Material transfer device for highway engineering construction

A technology for engineering construction and transfer devices, which is applied in the directions of transportation and packaging, conveyor objects, filter screens, etc., and can solve problems such as inability to screen coarse aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

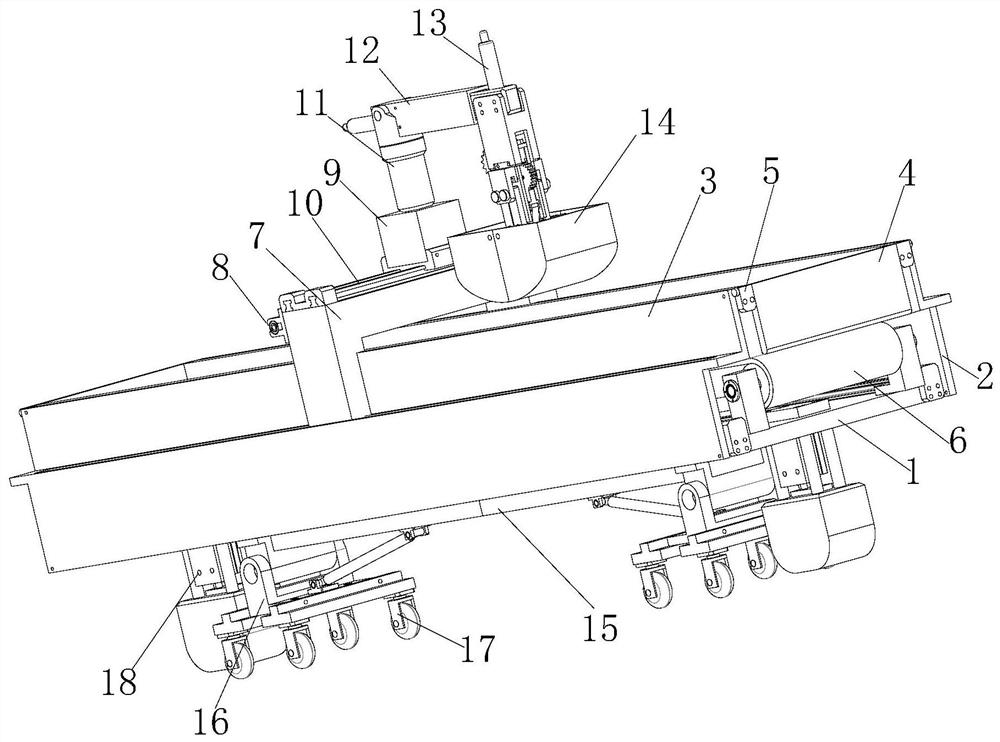

[0041] Such as figure 1 As shown, a material transfer device for highway engineering construction includes a first support plate 1, the second support plate 2 connected to the first support plate 1 and its two sides forms a U-shaped shell, and the top of the U-shaped shell is fixedly provided with a transfer material Both sides of the box 3 and the transfer box 3 are bolt-connected with a baffle plate 4, and a first stop is fixed between the baffle plate 4 and the transfer box 3 to make the baffle plate 4 rotate around the transfer box 3 Assemblies 5, the top of the first support plate 1 is fixedly provided with the first lateral horizontal displacement assembly 6, the output end of the first lateral horizontal displacement assembly 6 is fixedly provided with the first sliding seat 7, and one side of the first sliding seat 7 is fixedly provided There is a longitudinal horizontal displacement assembly 8, the output end of the longitudinal horizontal displacement assembly 8 is f...

