Multifunctional operation monitoring method for polythene production process

A production process and operation monitoring technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problem that special control modules cannot be directly embedded, and achieve perfect safety monitoring capabilities, convenient system upgrades, and easy spare parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

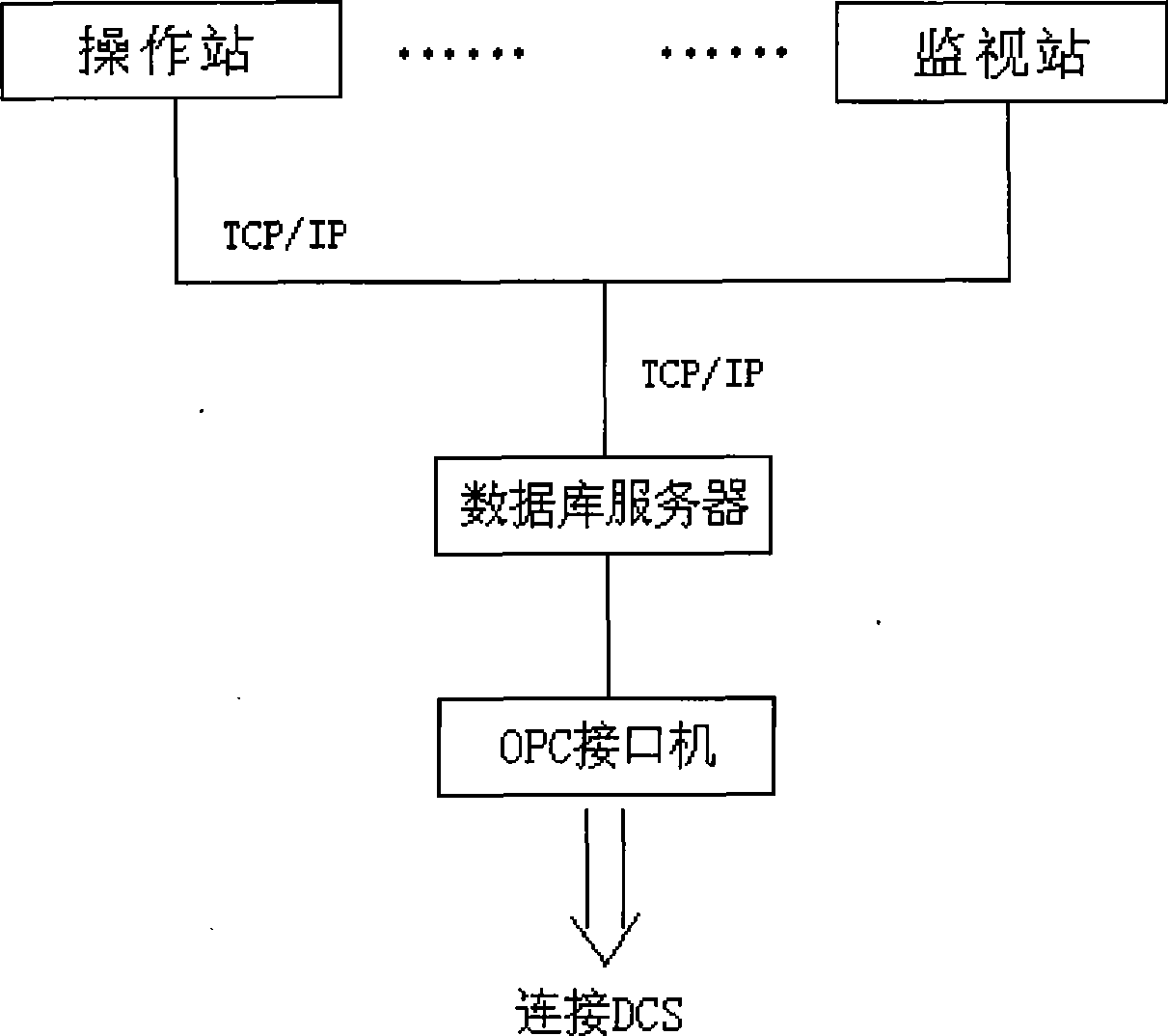

[0014] Polyethylene production process multi-functional operation monitoring method of the present invention relies on the three-layer architecture of Internet network connection to realize, as figure 1 shown. The monitoring system is composed of OPC interface machine, database server, operation station group and monitoring station group. The interconnection relationship is as follows: the OPC interface machine is connected to the DCS system on the production site to provide production process data for the database server, and the database server is connected to the OPC interface machine. The data is obtained in the computer, and the operation station group and the monitoring station group are connected to the database server through industrial Ethernet, and can read and process the data in the database server. The OPC interface machine is a data interface device for data interaction with the DCS in the present invention, and it is connected with the DCS system through a DCS d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com