Method for restraining deformation of existing cutting gravity type retaining wall

A gravity-type retaining wall technology, applied in buildings, artificial islands, geometric CAD, etc., can solve the problems of not considering the bearing capacity of existing cutting gravity-type retaining walls and low economic efficiency, so as to avoid demolition and reconstruction and improve economic efficiency , the effect of quick disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

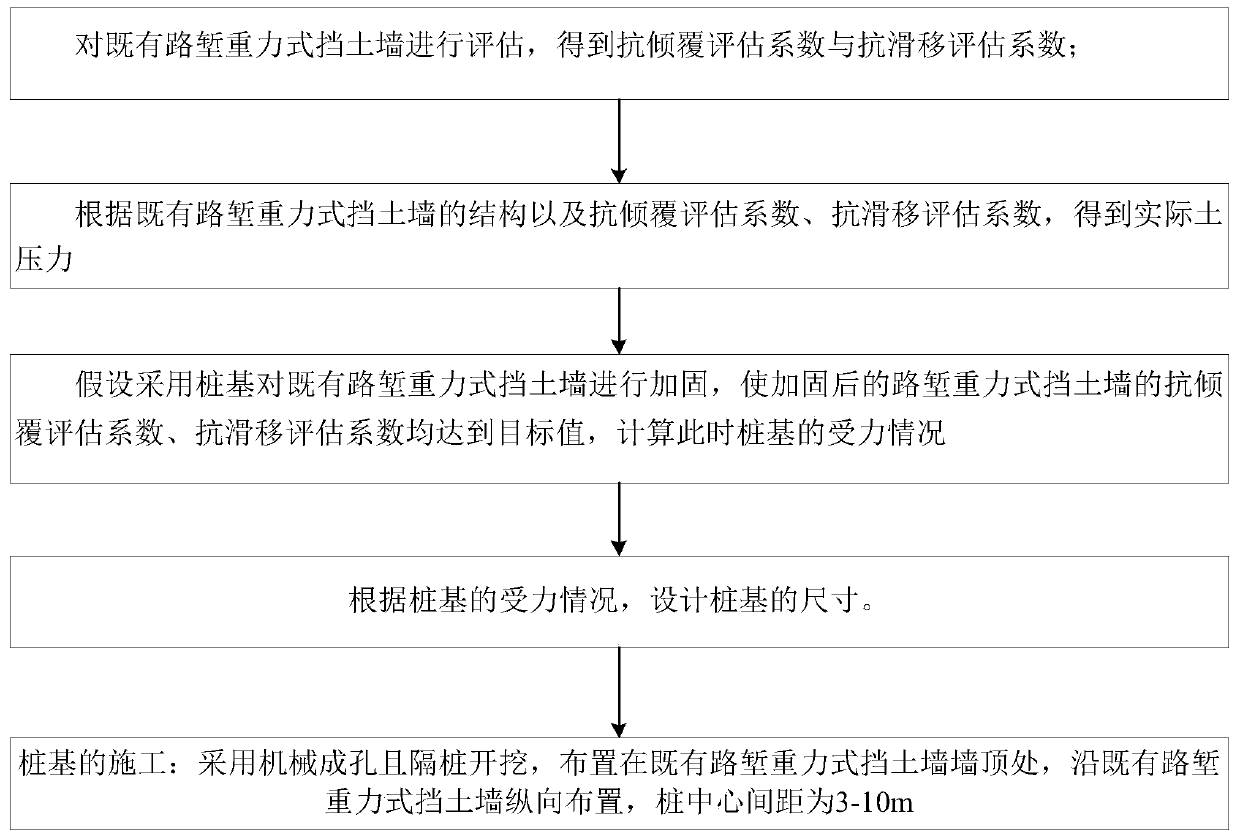

[0058] Such as figure 1 , a method for suppressing deformation of an existing cutting gravity retaining wall 1, comprising:

[0059] S100 evaluates the existing cutting gravity retaining wall 1 to obtain the actual anti-overturning evaluation coefficient and the actual anti-sliding evaluation coefficient;

[0060] S200 Obtain the actual earth pressure according to the structural force of the existing cutting gravity retaining wall 1, the actual overturning resistance evaluation coefficient, and the actual anti-slip evaluation coefficient;

[0061] S300 assumes that pile foundations are used to reinforce the existing gravity retaining wall 1 of the cutting, so that the target anti-overturning evaluation coefficient and target anti-slip evaluation coefficient of the reinforced cutting gravity retaining wall can be used to calculate the stress of the pile foundation;

[0062] S400 designs the size of the pile foundation according to the force condition of the pile foundation.

