Load shedding measure of foam sheet applied to upper burying type constructional work (such as culvert)

A technology of structures and measures, which is applied in the field of geotechnical engineering, can solve problems such as heavy stress, waste of manpower and material resources, and serious cracking and diseases in culverts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]Example 1 Flood drainage tunnel for tailings dam in Heimulin, Shaanxi: The tailings filling height at the top of the cave is 60 meters, and the flood discharge structure. The original structural section was designed according to the tailings dam with a height of 40 meters. Later, due to the change of the design plan, it has been completed The strength of the flood discharge tunnels is far from satisfactory, so Party A proposes to use load reduction measures to solve it. At that time, there was no EPS board in China, so we used local straw as the flexible material for the roof of the cave for unloading. According to calculations, we filled the roof with 50 cm thick straw. After 9 and a half years of on-site testing, the roof of the cave was The vertical earth pressure is reduced by about 2 / 3, thus ensuring the long-term normal operation of the original flood discharge tunnel. (Gu An'an, Zhao Yuqiong: "Field Experimental Study on the Measures of Reducing the Vertical Earth...

Embodiment 2

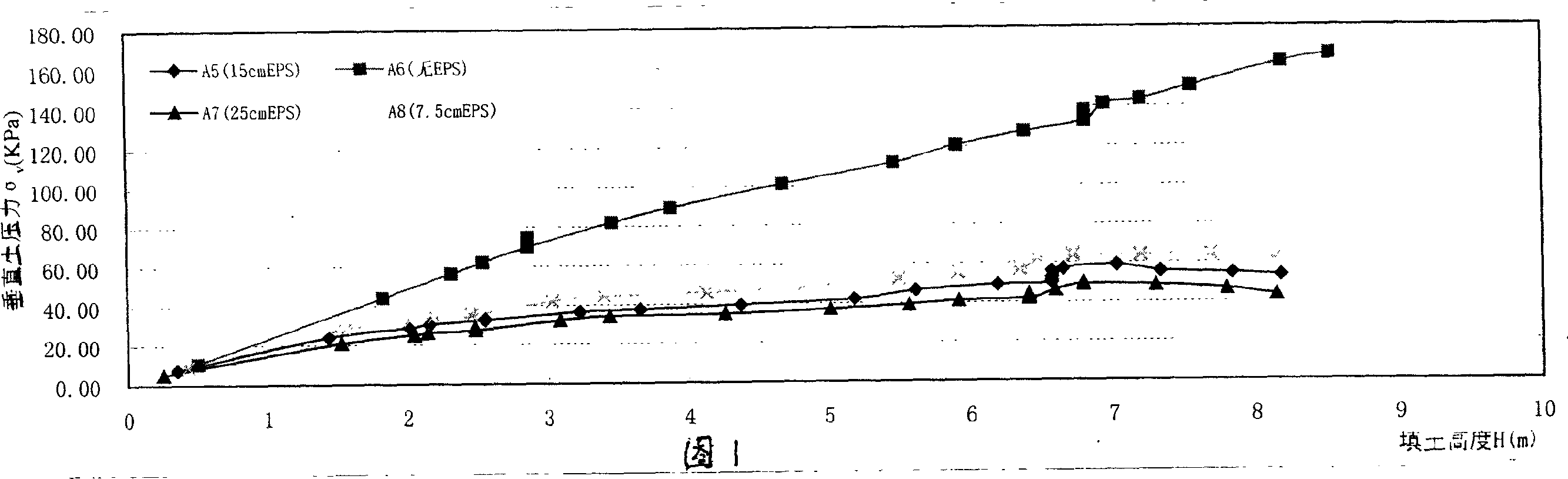

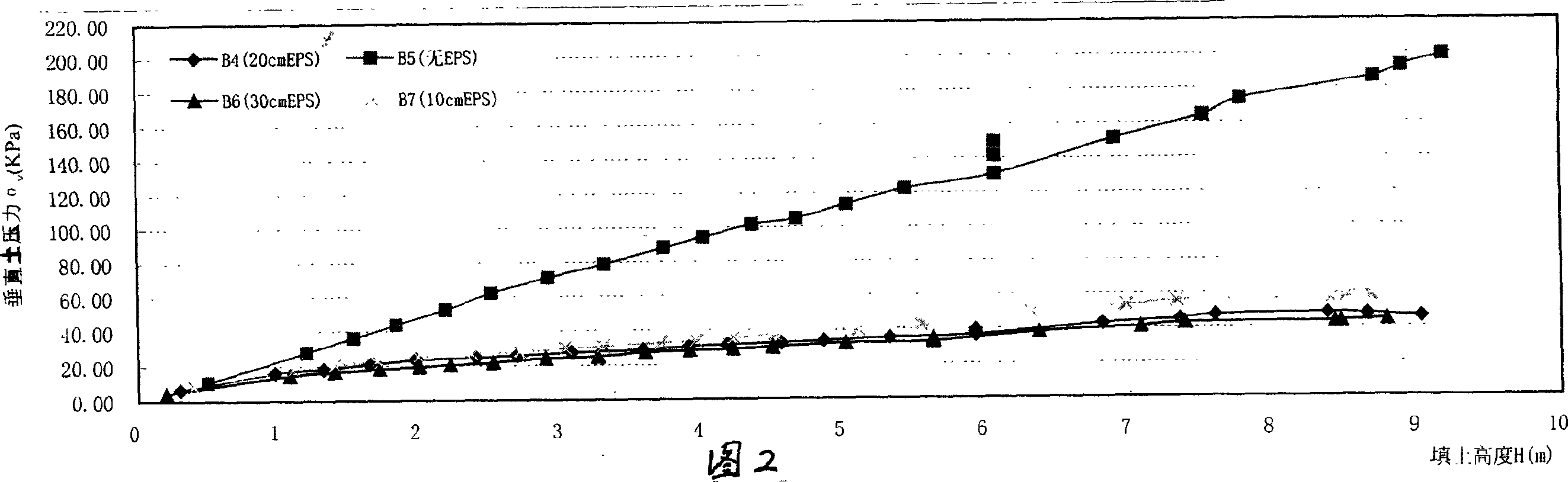

[0044] Example 2 The test culvert of Guangzhou-Huizhou Expressway in Guangdong Province has a top filling height of 32 meters and an arch culvert structure. According to the change of the top filling height, the thickness of the EPS board is selected to be 15-30 cm. According to the test observation, the vertical earth pressure on the roof of the cave is reduced by about 2 / 3. (Gu Anan, Jin Bin, Feng Ruiling: "Research on the Application of Load Reduction Measures (EPS Board Material) in High-Filled Culverts", Proceedings of the Seventh National Conference on Rock Mechanics and Engineering, August 2002).

Embodiment 3

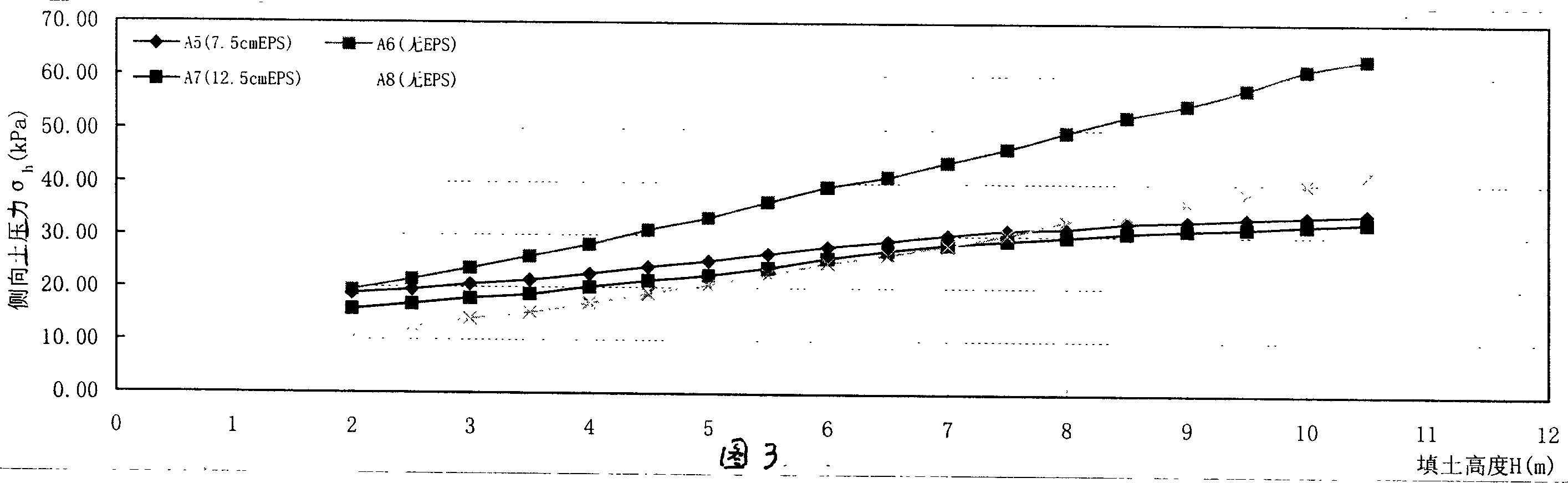

[0045] Example 3 The test culvert of South-Guangzhou Expressway in Sichuan Province, the slab culvert with the filling height of two construction sites close to 10 meters. According to the test observations in 2010, the vertical earth pressure on the roof of the cave has decreased by about 2 / 3, and the horizontal earth pressure on the side of the cave has decreased by about 1 / 2, as shown in Figure 8. (Yang Fulin, Gu An'an, Zhang Shiping, Wang Xingping: "Experimental Research on Earth Pressure, Deformation and Load Reduction Measures of Highly Filled Culverts", November 2003).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com