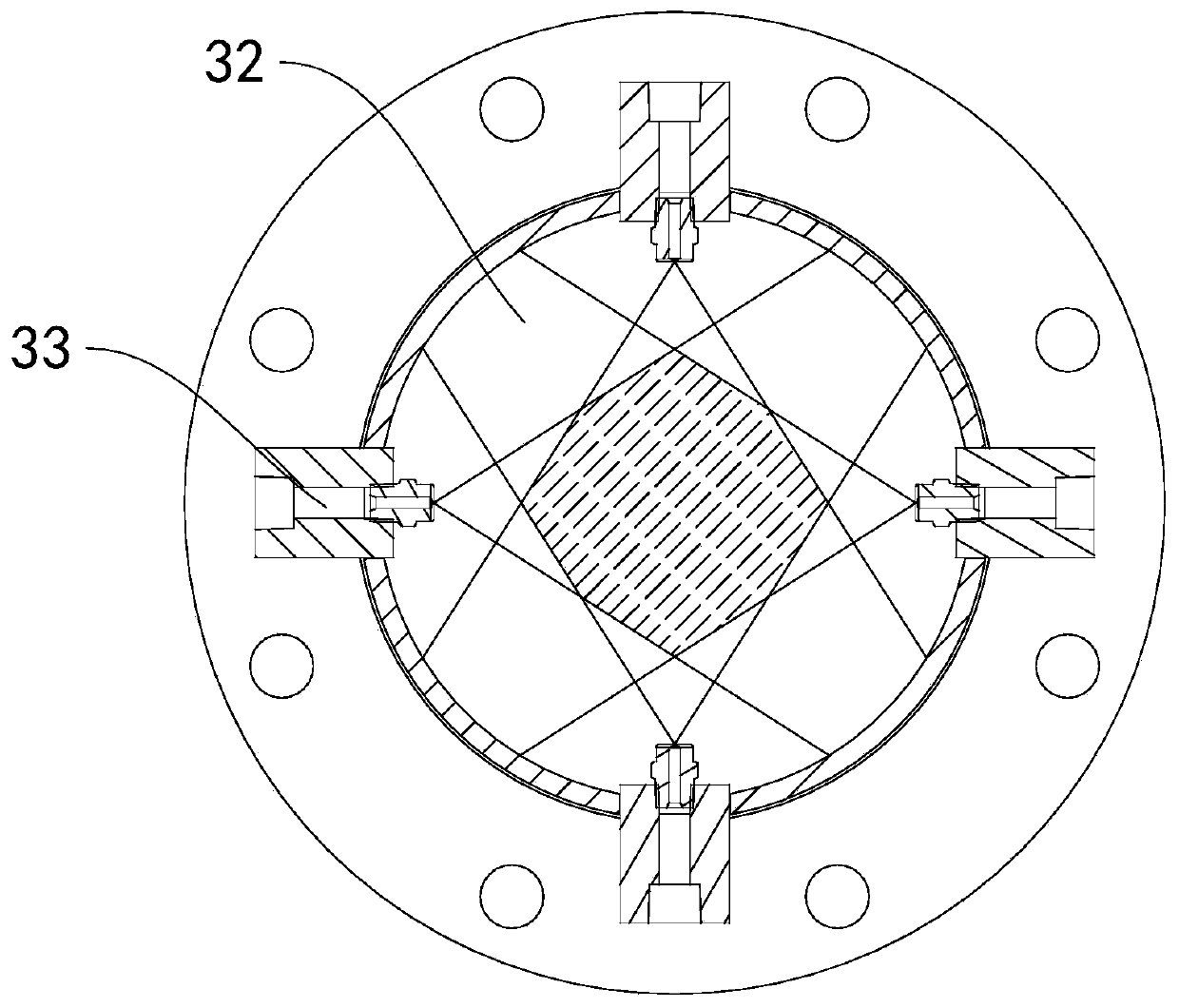

Pipeline type high-pressure spraying elution device and elution method for contaminated soil remediation

