Method for enhancing oil well cement slurry

A technology of oil well cement slurry and oil encounter, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of many uncertain factors, many influencing factors, wellbore temperature and pressure changes, etc., and is beneficial to on-site implementation. The method Simple, Wide-Source Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

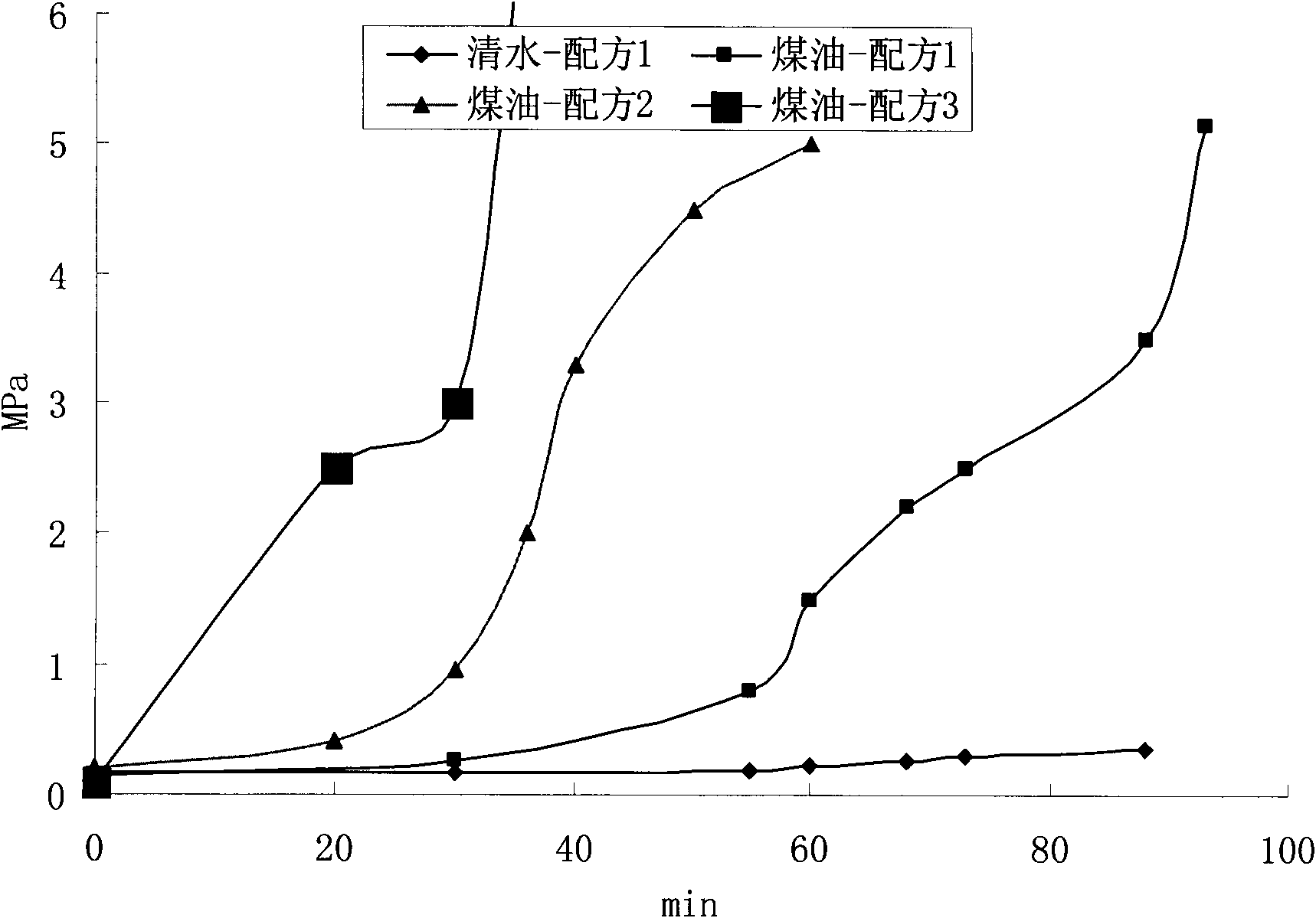

Image

Examples

Embodiment 1

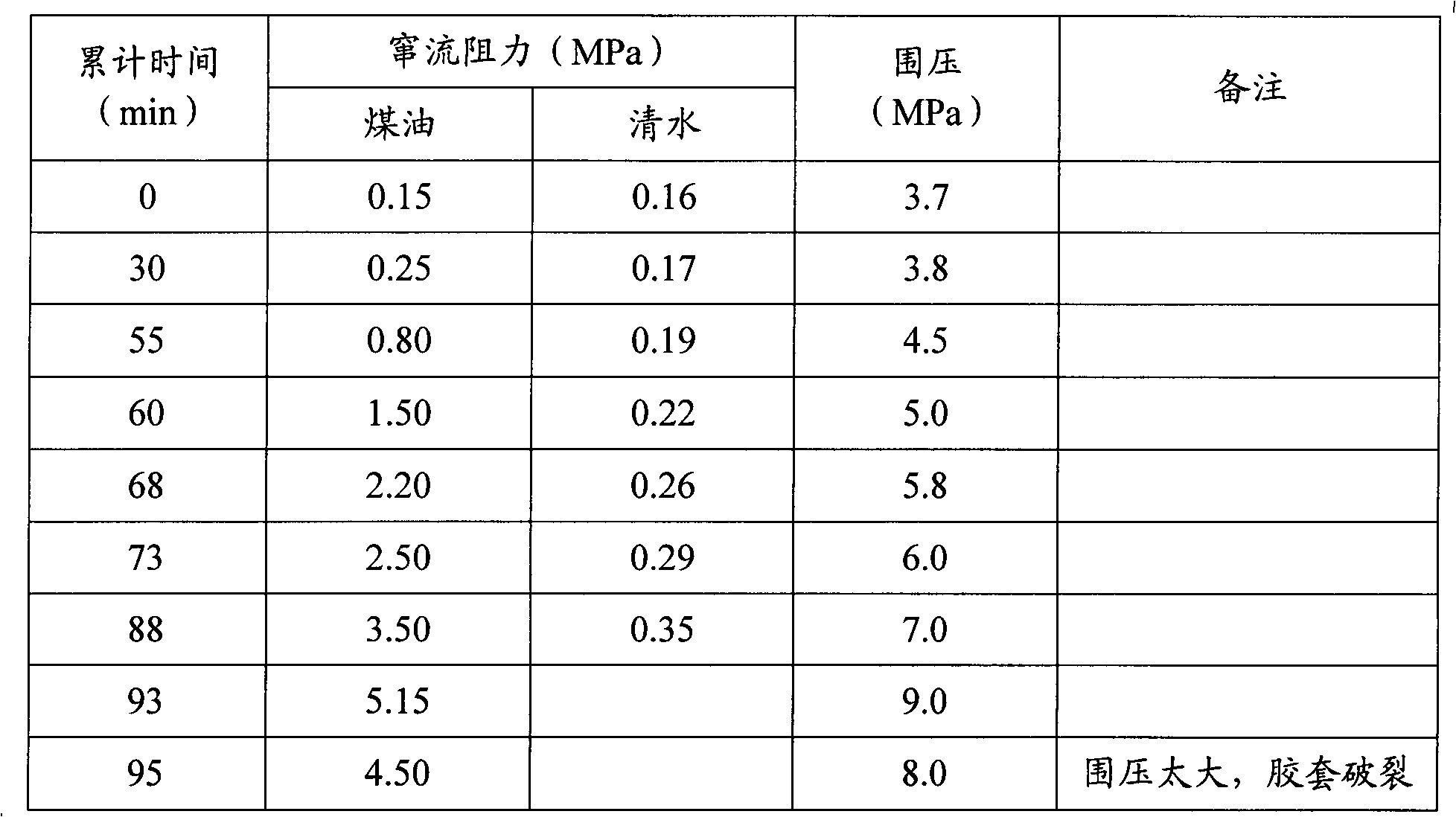

[0021] The cement slurry system used in the experiment is as follows:

[0022] 800g Xinjiang G grade oil well cement + 1.5% ST300C + 7% ST300L + 0.4% SXY-2 + 45% water

[0023] The specific additives in the formula are: ST300C is a crosslinking agent, ST300L is a fluid loss reducer, and SXY-2 is a dispersant.

[0024] The above cement slurry system adopts the mass percentage of each admixture and cement, and the density of the cement slurry is 1.89g / cm 3 .

[0025] In the case of high-speed stirring, an oil-absorbing resin accounting for 1% of the total mass of the cement solid phase and having a particle size of 80 meshes was mixed into the above-mentioned cement slurry and stirred evenly. In this example, the oil-absorbing resin was made of methacrylate and styrene. Monomer, ethylene glycol acrylate as cross-linking agent, and high oil-absorbing resin synthesized by suspension polymerization method.

[0026] Table 1 The cross-flow plugging test data of Example 1 (test tem...

