Field welding repair method particularly suitable for bead weld layer defects on low alloy and carbon steel

A low-alloy steel, on-site welding technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of reducing the ability of the surfacing layer to resist peeling, affecting the structural safety, reducing the toughness of the joint surface, etc. Mitigation of adverse effects, simple implementation method, effect of reducing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0044] see Figure 5 with 6 , are respectively macroscopic metallographic photographs and microscopic metallographic photographs of the surfacing layer metal processed according to the method of the present invention, the surfacing layer is 309L+308L stainless steel, and the base material is 16MND5 low-alloy steel.

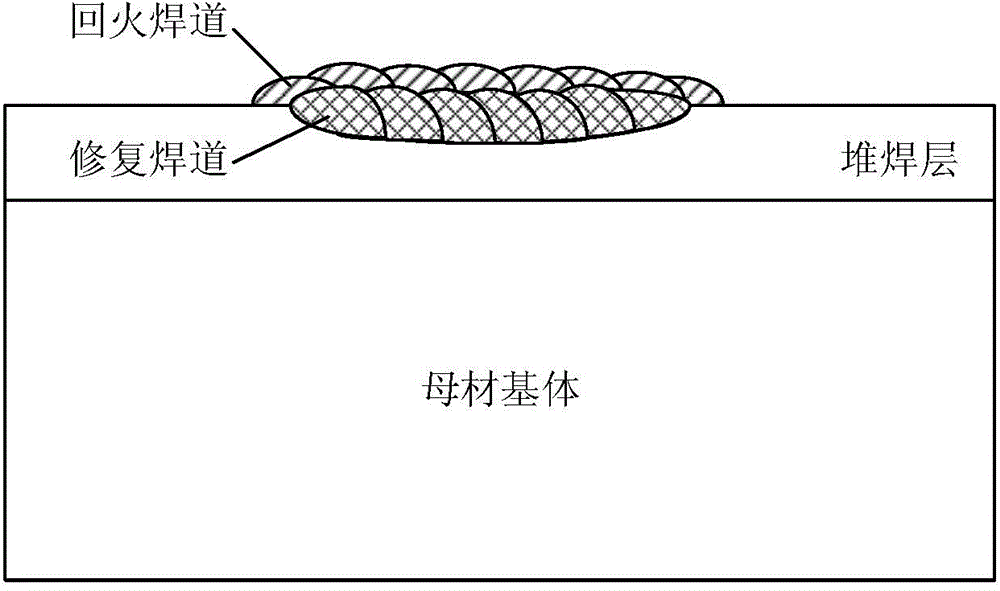

[0045] see Figure 7 , which shows the comparison of the microhardness of the repair welding area after the tempering bead treatment and that without the tempering bead treatment, from which it can be seen that after the tempering bead treatment, the hardness of the base metal area near the bonding surface obviously decased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com