Multi-pile stepped retaining structure combined with manual filling soil grouting-reinforcement technology and construction method of multi-pile stepped retaining structure

A technology of grouting reinforcement and support structure, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems of inability to effectively protect adjacent structures, unsuitable anchor-pull structure, insufficient effective anchoring length, etc. Protecting mechanical properties, reasonable force, and the effect of reducing the size of the pile body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

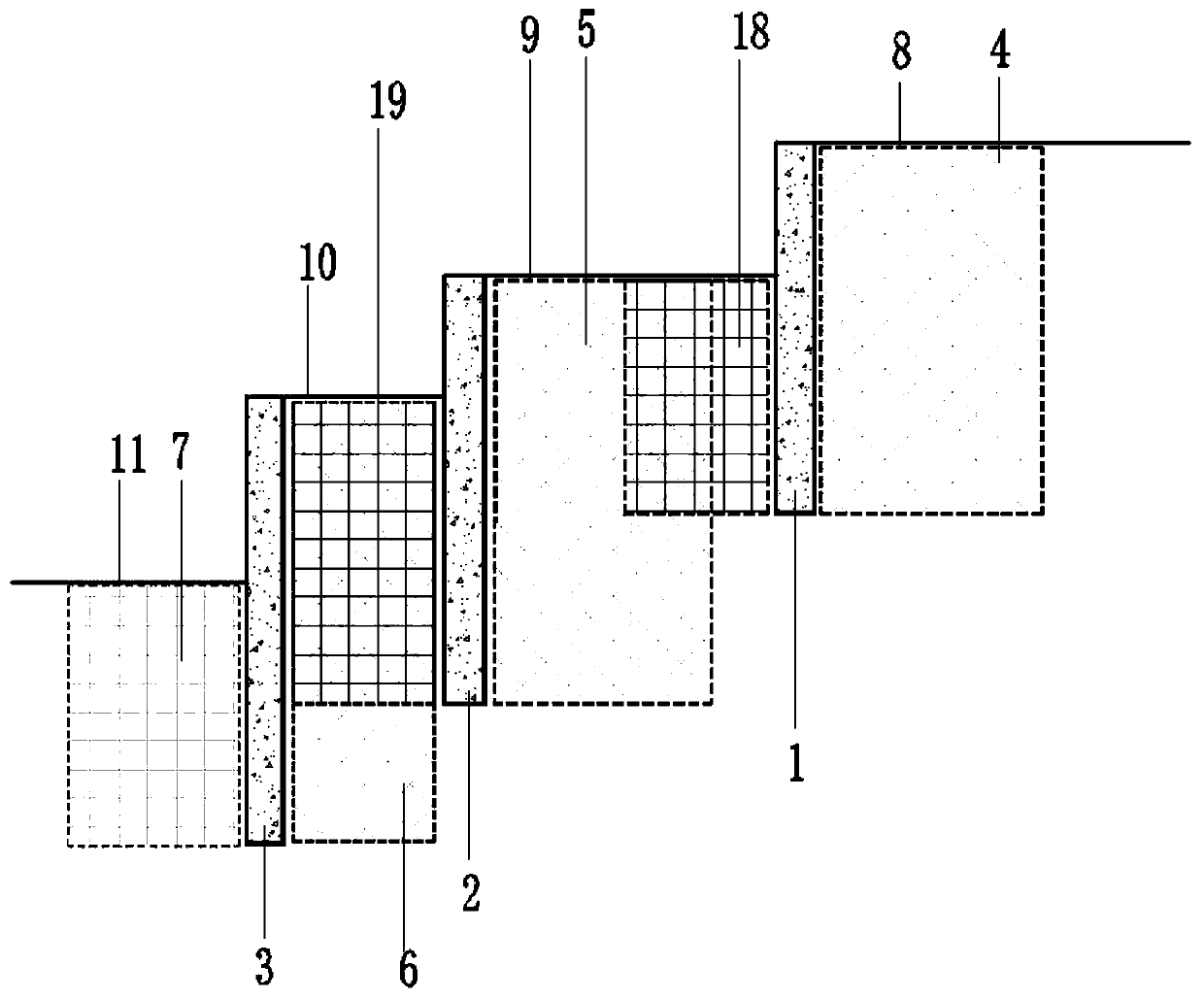

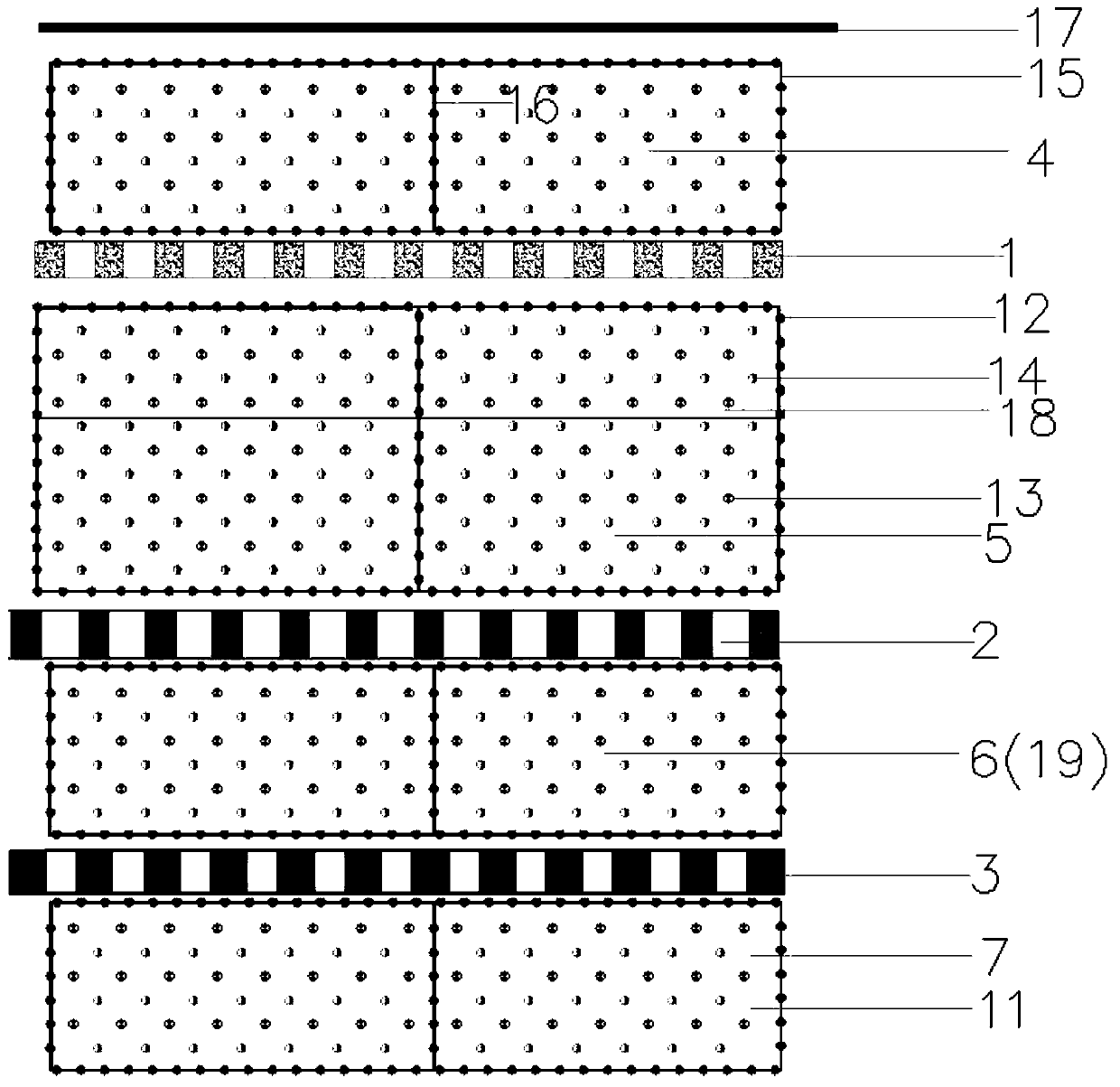

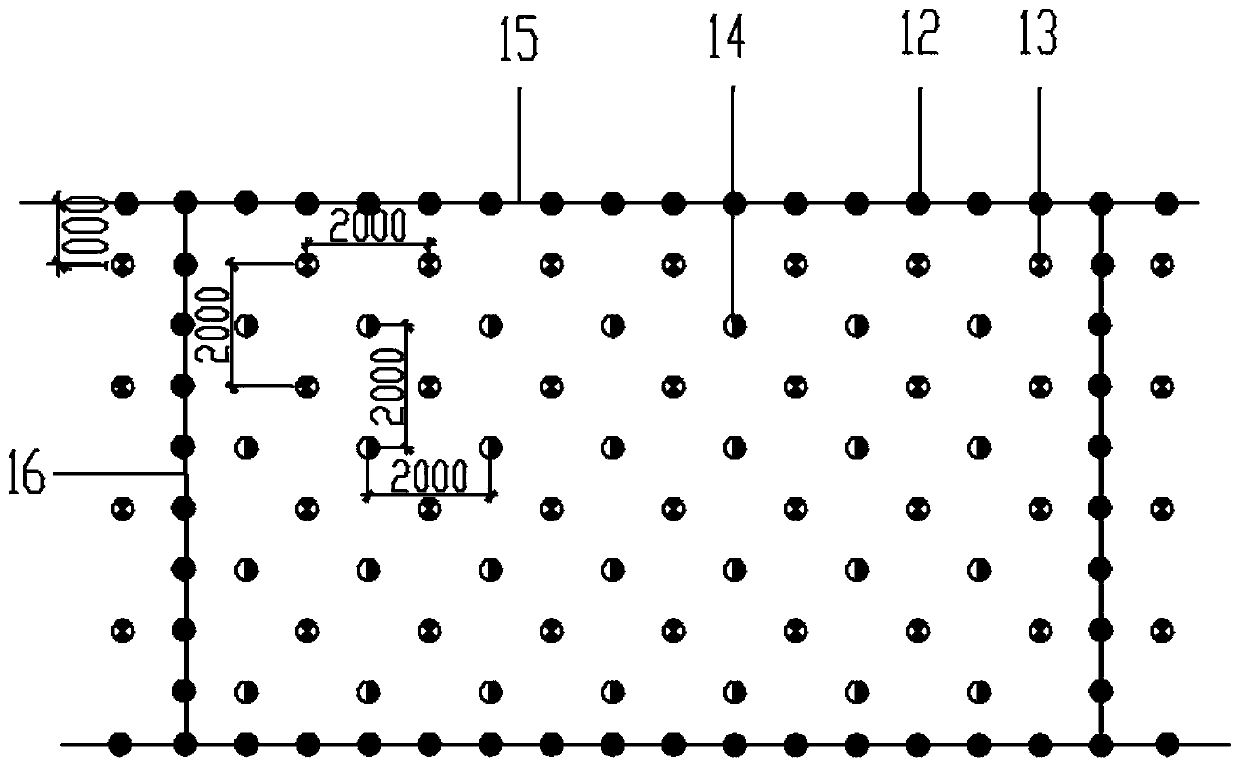

[0048] Such as figure 1 and figure 2 As shown, a multi-pile stepped retaining structure combined with artificial filling and grouting reinforcement technology provided by the present invention includes first-order side slopes 8, second-order side slopes 9 and third-order side slopes 10 of different heights, and the first-order side slopes First-order support piles 1 are provided on the slope 8 at intervals of 2.5m; on the second-order slope 9, second-order support piles 2 are arranged at intervals of 2.8m; Supporting pile 3, the rear grouting area on the side of the first-order supporting pile 1 is the first grouting area 4, the rear grouting area on the side of the second-order supporting pile 2 is the second grouting area 5, and the third-order supporting pile The rear grouting area on one side of the retaining pile 3 is the third grouting area 6, the front grouting area of the third-step support pile 3 is the fourth grouting area 7, and the front grouting area on the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com