Ammonia converter production optimization method based on data excavation technology

A technology of data mining and optimization methods, applied in instrumentation, adaptive control, control/regulation systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

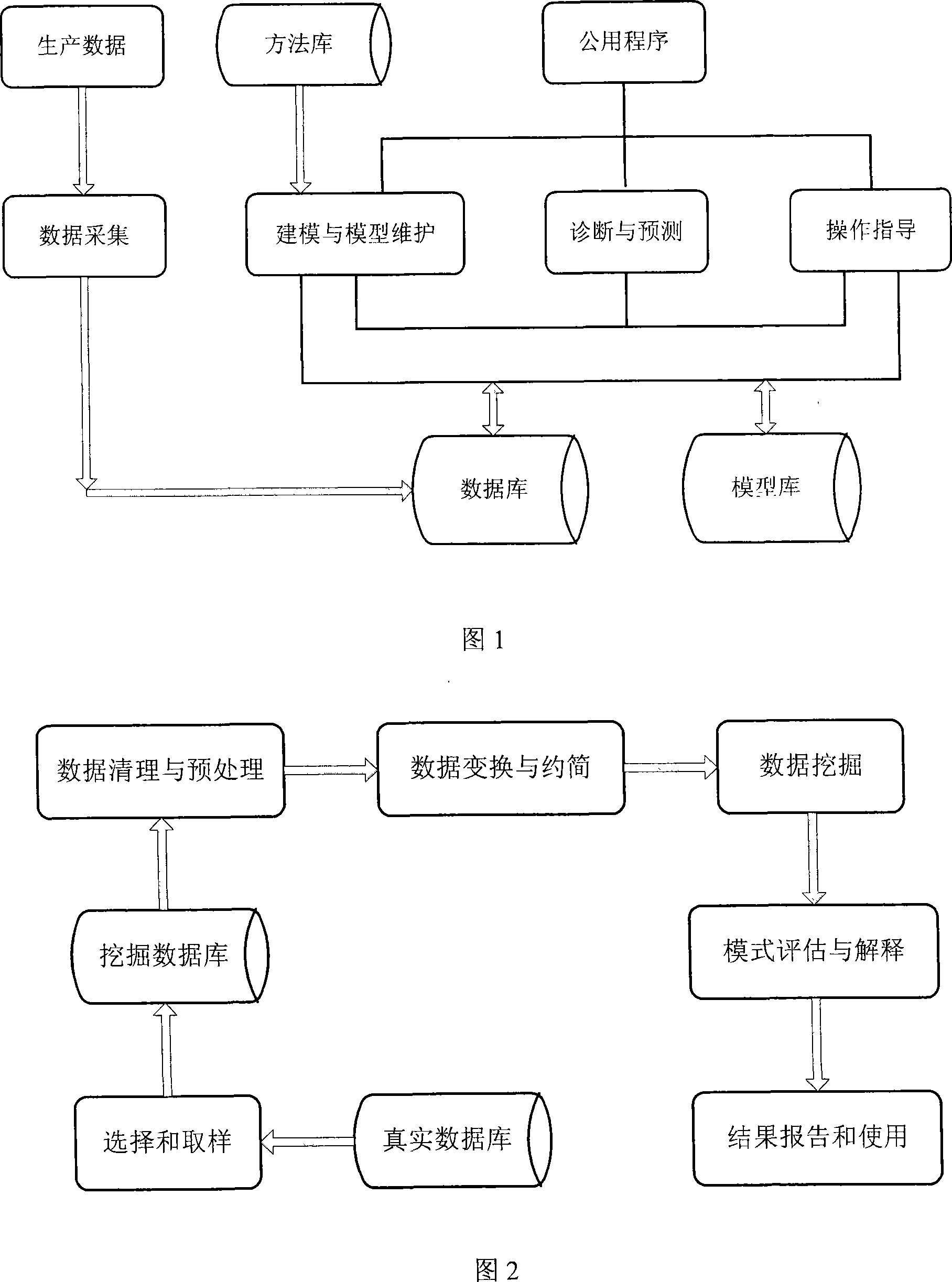

Method used

Image

Examples

Embodiment 1

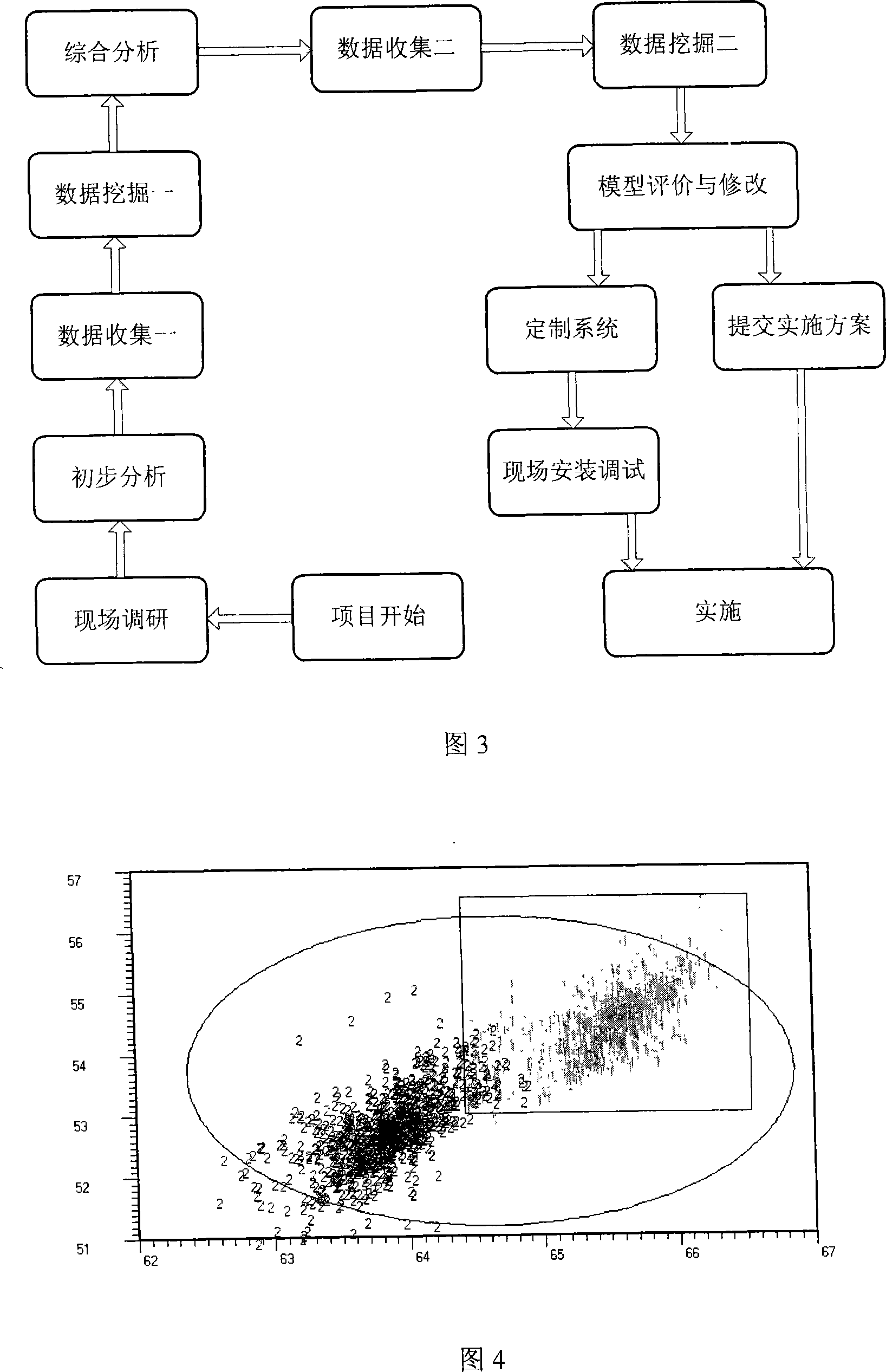

[0033] Example 1: Production Optimization Model of No. 1 Synthesis Plant

[0034] 1. Optimizing the target variable and optimizing the independent variable: the fresh gas entering the tower (FI0811a, Nm 3 / h) is the target variable, relevant process parameters such as fresh gas hydrogen content (AI0811c, %), cold shock three flow (FI0805a, Nm 3 / h), the inlet temperature of the first section of the synthesis tower (TI0801_2a, ℃), the outlet temperature of the second section of the synthesis tower (TI0801_5a, ℃), the temperature of the third section of the synthesis tower (TIC08004a_PV, ℃), the temperature of the third section of the synthesis tower (TI0801_12a, ℃), synthesis 42 process parameters such as the temperature of the fourth section of the tower (TI0801_16a, ℃), the inlet gas temperature of the waste boiler (TI0803a) and the outlet temperature of the water cooler (TI0807a, ℃) were analyzed as independent variables. Fresh gas volume greater than 26500Nm 3 The sample ...

Embodiment 2

[0043] Example 2: Production Optimization Model of No. 2 Ammonia Synthesis Unit

[0044] 1. Optimizing the target variable and optimizing the independent variable: the fresh gas entering the tower (FI0811b, Nm 3 / h) is to optimize the target variable, relevant process parameters such as fresh gas hydrogen content (AI0811c, %), the first stage inlet temperature of the synthetic tower (TI0801_7b, ℃), the first stage outlet temperature of the synthetic tower (TIC0801_2b_PV, ℃), the second stage temperature of the synthetic tower (TI0801_3b, ℃), the temperature of the second stage of the synthetic tower (TI0801_10b, ℃), the temperature of the third stage of the synthetic tower (TIC0801_12b_PV, ℃), the temperature of the third stage of the synthetic tower (TI0801_6b, ℃), the temperature of the waste boiler inlet gas (TI0804b) and the water cooler A total of 42 process parameters such as outlet temperature (TI0807b, °C) were analyzed as independent variables. Fresh gas volume great...