Embodiment 2

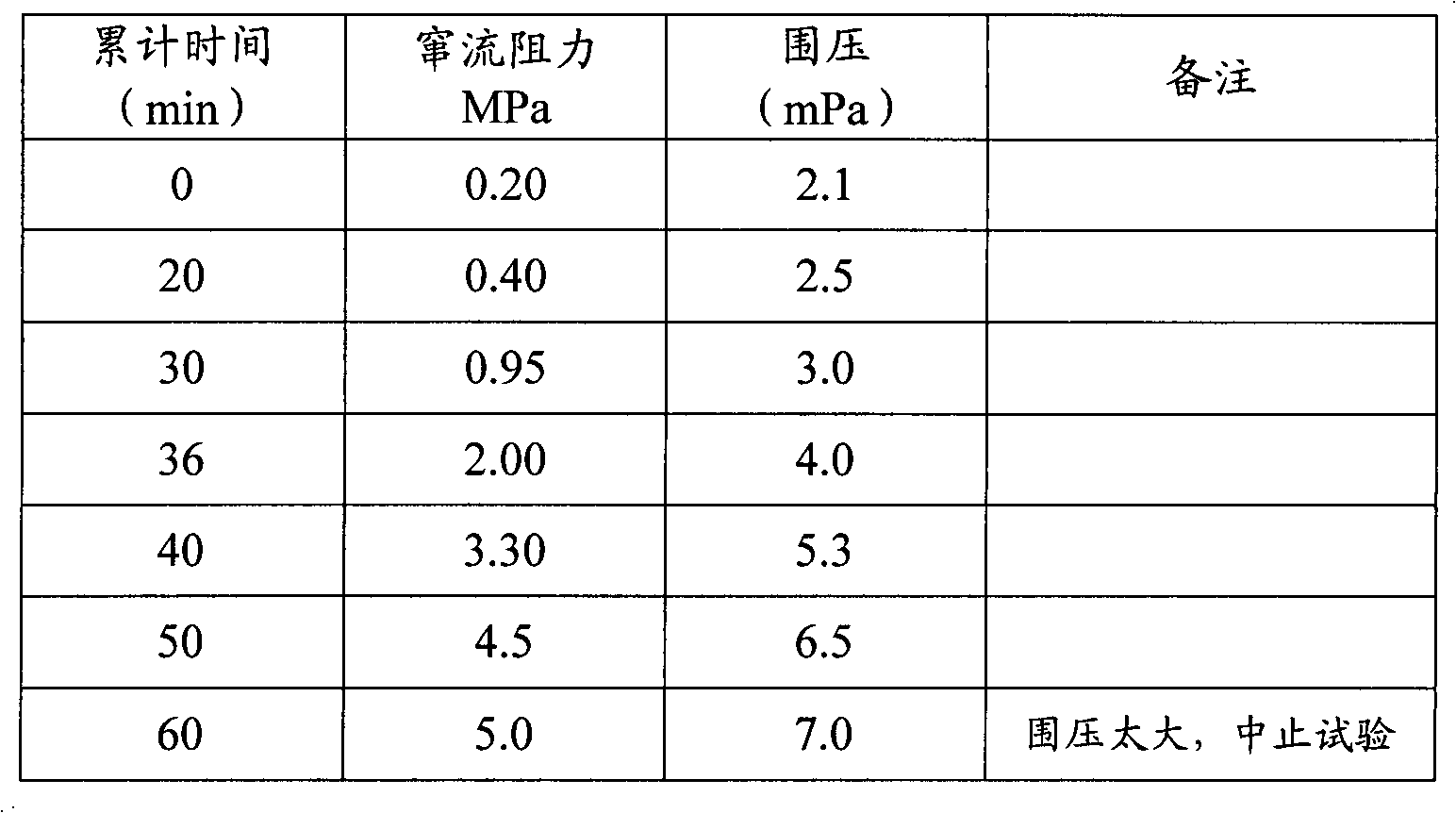

[0029] The cement slurry system used in the experiment is as follows:

[0030] 800g Xinjiang G grade oil well cement + 3% WG + 1.2% LT-2 + 0.6% SXY-2 + 0.2% ST200R + 45% water

[0031] The specific additives in the formula are: WG is micro silicon, LT-2 is fluid loss reducer, SXY-2 is dispersant, and ST200R is retarder.

[0032] The above cement slurry system adopts the mass percentage of each admixture and cement, and the density of the cement slurry is 1.89g / cm 3 .

[0033] In the case of high-speed stirring, an oil-absorbing resin with a particle size of 80 meshes, accounting for 2% of the total mass of the cement solid phase, was mixed into the above-mentioned cement slurry. The oil-absorbing resin in this example is also based on methacrylate and styrene. Body, ethylene glycol acrylate as crosslinking agent, and the super oil-absorbing resin synthesized by suspension polymerization.

[0034] Table 2 Example 2 kerosene channeling plugging test data (test temperature 27°...

Embodiment 3

[0037] The cement slurry system used in the experiment is as follows:

[0038] 800g Xinjiang G grade oil well cement + 105% Fe 2 o 3 +3%WG+(25%D600G+1.5%D080A+2%D701+0.5%D175)+57%Water

[0039] The additives in the formula are: WG is micro silicon, D600G is fluid loss reducer, D080A is dispersant, D701 is stabilizer, and D175 is defoamer.

[0040] The above cement slurry system adopts the mass percentage of each admixture and cement, and the cement slurry density is 2.40g / cm 3 .

[0041] In the case of high-speed stirring, an oil-absorbing resin with a particle size of 80 meshes, accounting for 3% of the total mass of the cement solid phase, was mixed into the above cement slurry. The oil-absorbing resin in this example is also based on methacrylate and styrene. Body, ethylene glycol acrylate as crosslinking agent, and the super oil-absorbing resin synthesized by suspension polymerization.

[0042] Table 3 Example 3 kerosene channeling plugging test data (test temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com