Embodiment 2

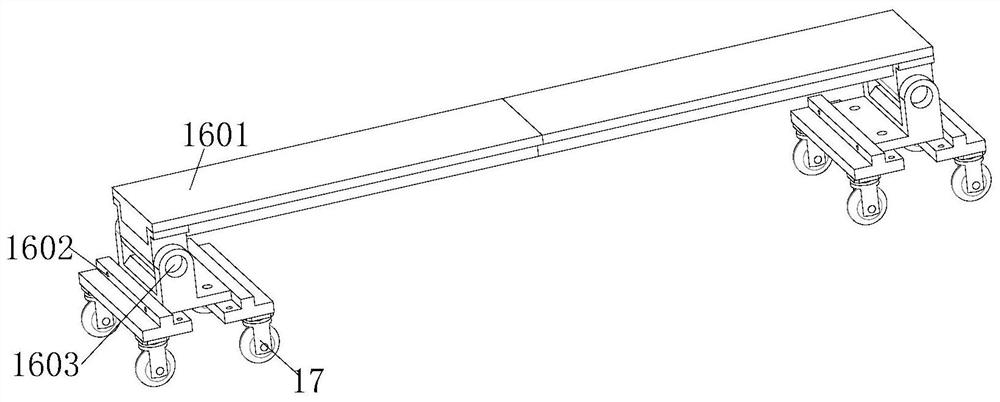

[0043] On the basis of Example 1, such as figure 1 As shown, the number of support assemblies 18 is two, and the two support assemblies 18 are arranged symmetrically with the vertical midline of the base 15 as the axis of symmetry.

Embodiment 3

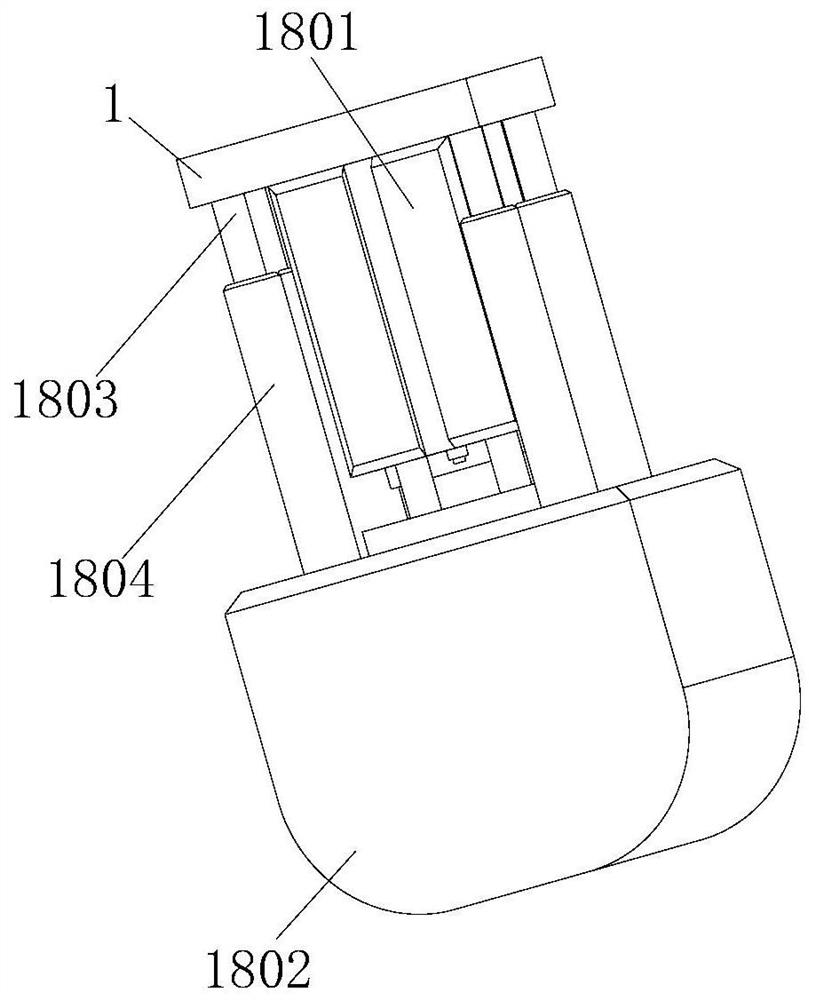

[0045] On the basis of Example 1, such as Figure 1-2 As shown, the support assembly 18 includes a biaxial cylinder 1801 fixedly arranged at the bottom of the first support plate 1, the output end of the biaxial cylinder 1801 is fixedly connected with a third support block 1802, and the top of the third support block 1802 is fixedly provided with a second A limiting rod 1803 , and a limiting cylinder 1804 for limiting the second limiting rod 1803 is movably disposed between the second limiting rod 1803 and the first support plate 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com