Two-stage stack-type cantilevered L-shaped blank wall and construction method thereof

An implementation method, cantilever technology, applied in excavation, water conservancy projects, artificial islands, etc., can solve problems such as large bending moment and shear force, single-stage cantilever retaining wall engineering application restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

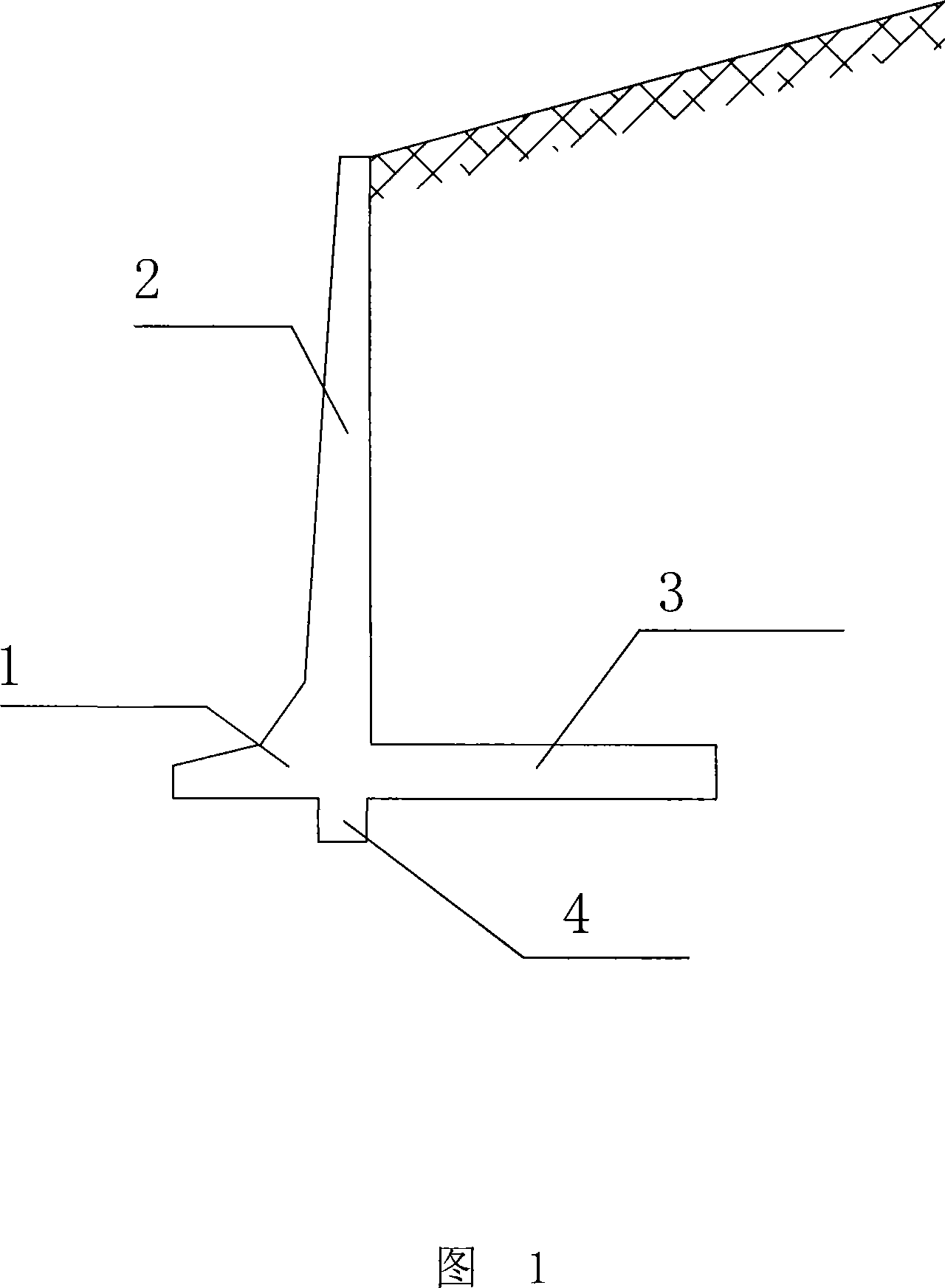

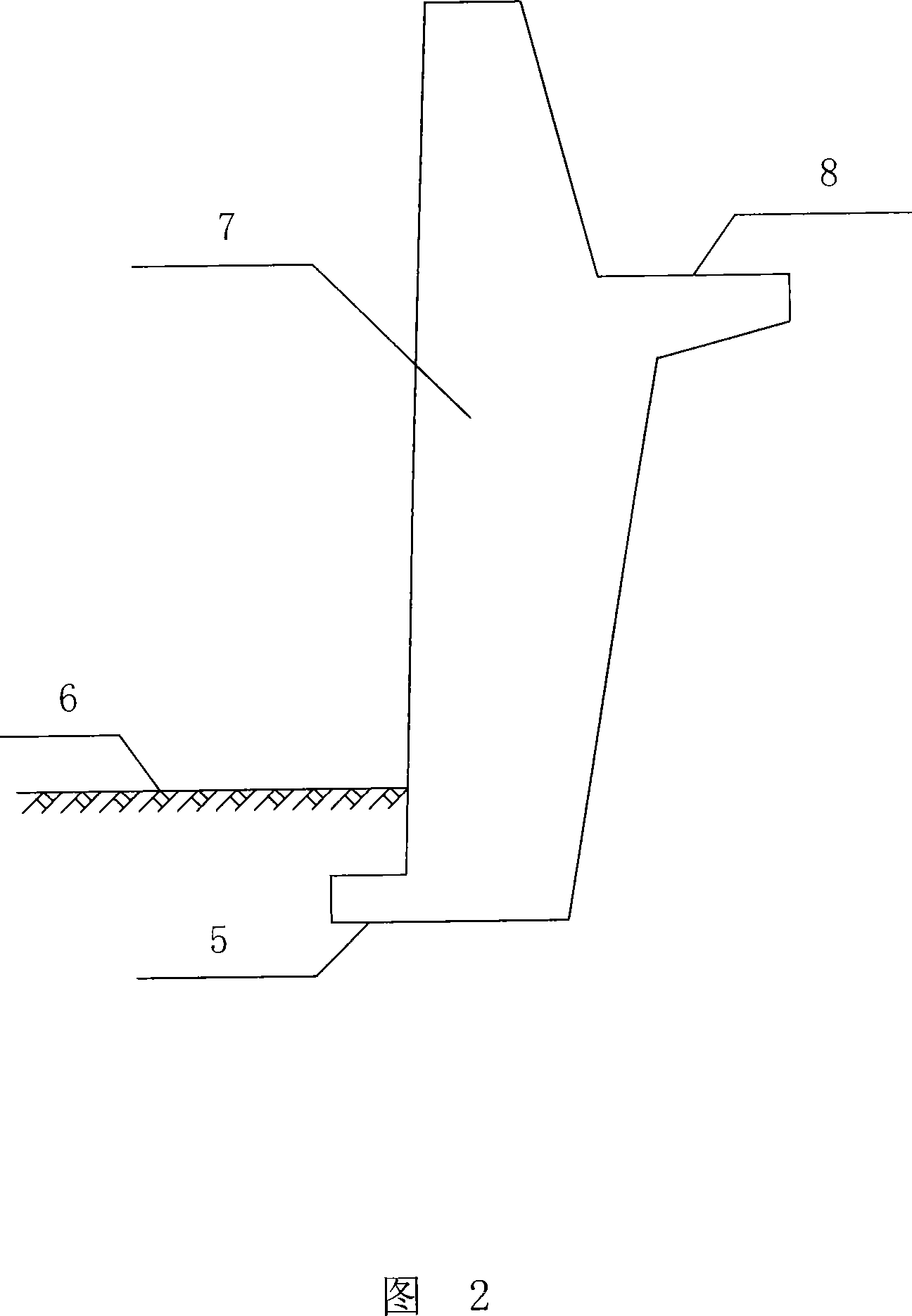

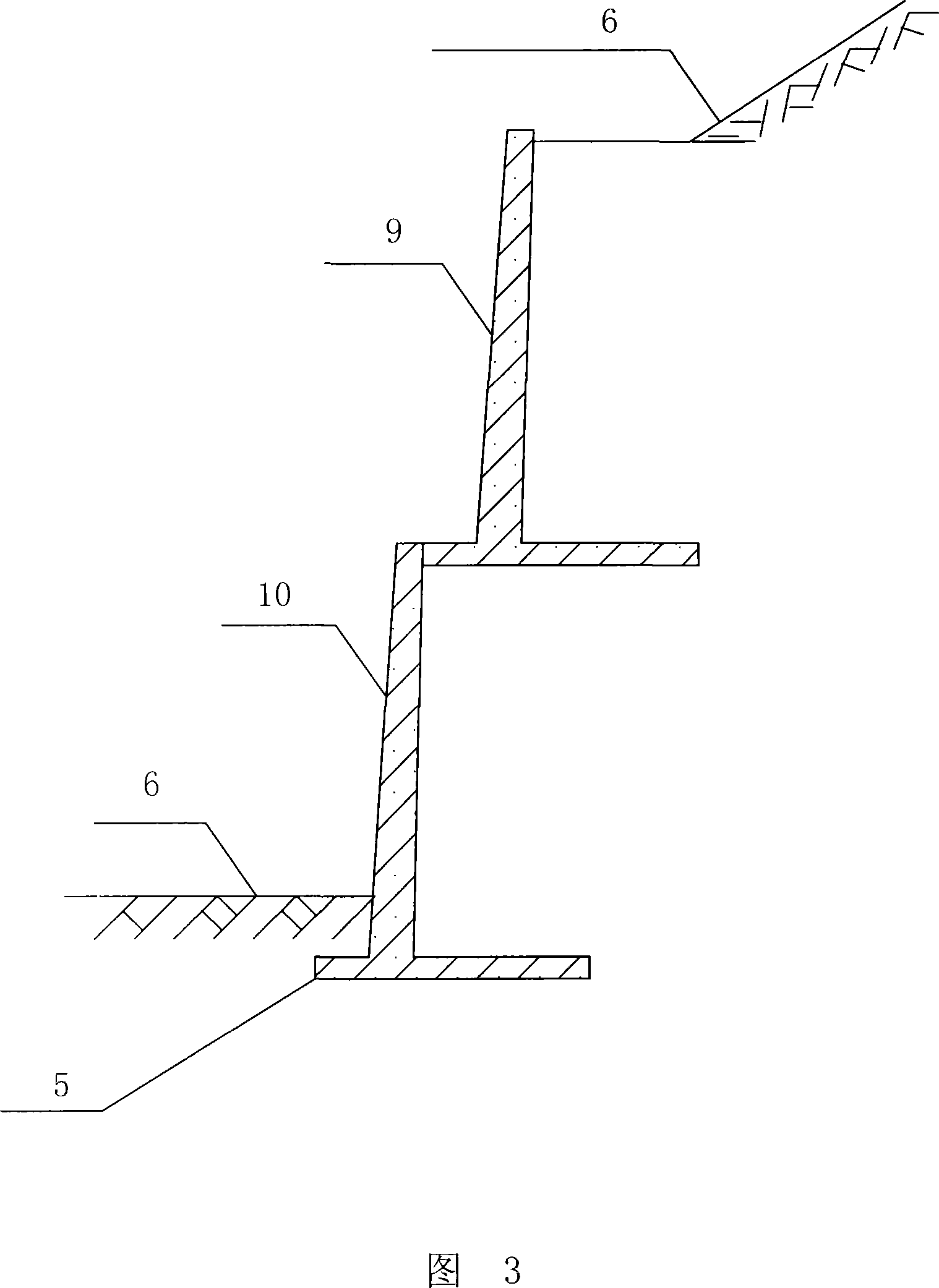

[0090] As shown in Figure 3, the single-stage cantilever retaining wall can be cast in situ or prefabricated assembled structure, and the two-stage cantilevered L-shaped retaining wall should adopt prefabricated assembled structure. When the assembled construction is adopted, firstly, the upper and lower L-shaped retaining walls are prefabricated according to the design height of the wall. The width of each unit wall can be divided into 1.0~2.0m according to the transportation capacity of the vehicle, and then transported to the construction site to complete the assembly of the retaining wall structure. Use in areas with 8 degrees.

[0091] As shown in Figure 9, the construction process mainly includes wall prefabrication, foundation trench excavation, foundation treatment, waterproof and drainage facilities, transportation and assembly of prefabricated parts, filling and compaction, landscape restoration, etc. The construction process is shown in Figure 9. 9. The difference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com