Electric-heating film and manufacturing method thereof

A technology of electric heating film and tin tetrachloride, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of poor temperature resistance, limited application range, fast power attenuation, etc., and achieve good physical and chemical properties and practical voltage The effect of wide range and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one: formula ratio is calculated by weight percentage in the embodiment of the present invention:

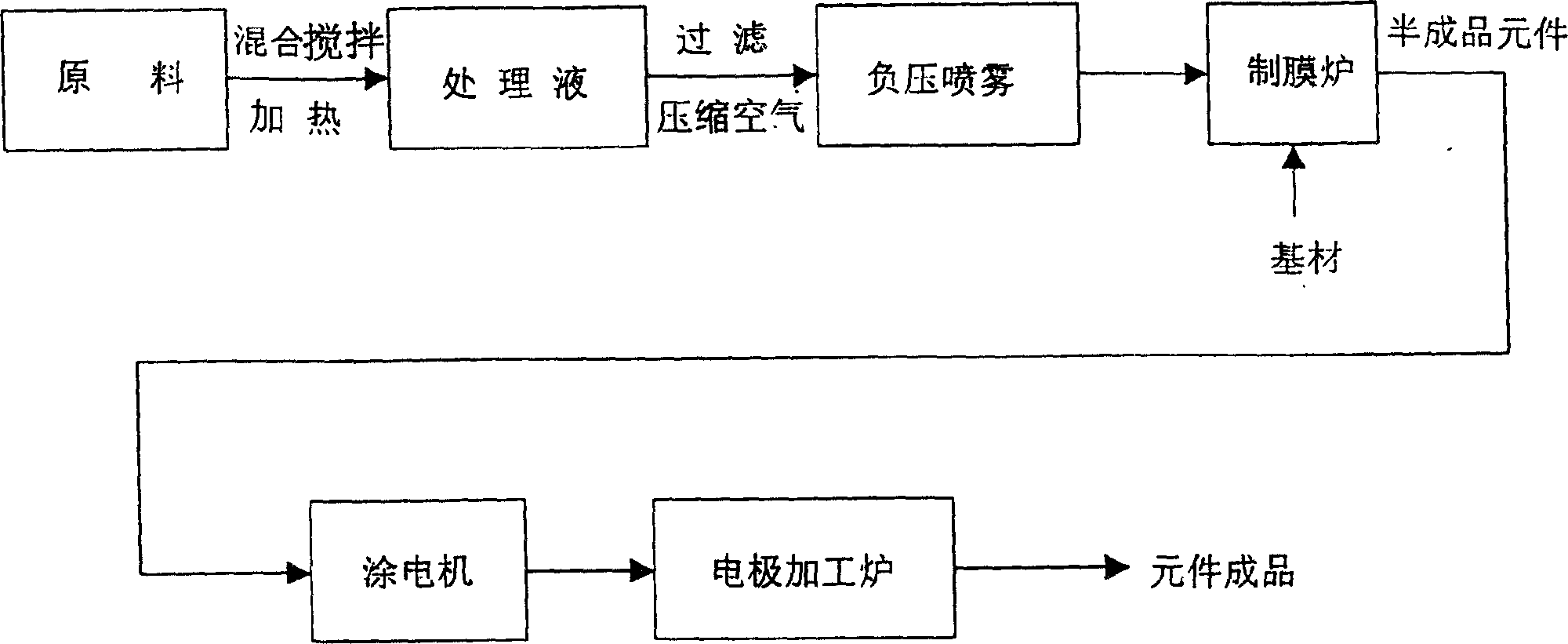

[0026] 1. Production of electrothermal film treatment fluid:

[0027] In the present invention, tin tetrachloride 40, titanium trichloride 40, antimony trichloride 0.1, calcium dichloride 0.1, isopropanol 2, ethanol 10, and water 2 are placed in a mixing heater and heated to 70° C., stirred. Evenly, all the solids in the raw materials are dissolved, and then filtered when the cooling temperature is normal temperature, and then the electrothermal film treatment liquid is ready for use.

[0028] 2. Production of semi-finished electric heating film:

[0029] The invention adopts silicon carbide as the film-making furnace core, the electric heating power is 9KW-12KW, and the thyristor element is selected as the temperature control board. When the furnace temperature is controlled at 650°C, put the substrate silicon carbide into the furnace for heating. When the s...

