High-precision magnetic bearing axial control method based on interference observer

A technology of disturbance observer and control method, applied in the direction of control using feedback, bearings, shafts and bearings, etc., can solve the problems of inability to analyze disturbances in real time, failure to suppress, lack of disturbance records and quantitative analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

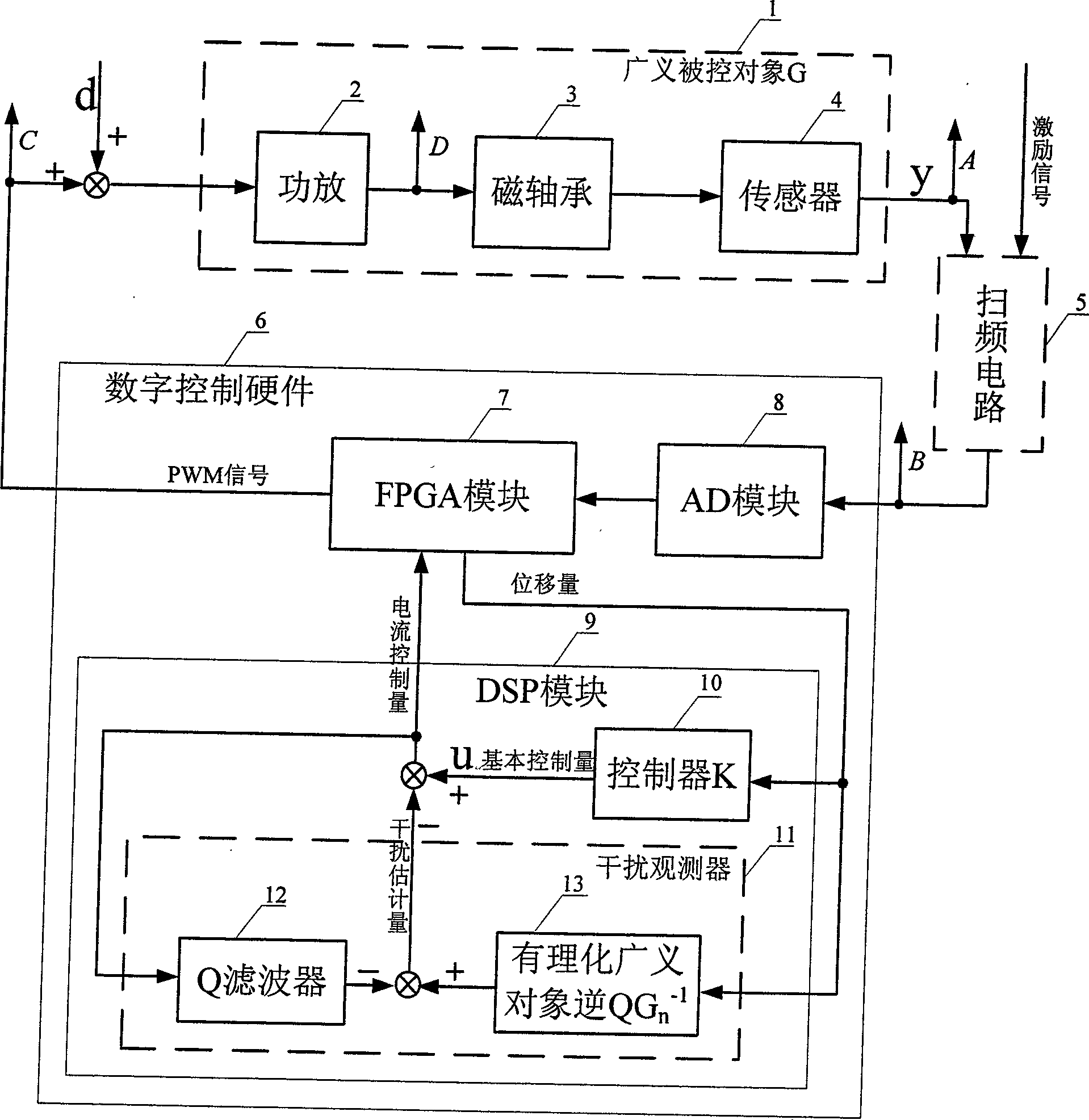

[0049] Such as figure 1 Shown, the system that realizes the method of the present invention comprises frequency sweep circuit 5 and digital control hardware 6, and wherein digital control hardware 6 comprises A / D module 8, DSP module 9 and FPGA module 7; Superimposed with the excitation signal, it is