Electrically controlled polarization beam splitting device with adjustable splitting ratio, and splitting ratio control method

A technology of polarization beam splitting and splitting ratio, which is applied in optics, nonlinear optics, instruments, etc., to achieve the effect of continuous change and precise dynamic adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

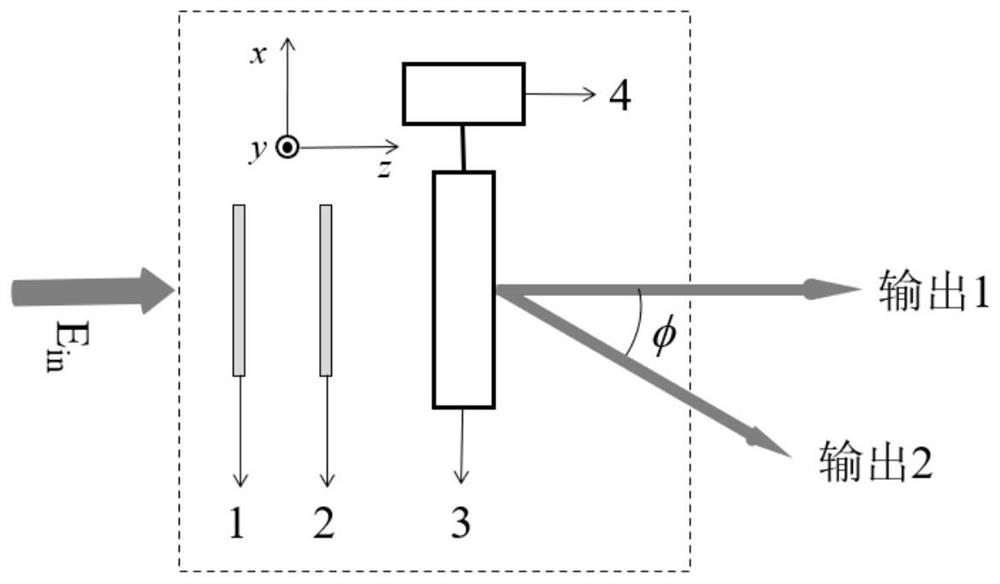

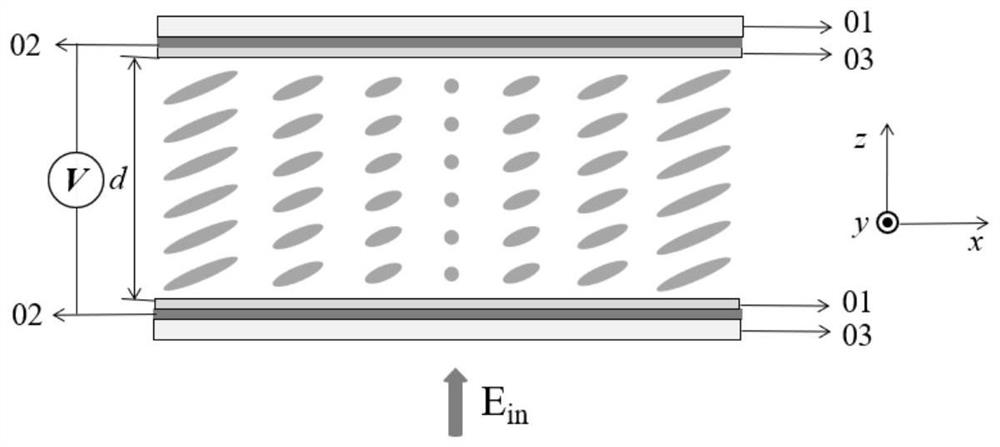

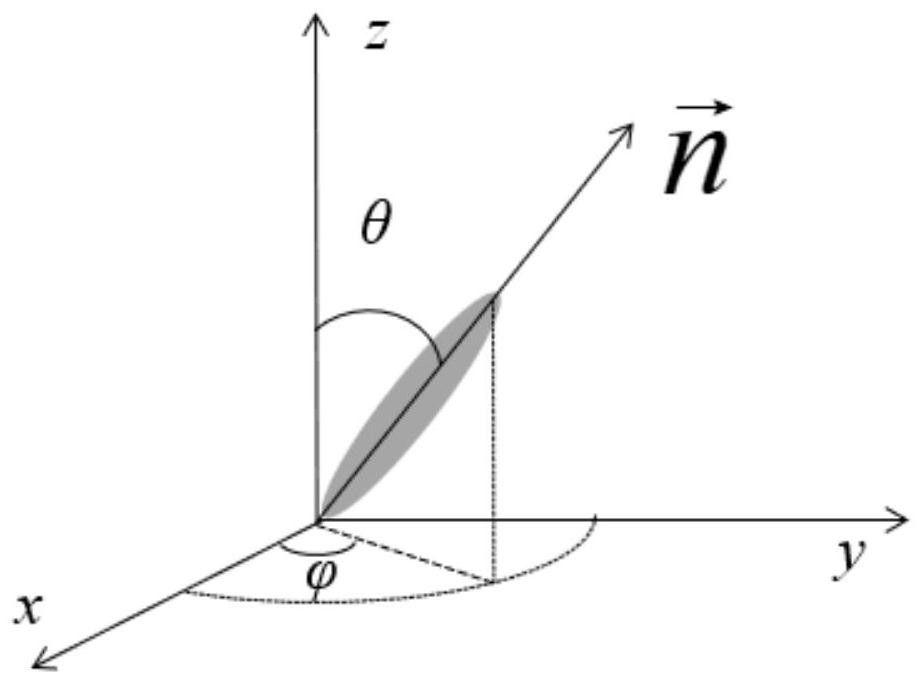

[0070] This embodiment provides an electronically controlled and adjustable polarization beam splitting device, which can directly decompose the incident light beam of any polarization state in a wide band into two beams of orthogonal circularly polarized light, that is, left-handed circularly polarized light and right-handed circularly polarized light. , and the energy splitting ratio of the two beams of circularly polarized light can be precisely and dynamically adjusted through external control voltage control. Such as figure 1 As shown, the polarizing beam splitting device with electrically controlled and adjustable splitting ratio includes a polarizer 1, an achromatic quarter-wave plate 2 and a liquid crystal polarization grating 3 that are arranged in sequence. Connected external control voltage driving device 4, wherein the angle between the polarizing direction of the polarizer and the fast axis of the achromatic quarter-wave plate is 45 degrees.

[0071] It should be...

Embodiment 2

[0089] This embodiment provides an electronically controlled and adjustable polarization beam splitting device, which can directly decompose an incident beam of any polarization state into two beams of linearly polarized light with the same polarization, and the beam splitting ratio of the two beams of linearly polarized light can be determined by External control voltage control realizes precise dynamic regulation. The method for realizing the same polarization beam splitting of any beam is the same as the method for realizing the orthogonal polarization beam splitting of any beam, but realizing the same polarization beam splitting needs to add an analyzer at the output end of the orthogonal polarization beam splitting device (embodiment 1) . Such as Figure 6 As shown, a polarizing beam splitting device with electrically controlled and adjustable splitting ratio, including a polarizer 1, an achromatic quarter-wave plate 2, a liquid crystal polarization grating 3 and an anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com