Preparation method of graphene-titanium dioxide compound photocatalyst

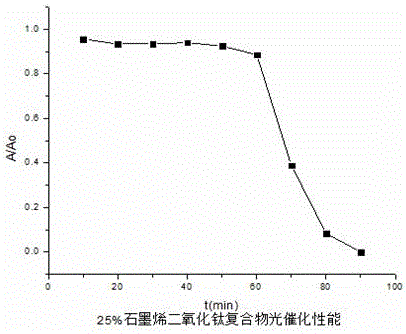

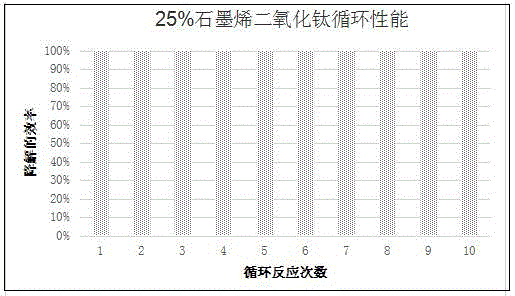

A titanium dioxide and photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reducing the photocatalytic performance of titanium dioxide, reducing the photocatalytic performance, and low photocatalytic efficiency, etc. The effect of good photocatalytic performance, good cycle performance, good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

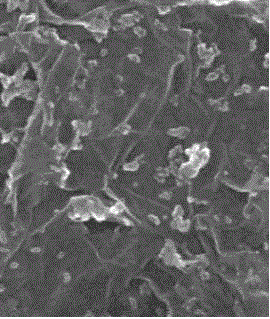

Image

Examples

Embodiment 1

[0029] In the mixture of 500mg graphite powder and 2.0g sodium nitrate, add 18ml of concentrated sulfuric acid with a mass concentration of 98%, and stir the reaction at a temperature lower than 5°C for 1h; then within 0.5h, slowly add 3.0g potassium permanganate powder, react for 1.5h at a temperature lower than 5°C; raise the temperature of the above reaction system to 35°C, keep it warm for 1h, add 40ml of deionized water to the reactor after the heat preservation, and then raise the temperature to 100°C , kept warm for 15min; then the reaction product was cooled to room temperature, diluted with 70 milliliters of deionized water, and then 10 milliliters of hydrogen peroxide solution with a mass concentration of 35% was added thereto; then the reaction product was filtered, and the obtained filter cake was first Wash three times with 400 ml of hydrochloric acid with a mass concentration of 5%, and then wash three times with deionized water, and finally use a dialysis bag to ...

Embodiment 2

[0031]10 ml of a 1 mg / l graphene dispersion was prepared using the graphene oxide of Example 1.

[0032] Hexadecyltrimethylammonium bromide 5.8g was dissolved in 10 milliliters of n-pentanol and 60 milliliters of n-hexane, then 10 milliliters of graphene dispersion (1mg / ml) was supersonicated for 20 minutes with an ultrasonic cleaner to form a uniform dispersion , add to the above suspension while stirring within 30 minutes; when the solution becomes a golden emulsion, add 1.524 ml of titanium dioxide, and then keep stirring the solution, when the liquid becomes a transparent microemulsion, pour it into a high-pressure reactor , placed in an oven at 200 degrees Celsius for 6 hours; take out the reactant, place the reaction product in a rotary evaporator to remove organic reagents, then repeatedly use water and ethanol to remove surfactants and other impurities, and finally place the sample at 80 degrees Celsius to dry for 2 hours.

Embodiment 3

[0034] 20 ml (1 mg / l) of the graphene dispersion was prepared using the graphene oxide of Example 1.

[0035] Hexadecyltrimethylammonium bromide 11.6g was dissolved in 20 milliliters of n-pentanol and 120 milliliters of n-hexane, then 20 milliliters of graphene water dispersion liquid (1mg / ml) was supersonicated for 20 minutes with an ultrasonic cleaner to form a uniform dispersion solution, add it to the above suspension while stirring within 30 minutes; when the solution becomes a golden emulsion, add 3.048 ml of titanium dioxide, and then keep stirring the solution, when the liquid becomes a transparent microemulsion, pour it into the high-pressure reactor , placed in an oven at 200 degrees Celsius for 6 hours; take out the reactants, place the reaction product on a rotary evaporator to remove organic reagents, wash repeatedly with water and ethanol to remove surfactants and other impurities, and place the final sample at 80 degrees Celsius to dry for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com