Blast-furnace pressure-discharging gas recovering device and method

A recovery device and gas technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as polluting the environment, wasting high-pressure gas, etc., and achieve the effects of convenient on-site implementation, reliable operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

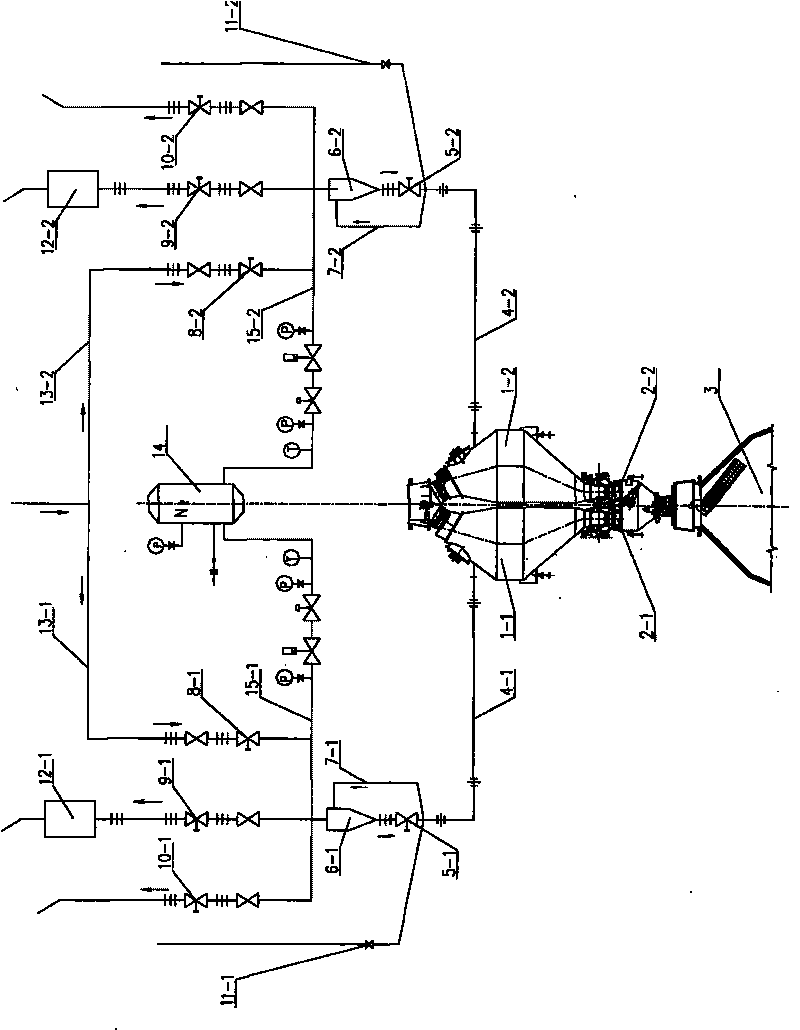

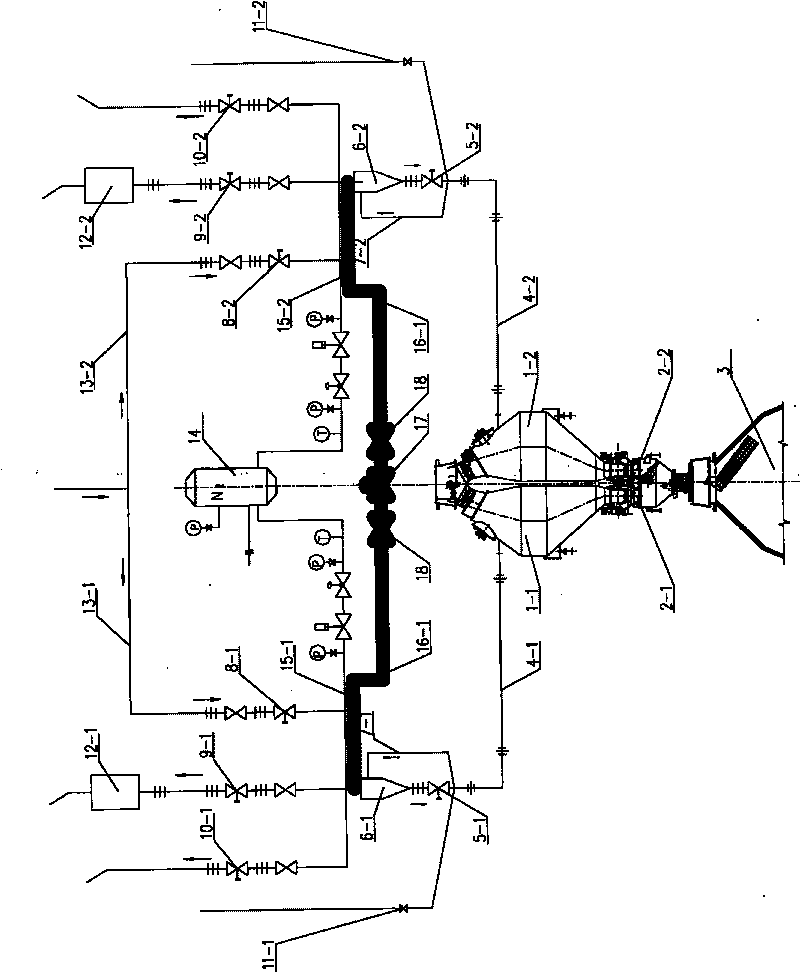

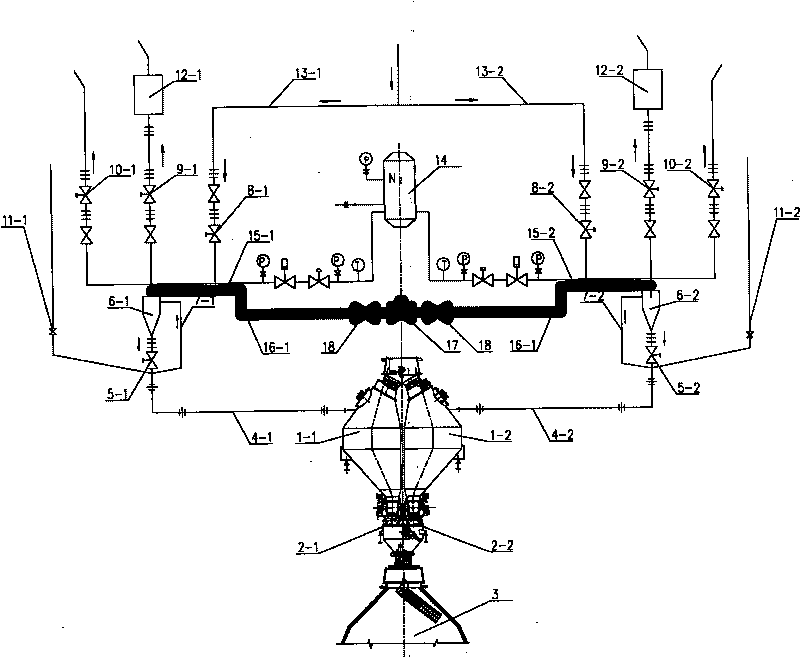

[0014] Attached below figure 2 The present invention is described further:

[0015] attached figure 2 It is a tank combining device, and the feed tank 1 is a tank combining feed tank 1-1 and feed tank 1-2.

[0016] The feed tank 1 of the three-tank device is feed tank 1-1, feed tank 1-2 and feed tank 1-3, and the attached figure 2 the same way.

[0017] Take the material tank 1-1 as an example:

[0018] Material tank 1-1 is connected to blast furnace 3 through sealing valve 2-1, material tank 1-1 is connected to pressure equalizing system 4-1, and secondary pressure equalizing system pipeline 15-1 is connected to the cyclone of pressure equalizing system 4-1. The pipeline above the dust collector 6-1 is connected; the pressure exhaust gas recovery pipeline 16-1 of the pressure exhaust gas recovery system is also connected to the pipeline above the cyclone dust collector 6-1.

[0019] Pressure equalizing exhaust system 4-1 includes equalizing valve 5-1, cyclone dust col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com