Integrated blade transportation frame

A transport frame, integrated technology, applied in the direction of transport and packaging, external frame, container to prevent mechanical damage, etc., can solve the problems of ship heaving, blade damage, lack of integrated bracket to transport blades in batches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

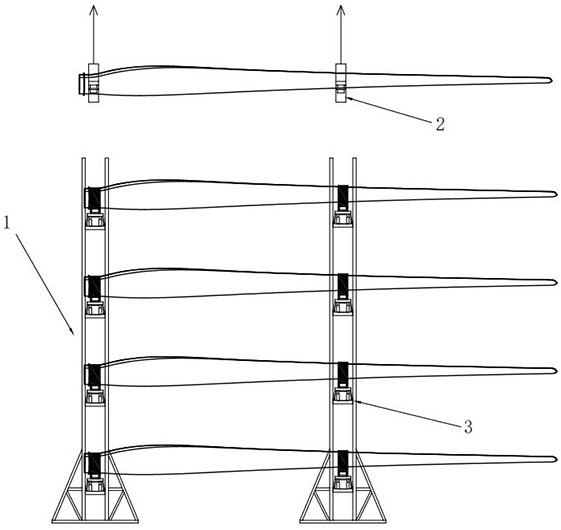

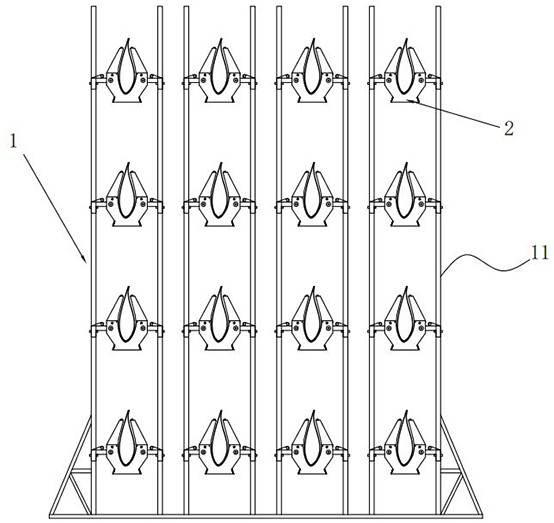

[0034] An integrated blade transport rack such as figure 1 with figure 2 As shown, it includes a pile stabilization platform support 1 and several groups of conveying bases, each blade is placed on / in a group of conveying bases, and is connected to the support 1 through the conveying base;

[0035] Such as figure 2 As shown, the support 1 includes a base and four sets of trusses 11 welded on the base, each set of trusses 11 is provided with four sets of sockets distributed up and down, and each set of sockets is correspondingly plugged with a set of conveying bases to place a blade. 4*4=16 blades can be transported; each group of trusses includes two vertical columns, and the sockets are fixed on the sides of the columns close to each other, so that the transport base avoids the position of the upper socket and connects to the lower socket.

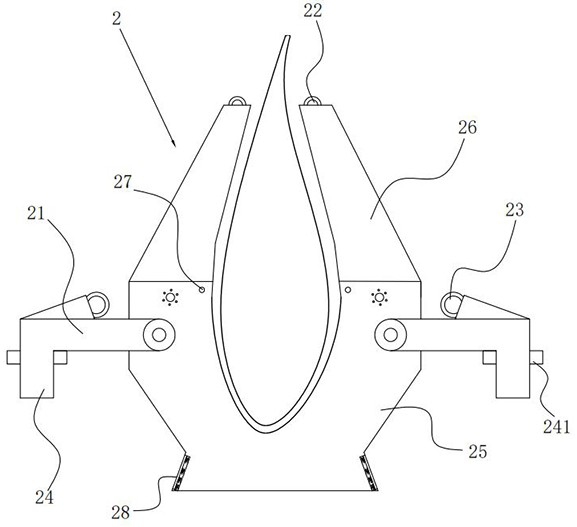

[0036] Among them, such as image 3 with Figure 5 As shown, there are two sets of conveying bases, one is connected to the root o...

Embodiment 2

[0045] This embodiment is roughly the same in structure as Embodiment 1, and the difference mainly lies in:

[0046] In order to avoid rigid collision between the plug 24 and the bracket 1 when the plug 24 is inserted into the socket, as Figure 6 As shown, several groups of buffer seats 3 are also fixed on the bracket 1, the sockets are arranged on the top of the buffer seats 3, and the delivery base is placed on the bracket 1 through the buffer seats 3;

[0047] Specifically, the buffer seat 3 includes a base plate 31, the base plate 31 is fixed on the bracket 1, and two vertical shock absorbers 32 (buffer cylinders) are connected to it, the top of the shock absorber 32 is connected to the base support plate 33, and the socket is opened on the base support. board 33.

[0048] Such as Figure 6 As shown, there are side frames 34 hinged on both sides of the bottom plate 31. The rotational position of the side frame 34 passes through the closed position and the open position....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com