Fixable translation crane for maintenance of equipment in cabin

An in-cabin, fixed technology, used in cranes, load hanging elements, walking bridge cranes, etc., can solve the problems of narrowness, inconvenient installation, and large space occupation, and achieves small space height, convenient installation, and occupation of the engine room. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

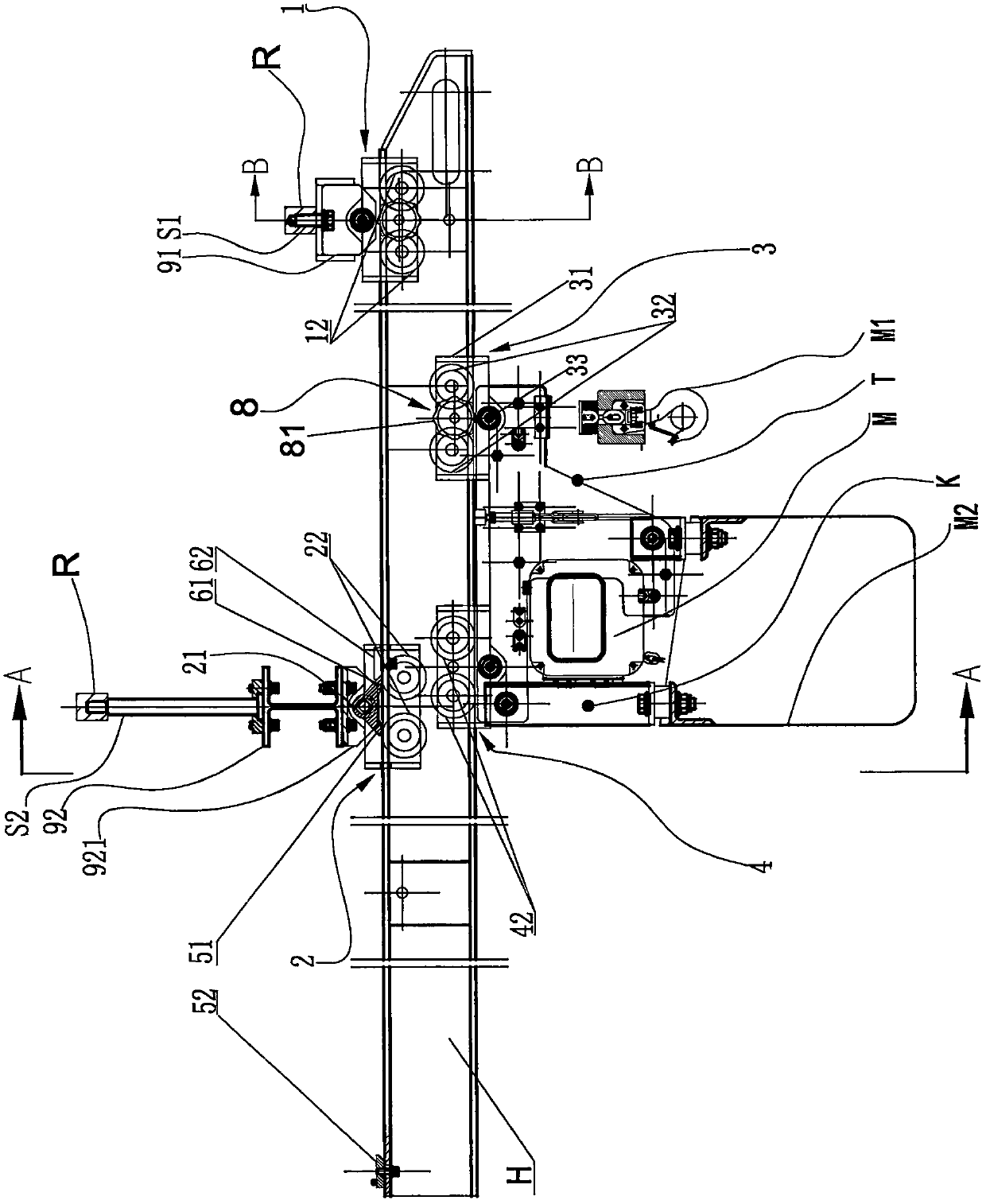

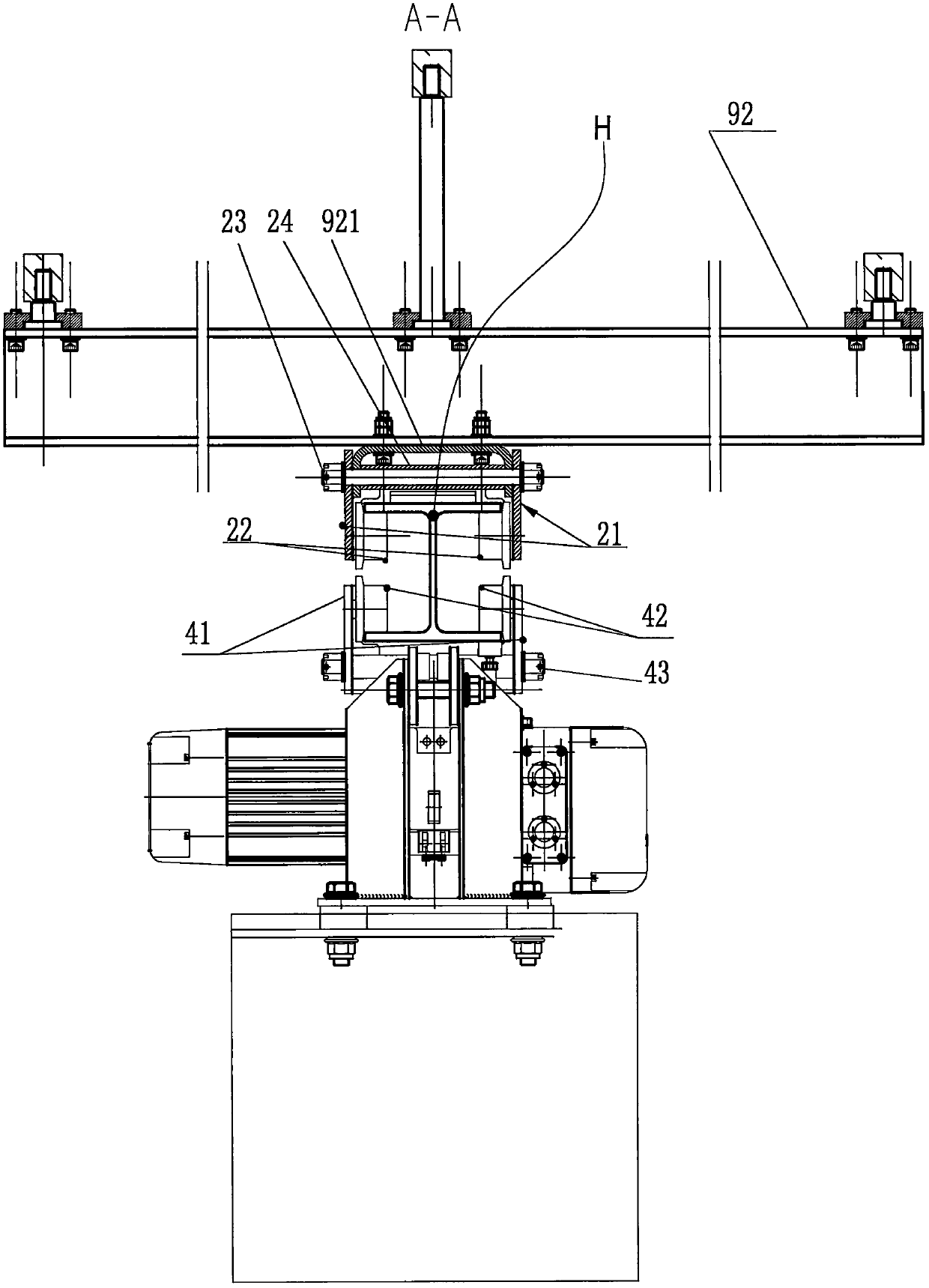

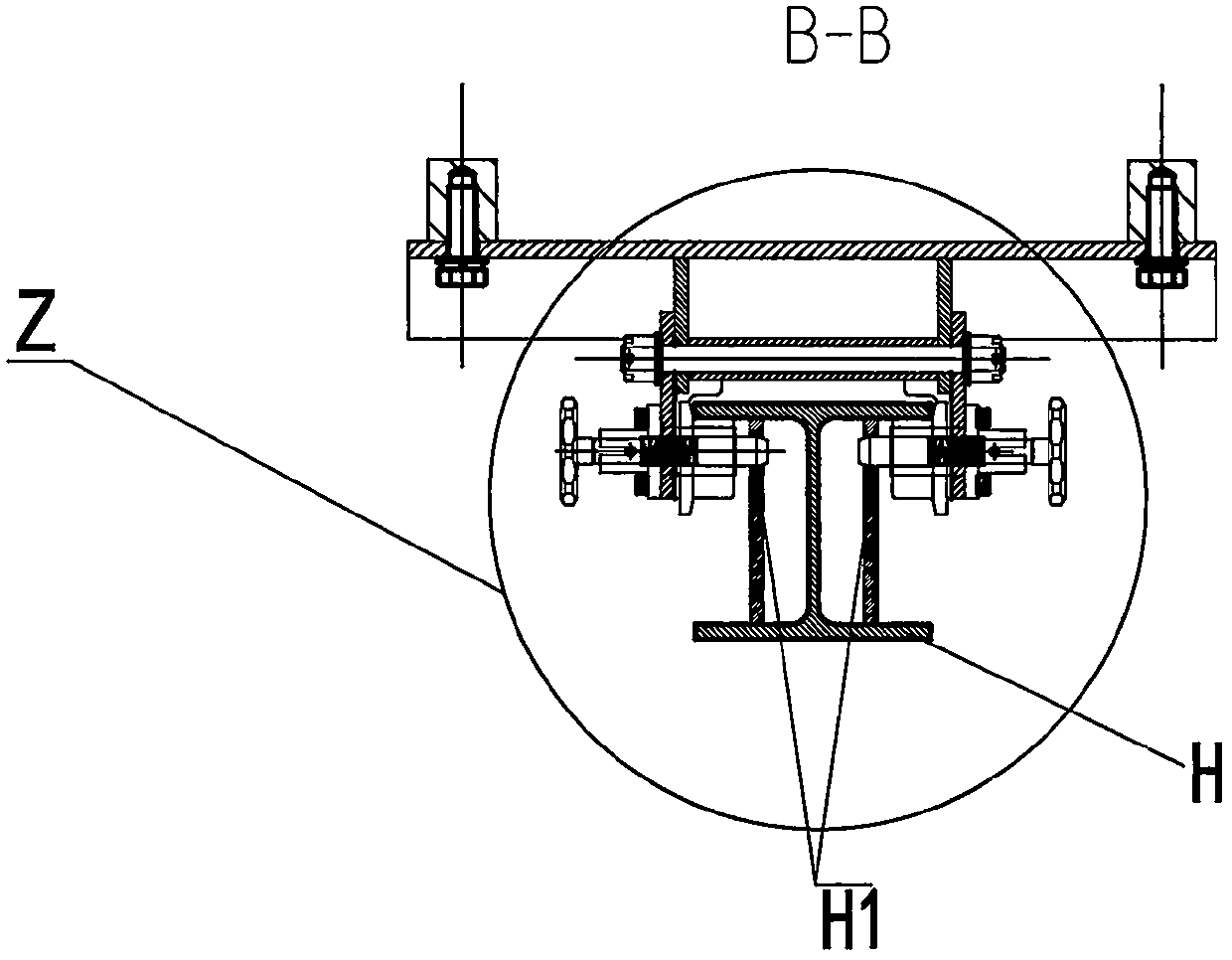

[0020] Fixed translational crane for equipment maintenance in the engine room, including two sets of upper trolley devices fixed under the roof of the engine room R, translation beam H, two sets of lower trolley devices, connecting frame T, chain electric hoisting crane M and storage chain Bag M2, wherein one set of upper trolley device 1 is located adjacent to the relatively low cabin door, the other set of upper trolley device 2 is located behind a set of upper trolley device 1, and the upper wing of the translational beam H is directly suspended and supported on a On the support wheel 12 of the upper trolley device 1 and the support wheel 22 of the other upper trolley device 2, the connecting frame T is located under the translation beam H, and the two sets of lower trolley devices are respectively slidingly fitted on the lower wings of the translation beam H , and a group of lower trolley devices 3 are connected to the front upper part of the connecting frame T, another set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com