Embodiment 2

[0041] Embodiment two: formula ratio is calculated by weight percentage:

[0042] In the present embodiment, tin tetrachloride 45, titanium trichloride 35, antimony trichloride 0.2, calcium dichloride 0.2, isopropanol 2.5, ethanol 11.5, water 3.5, adopt the same production process in embodiment one An electrothermal film that meets the requirements of the weight index is obtained. In this embodiment, the raw material mixing heating temperature is 80°C; the electric heating power is 10kw; the furnace temperature control temperature is 750°C; the electrothermal film treatment solution is sprayed 4 times, and the injection volume is 1.5ml each time.

Embodiment 3

[0043] Embodiment three: formula ratio is calculated by weight percentage:

[0044] Get tin tetrachloride 50, titanium trichloride 30, antimony trichloride 0.3, calcium dichloride 0.3, isopropanol 3, ethanol 13, water 5 in the present embodiment, adopt the production in embodiment one, two The same method can be used to produce electrothermal film that meets the requirements.

[0045] Purpose and principle of the present invention are as follows:

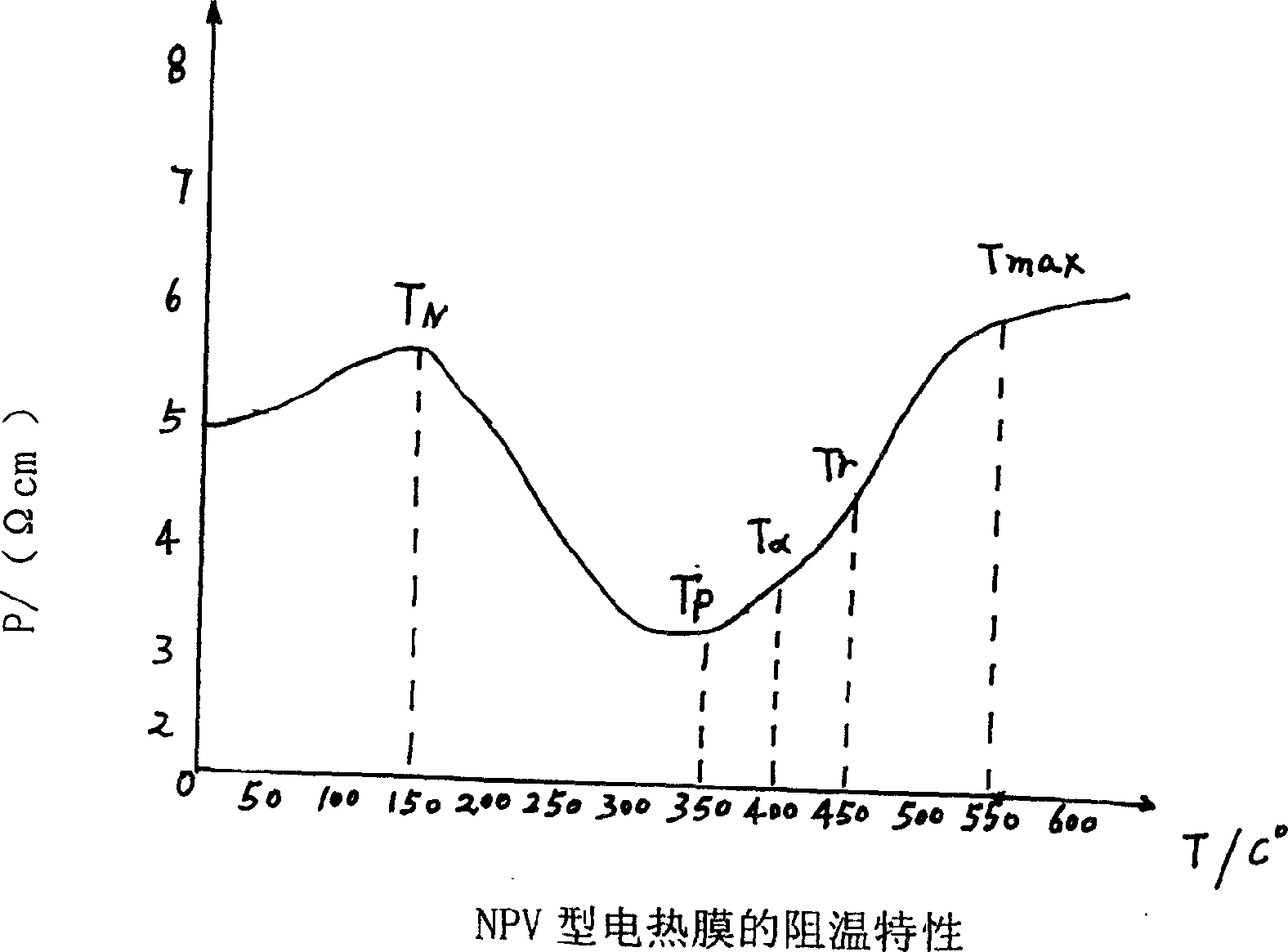

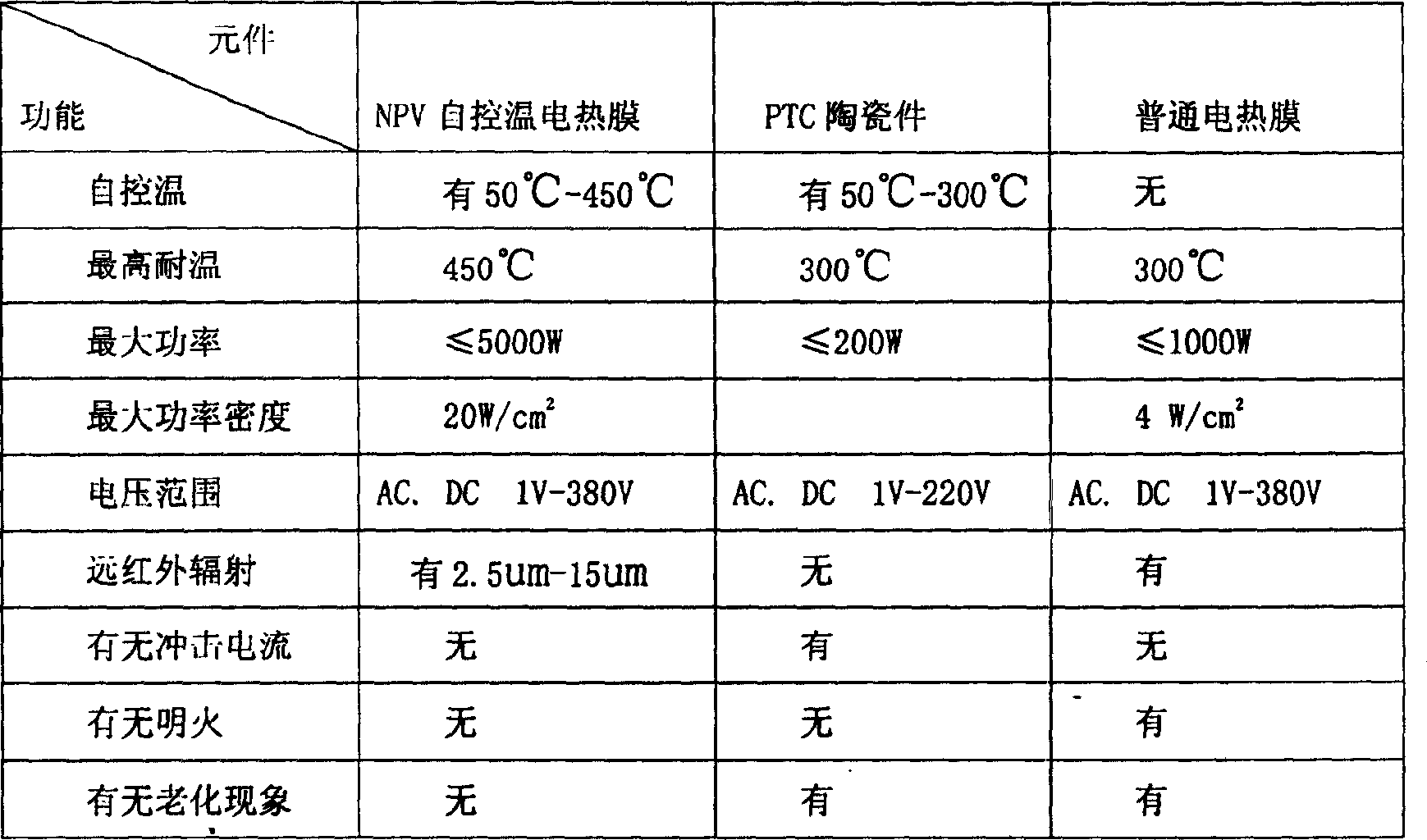

[0046] The functional electrothermal film of the present invention is an electrothermal film technology with PTC function. Before the Curie temperature, it is a negative temperature coefficient (NTC) in which the resistance decreases with the increase of temperature, and after the Curie temperature, the positive temperature coefficient (PTC) characteristic of the resistance increases with the increase of temperature is integrated N-PTCR - Materials with V-type resistance-temperature characteristic curves. This process is: on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com