High-temperature cyclone secondary deduster

A dust collector and cyclone technology, which is applied in the field of waste incineration devices, can solve problems such as environmental pollution, and achieve the effects of reducing pollution and increasing the flow rate of flue gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

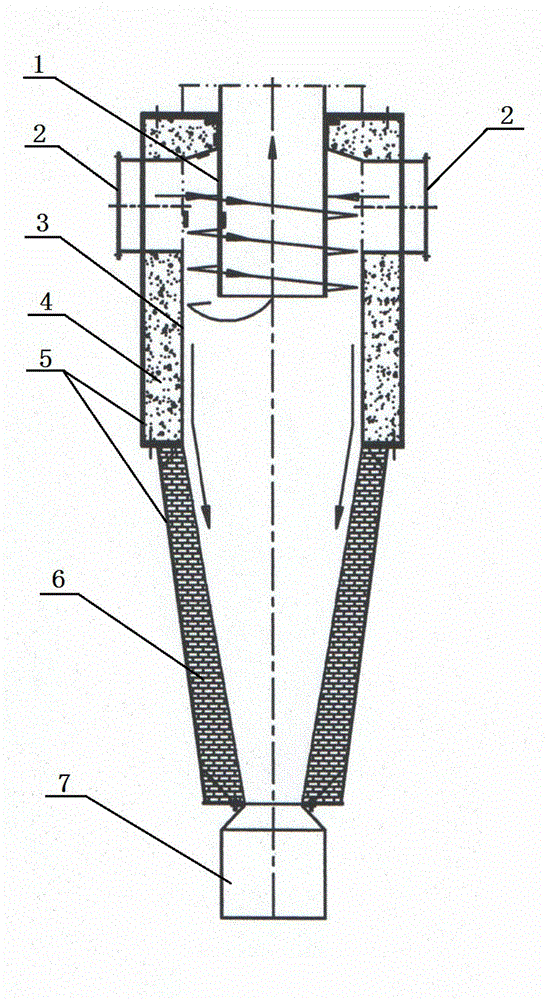

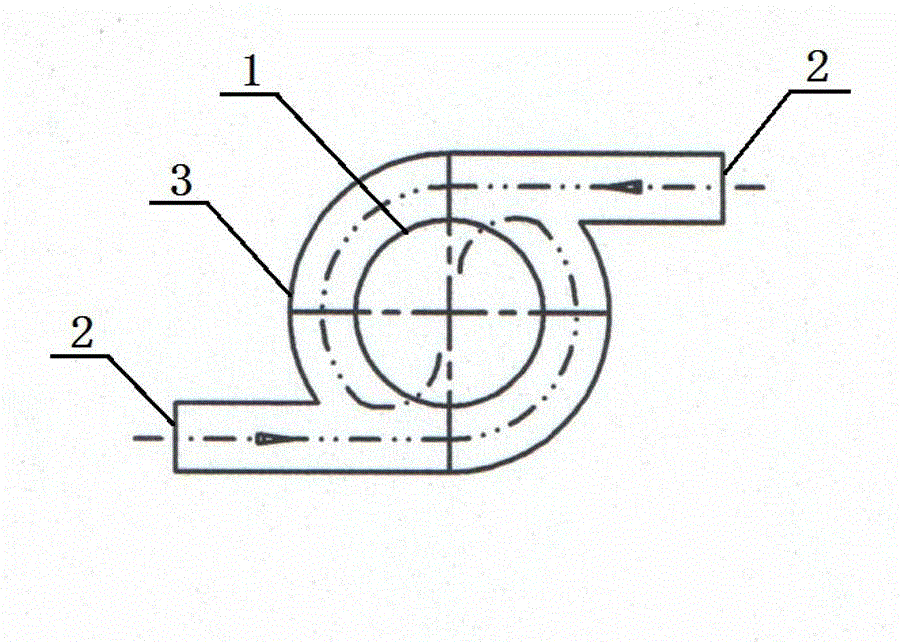

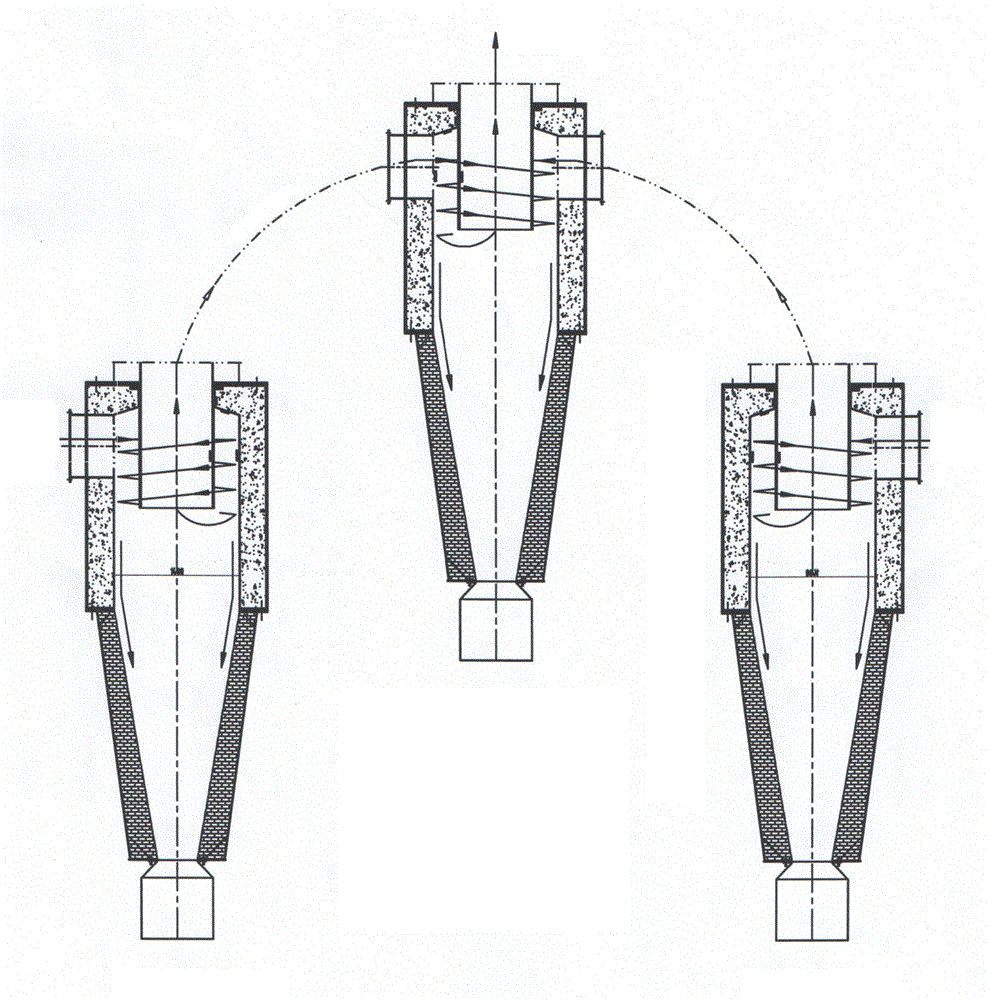

[0015] like figure 1 and figure 2 As shown, the high-temperature cyclone secondary dust collector of the present invention includes a cylinder body 3 made of high-temperature-resistant materials. The open end of the cylinder body 3 faces downwards and is connected with a wall body 6 . The body of wall 6 is in the shape of a conical cylinder, which is made of refractory bricks. The diameter of the upper opening of the wall 6 is equal to the inner diameter of the opening of the cylinder 3, the diameter of the upper opening of the wall 6 is greater than the diameter of the lower opening, and the lower opening of the wall 6 is connected with an ash collection tube 7. There is an opening at the center of the closed end of the upper end of the cylinder 3, and the central cylinder 1 is sealed and connected to the opening. The central cylinder 1 is made of high-temperature-resistant ceramic material, and its lower end extends into the cylinder body 3 , and the central cylinder 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com