Method for reducing side load influence

A technology of side load and side wall, applied in the direction of excavation, filling, water conservancy projects, etc., can solve the problems of increasing tensile force on the top surface of the bottom plate and uneven settlement, etc., and achieve the effect of eliminating the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

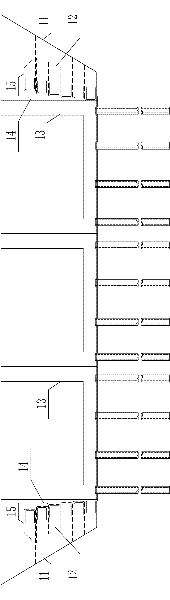

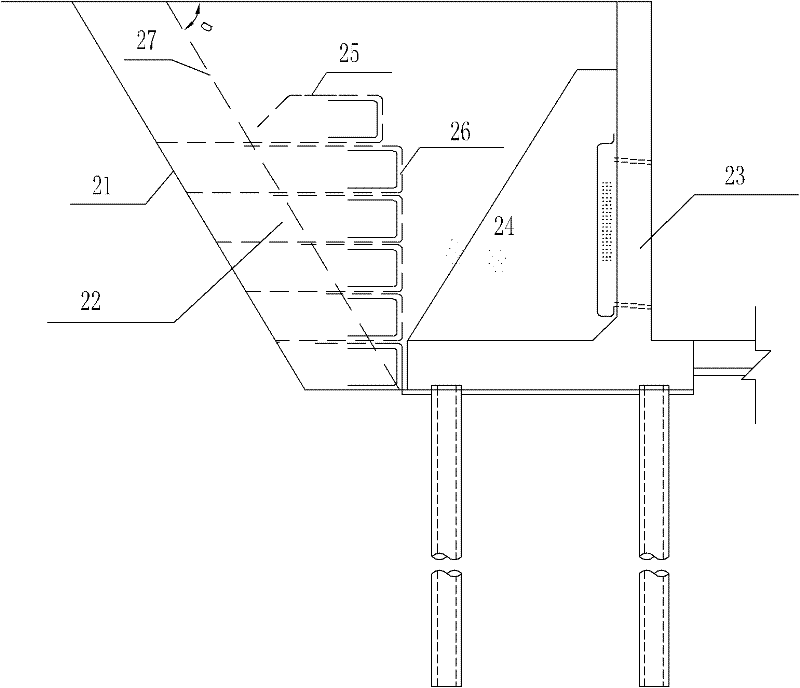

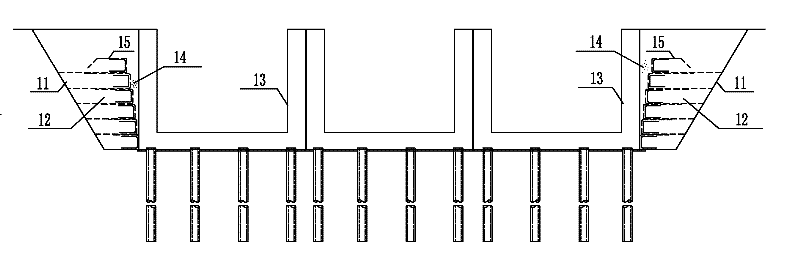

[0024] combine figure 1 The method for reducing the influence of side loads involved in the present invention will be further described. figure 1 It is a schematic diagram of construction using this method. This method is carried out successively as follows:

[0025] (1) Normal grading excavation of foundation pit (see figure 1 middle excavation face 11);

[0026] (2) At the position close to the side wall of the main structure 13, backfill soil is constructed in advance to form an approximate vertical slope 12;

[0027] (3) main structure 13 construction;

[0028] (4) The gap between the structural side wall and the vertical slope is filled ( figure 1 The middle is backfill soil 14).

[0029] In the past, the construction of backfill soil is usually carried out after the construction of the main structure, but in this invention, the backfill soil should be done before the construction of the main structure, the earlier the better, so that the preloading of the foundatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com