transmitted to the A / D module 8, and the FPGA module 7 receives the digital quantity converted by the A / D module 8, and then sends it to the DSP module 9, and the DSP module 9 uses the interference observer algorithm to calculate the current control value, and then transmits to the FPGA module 7, and then the FPGA module 7 converts the current control amount into a PWM form output, drives the power amplifier 2 to generate electromagnetic force to act on the magnetic bearing, and realizes the levitation function.

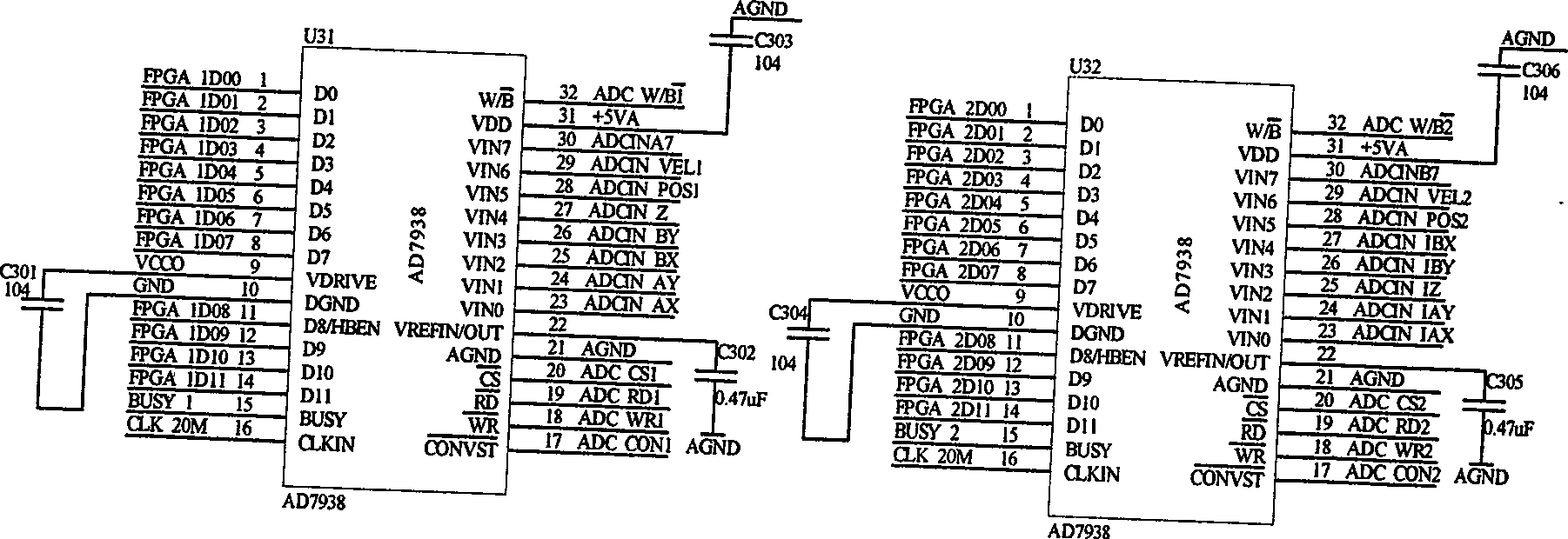

[0050] Such as figure 2 Shown is a schematic diagram of the A / D module 8 of the present invention, and the A / D module 8 is used to collect displacement values and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com