The invention discloses a pipeline type high-pressure spraying elution device for contaminated soil remediation, and relates to the technical field of soil remediation equipment. The elution device comprises a slurry tank, a slurry pump, a high-pressure spraying elutriator and a high-pressure power unit; according to the invention, the slurry in the slurry tank is pumped into the high-pressure spraying elution device through the slurry pump; the cleaning liquid is conveyed into each high-pressure pipe and each high-pressure nozzle in a high-pressure state through the high-pressure power unit;the cleaning liquid is then sprayed out at a high pressure of 20-80 Mpa through a high-pressure nozzle; the cleaning liquid passes through a converging section formed by concentrating high-pressure jet flow, and the total hedging force in the section can reach 30-150Mpa, so that the mud is fully mixed, cut and collided, pollutants are promoted to be stripped from soil particles, and the intensified elution of the polluted soil is realized. According to the invention, effective separation of pollutants and soil fine particles can be promoted, the process bottleneck of an existing soil leachingtechnology can be broken through, the environmental safety of a remediation terminal can be improved, and the comprehensive remediation cost can be reduced.

Owner:宝航环境修复有限公司

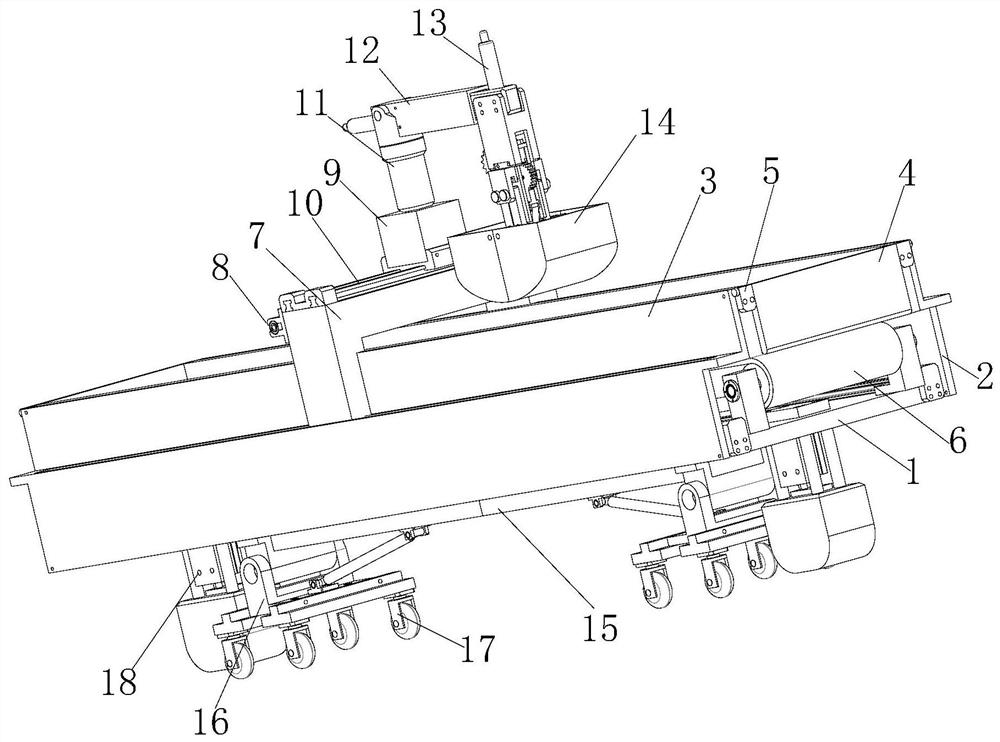

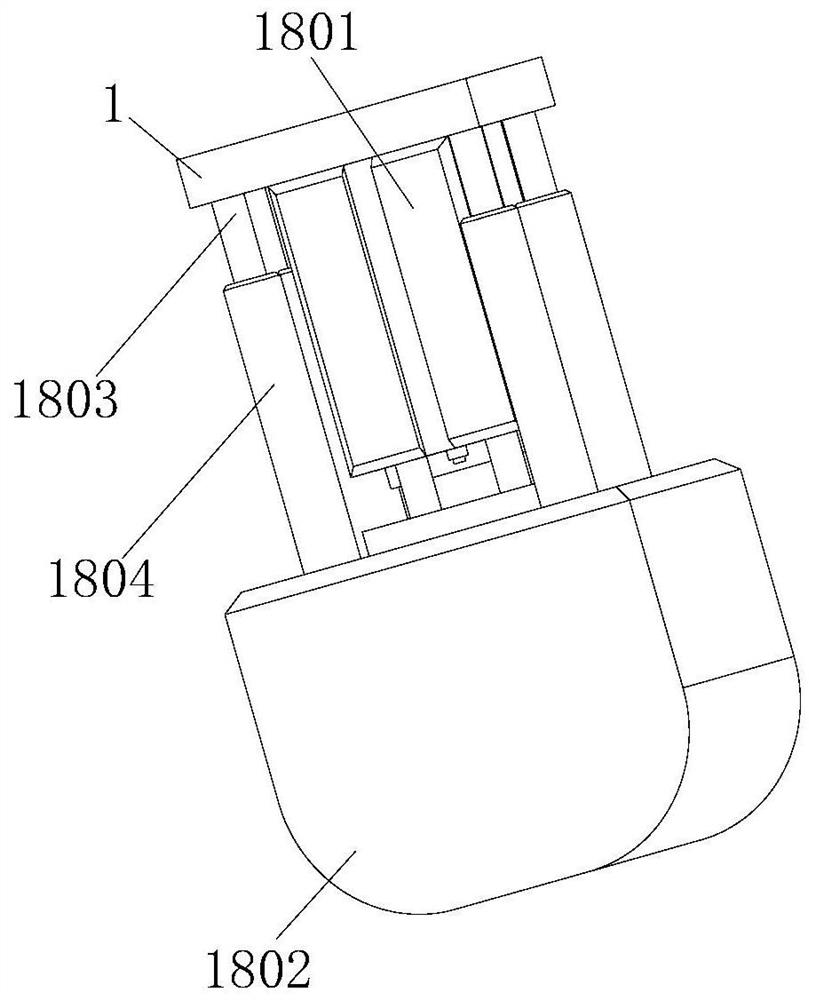

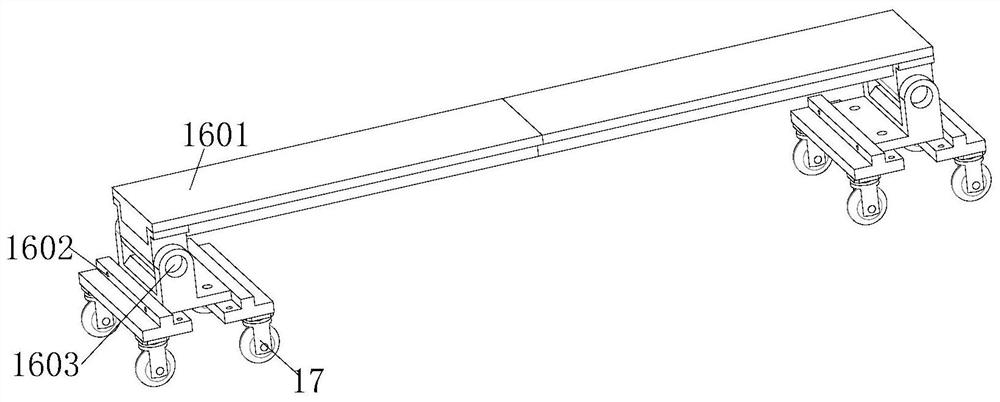

Material transfer device for highway engineering construction

ActiveCN111846809AIntensified shakingImprove filtering effectSievingScreeningHighway engineeringMaterial transfer

The invention relates to the technical field of highway construction, and discloses a material transfer device for highway engineering construction. The material transfer device comprises a first supporting plate, wherein the first supporting plate and second supporting plates connected with the two sides of the first supporting plate form a U-shaped shell; a material transfer box is fixedly arranged at the top of the U-shaped shell; material baffles are connected to the two sides of the material transfer box through bolts; a first limiting assembly enabling the material baffles to rotate around the material transfer box is fixedly arranged between the material baffles and the material transfer box; a first transverse horizontal displacement assembly is fixedly arranged at the top of the first supporting plate; a first sliding seat is fixedly arranged at the output end of the first transverse horizontal displacement assembly; and a longitudinal horizontal displacement assembly is fixedly arranged on one side of the first sliding seat. According to the material transfer device, the problem that a common material transfer device cannot screen coarse aggregates is solved, so that thecoarse aggregates with small particle sizes cannot enter the material transfer box through a material grabbing box, and the phenomenon that the coarse aggregates with the small particle sizes are mixed into concrete is avoided.

Owner:赣州康大高速公路有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com