Embodiment 3

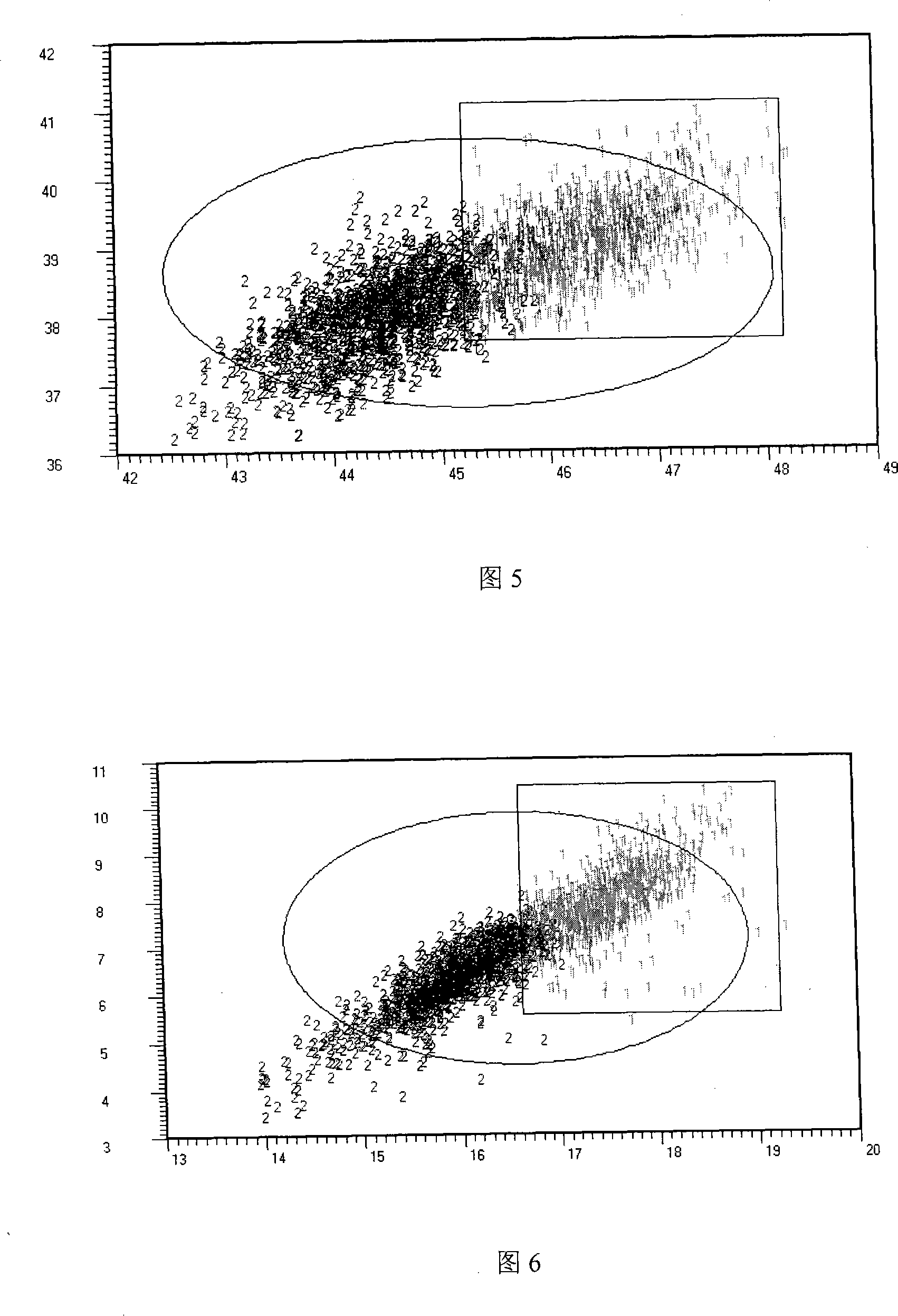

[0053] Example 3: Production Optimization Model of No. 3 Ammonia Synthesis Unit

[0054] 1. Optimizing the target variable and optimizing the independent variable: take the fresh gas entering the tower (FI0811c, Nm 3 / h) is to optimize the target variable, relevant process parameters such as fresh gas hydrogen content (AI0811c, %), cycle gas hydrogen content (AI0802c, %), synthesis tower one section inlet temperature (TI0801_2c, ℃), synthesis tower one section outlet temperature ( TIC0801_4c_PV, ℃), the temperature of the second stage of the synthesis tower (TIC0801_6c_PV, ℃), the temperature of the third stage of the synthesis tower (TIC0801_9c_PV, ℃), the temperature of the third stage of the synthesis tower (TI0801_12c, ℃), the secondary outlet temperature (TI0816c) and the outlet temperature of the water cooler (TI0820c, ℃), etc. 52 process parameters are analyzed as independent variables. Fresh gas volume greater than 27500Nm 3 The sample of / h is an excellent class sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com