Efficient desulfurization tower

A desulfurization tower and high-efficiency technology, applied in the field of chemical equipment, can solve problems such as unfavorable system normal operation and increased resistance, and achieve the effects of optimizing the uniform distribution of flue gas, increasing absorption time, and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

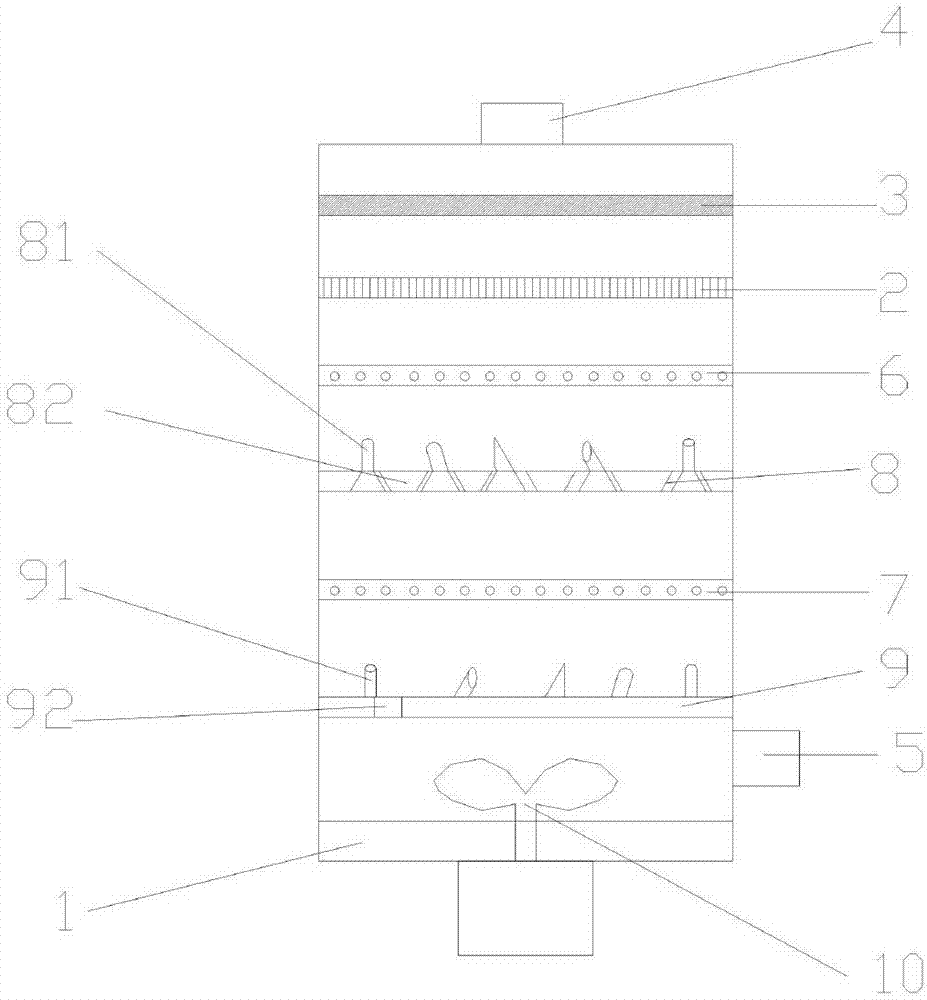

[0015] The purpose of this embodiment is to provide a high-efficiency desulfurization tower, such as figure 1 and figure 2 As shown, the desulfurization tower includes a tower body, and a slurry pool 1, a rectification device, a spray layer 2, a mist eliminator 3, and a flue outlet 4 are sequentially arranged in the tower body from bottom to top. A flue gas inlet 5 is provided, and the flue gas inlet 5 is arranged between the rectification device and the slurry pool 1; it can optimize the uniform distribution of flue gas on the entire cross section of the desulfurization tower, and greatly optimize the flow field in the desulfurization tower.

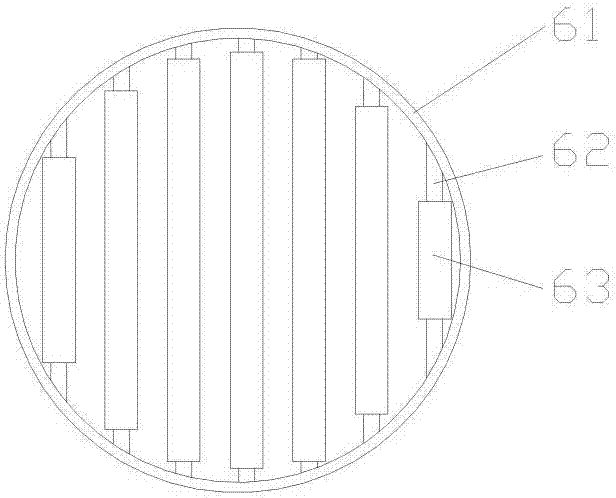

[0016] The rectification device includes a first rectification layer 6 and a second rectification layer 7, and each rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com