Sulfur dioxide flue gas absorption system and method for treating sulfur dioxide flue gas

A sulfur dioxide and absorption system technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of insufficient reaction between flue gas and lime slurry, unsteady exhaust gas concentration, and difficulty in guaranteeing occupational hygiene, etc. Sedimentation and scaling, reducing the scaling in the tower, reducing the effect of the cross-sectional area in the tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

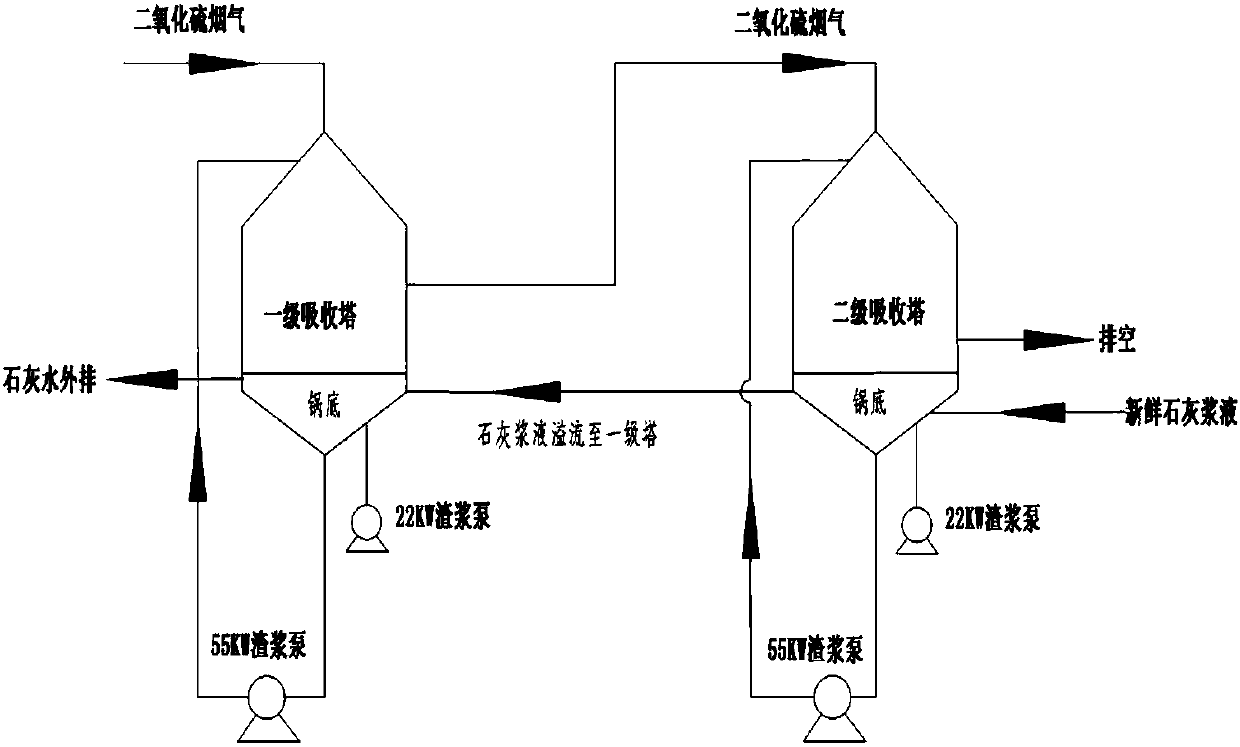

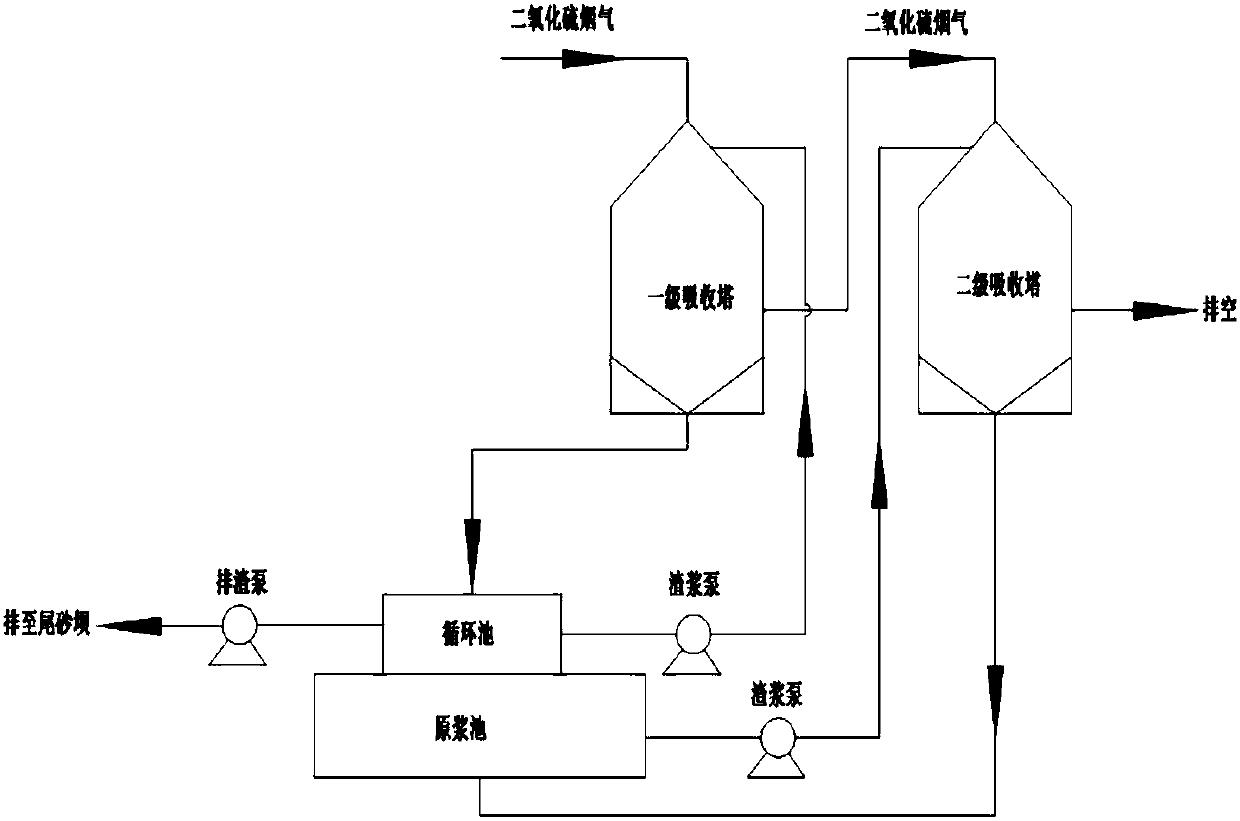

[0028] The fine lime powder is made into lime slurry in the pulping tank (the concentration of CaO is above 80%, the particle size is 200 mesh, and the concentration of lime slurry is controlled at about 7%), and it enters the raw slurry tank by gravity. The lime slurry in the raw slurry tank is pumped into the secondary absorption tower by a 55kw slurry pump for spray absorption. After absorption, it flows back to the raw slurry tank and then overflows into the circulating slurry tank. The lime slurry in the circulating slurry tank is pumped into the primary absorption tower through a 55kw slurry pump, and flows into the circulating slurry tank after being absorbed; absorbing SO 2 The final slurry is discharged through the slag discharge pump and enters the tailings system.

[0029] The slag discharge process is that when the pH value in the circulating lime slurry tank reaches the set value (generally set at about 6), the slag discharge pump is turned on for slag discharge, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com