...

Embodiment 2

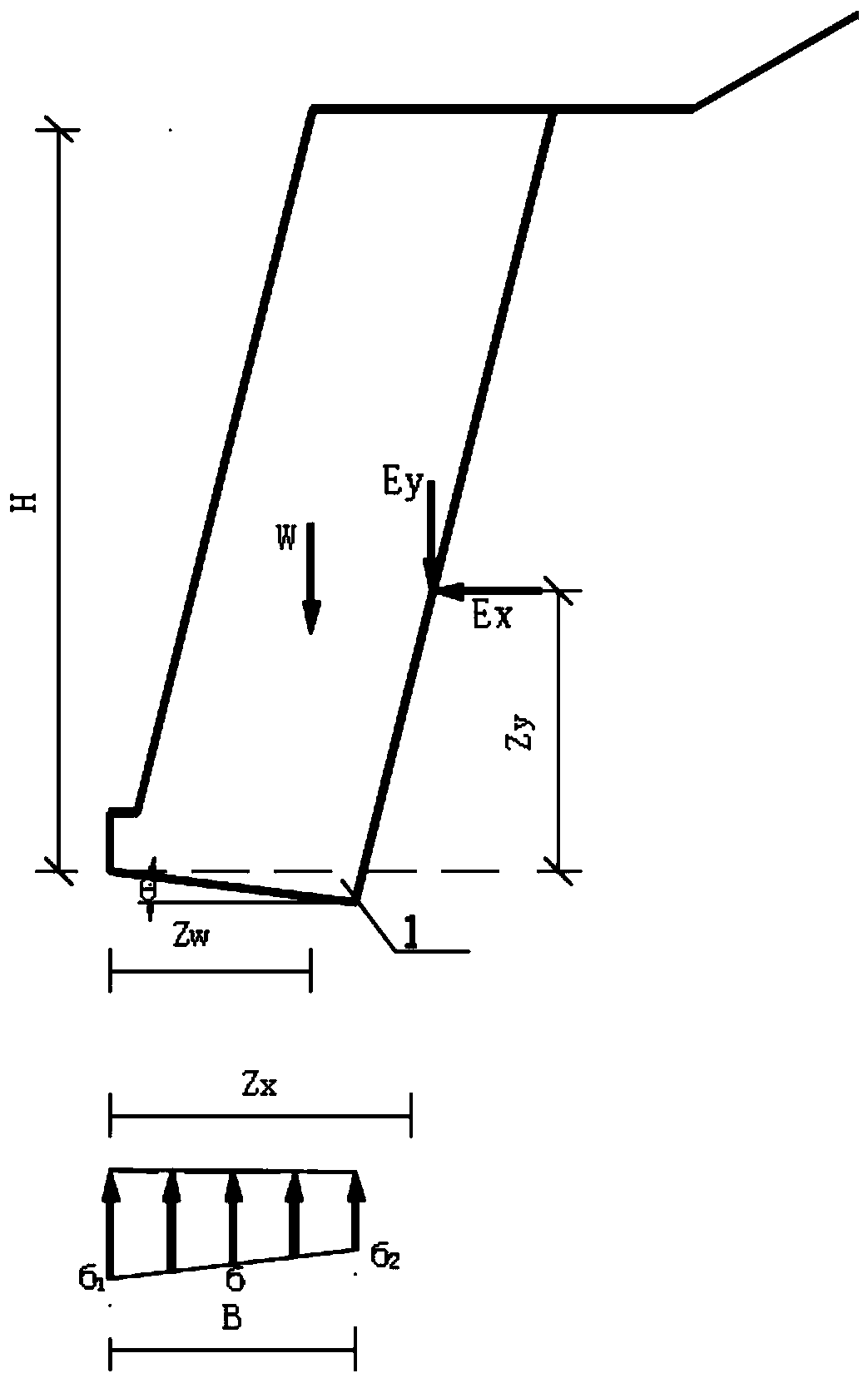

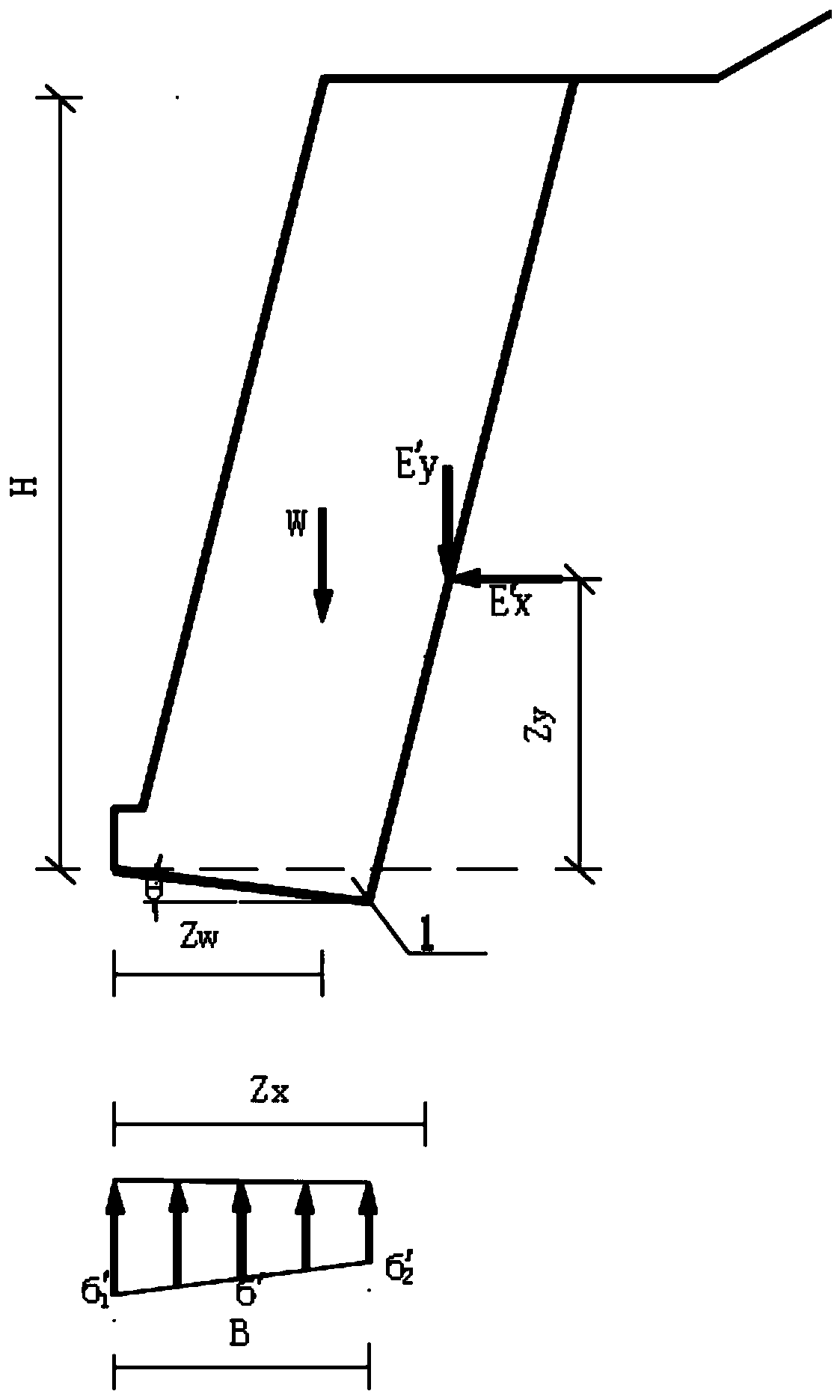

[0140] The first step is to evaluate the gravity retaining wall 1 of the existing road cutting

[0141] Such as Figure 7 , it is known that there is an existing cut gravity retaining wall 1 of a single-line Class I railway, the retaining wall is 6.0m high and 1.4m buried deep. The back slope slope is 1:-0.25, the wall toe step width is 0.25m, the wall toe step height is 0.6m, the wall toe step is the same as the wall slope, the wall bottom slope ratio is 0.200:1, and the base friction coefficient f is 0.3, see for details Image 6 . The original design anti-overturning stability safety factor is 2.1847, and the original design anti-sliding stability safety factor is 1.316.

[0142] According to the safety assessment method and means, the anti-overturning and anti-sliding stability of the existing cutting gravity retaining wall 1 is evaluated, and the anti-overturning and anti-sliding evaluation coefficients K are respectively obtained 02 = 1.5 and K C2 = 1.1.

[0143] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com