Construction method of hard soil field PCC pile

A construction method and hard soil technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficulty in sinking molds, rise of pile core soil, etc., achieve easy pile sinking, reduce soil extrusion pressure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

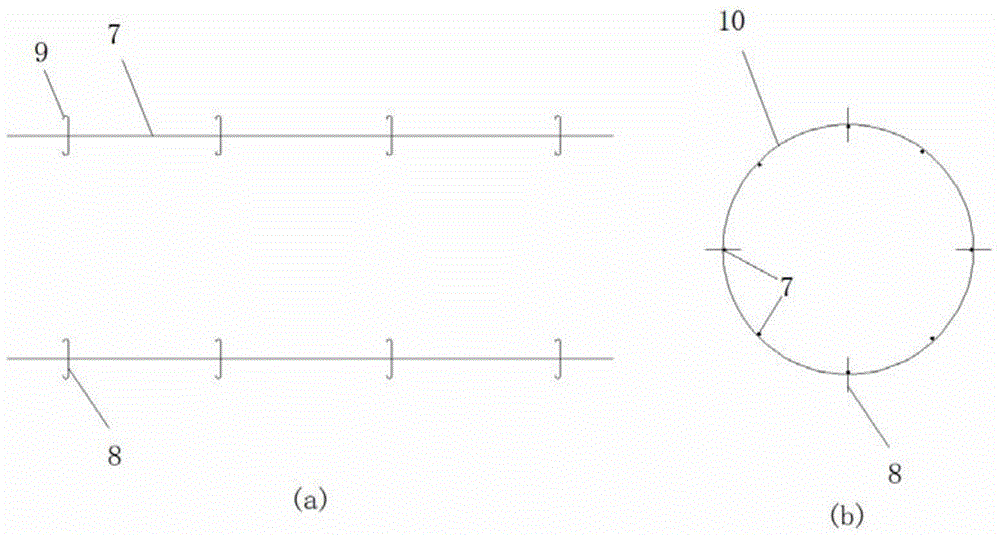

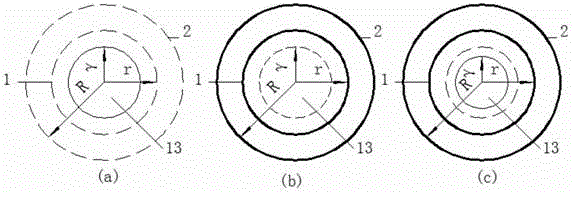

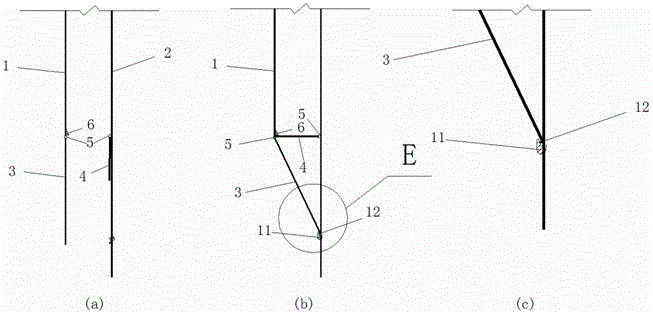

[0027] Such as figure 1 As shown in (a), before the pile driver is in place, soil is taken from the center of the pile to form a reserved cavity 13 . Reserve cavity 13 sectional areas (as figure 2 (a) The area of the small circle) and the area between the inner and outer tubes of the pile (such as figure 2 (a) The area of the circle formed by the two dotted lines) is equal, and the depth is the same as the maximum depth of sinking of the inner pipe 1 of the pile form, at this time figure 1 The section diagrams along the lines C-C and D-D are as follows figure 2 As shown in (a), the dotted line indicates the position of the pile formwork. At this time, the pile foundation is not in place yet, and the small circle with the solid line in the center indicates the outer contour of the reserved cavity 13 . Such as figure 1 As shown in (b), before the pile foundation is in place, the pile formwork is assembled and the spud cans are closed. The switch control that clamp 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com