Preparation method of boron-doped graphene/TiO2 nanorod photocatalytic material

A photocatalytic material, graphene technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, nanotechnology, etc., can solve the problems of high requirements for reaction equipment, complicated preparation process, pollution of the environment, etc., to achieve high conductivity and Effect of Surface Loading Free Charge Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

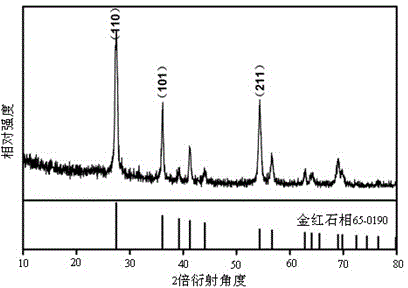

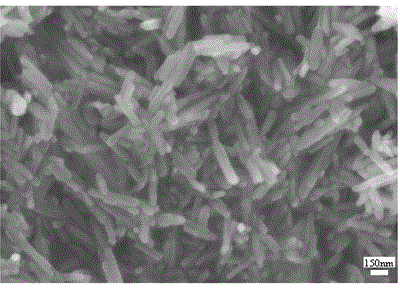

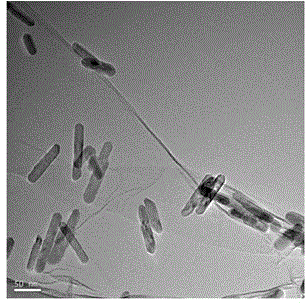

Embodiment 1

[0029] Graphene oxide (GO) was prepared by the method disclosed in the American Chemical Society "Nano" journal, Volume 4, 2010, page 4806-4814; weigh 80 mg of graphene oxide, add 25 ml of deionized water, and ultrasonically disperse for 1 hour to obtain graphene oxide Dispersion liquid: adding 0.3g sodium borohydride and 8.45mL concentration of mass percent to the graphene oxide dispersion liquid is 20% titanium trichloride solution, sodium borohydride is used as boron source and reducing agent, and titanium trichloride is used as titanium source; Stir on a magnetic stirrer for 30 minutes, then ultrasonically stir for 40 minutes, and finally transfer the solution to a hydrothermal kettle, and conduct a hydrothermal reaction at a temperature of 180°C for 14 hours to obtain a precipitate; use deionized water and ethanol to wash the precipitate separately by centrifugation After that, it was vacuum-dried at 60 °C for 10 hours, and then ground into a uniform powder with an agate m...

Embodiment 2

[0037] Graphene oxide was prepared by the method disclosed in the document ACS Nano. 2010, 4(8): 4806-4814; 40 mg of graphene oxide was weighed, added to 20 mL of deionized water, and ultrasonically dispersed for 0.75 hours to obtain a graphene oxide dispersion, and then added 0.61g of sodium borohydride and 3.38mL of titanium trichloride solution with a concentration of 20% by mass, stirred on a magnetic stirrer for 40 minutes, then ultrasonically stirred for 30 minutes, and finally transferred the solution into a 50mL hydrothermal kettle, and heated at 160°C After reacting for 16 hours, the obtained precipitate was successively washed with deionized water and ethanol by centrifugation, dried in vacuum at 50°C for 12 hours, and then ground into a uniform powder with an agate mortar to obtain a boron-doped graphene / rutile phase TiO 2 Nanorod composite photocatalytic materials.

Embodiment 3

[0039] Graphene oxide was prepared by the method disclosed in the document ACS Nano. 2010, 4(8): 4806-4814; 8 mg of graphene oxide was weighed, added to 15 mL of deionized water, and ultrasonically dispersed for 0.5 hours to obtain a graphene oxide dispersion, and then added 0.9g of sodium borohydride and 13.52mL of titanium trichloride solution with a mass percentage concentration of 20%, stirred on a magnetic stirrer for 50min, then ultrasonically stirred for 50min, and finally transferred the solution into a 50mL hydrothermal kettle, and hydrothermally heated at 200°C After reacting for 12 hours, the obtained precipitate was successively washed with deionized water and ethanol by centrifugation, dried in vacuum at 70°C for 8 hours, and then ground into a uniform powder with an agate mortar to obtain a boron-doped graphene / rutile phase TiO 2 Nanorod composite photocatalytic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com