Photo-electromagnetic response epoxy glass polymer

An epoxy-based, opto-electromagnetic technology, applied in the field of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The epoxy-type glass polymer (vitrimer) of photoelectromagnetic response of the present invention is made of 50-80 parts of epoxy resin, 20-40 parts of epoxy curing agent, 0 part of epoxy diluent, 5 parts of inorganic Filler and 5 parts of catalyst composition.

[0022] The epoxy resin is bisphenol A diglycidyl ether, the epoxy curing agent is sebacic acid, and the inorganic filler is Fe 3 o 4 Particles, the size of which is 20nm, the catalyst is triazabicyclic.

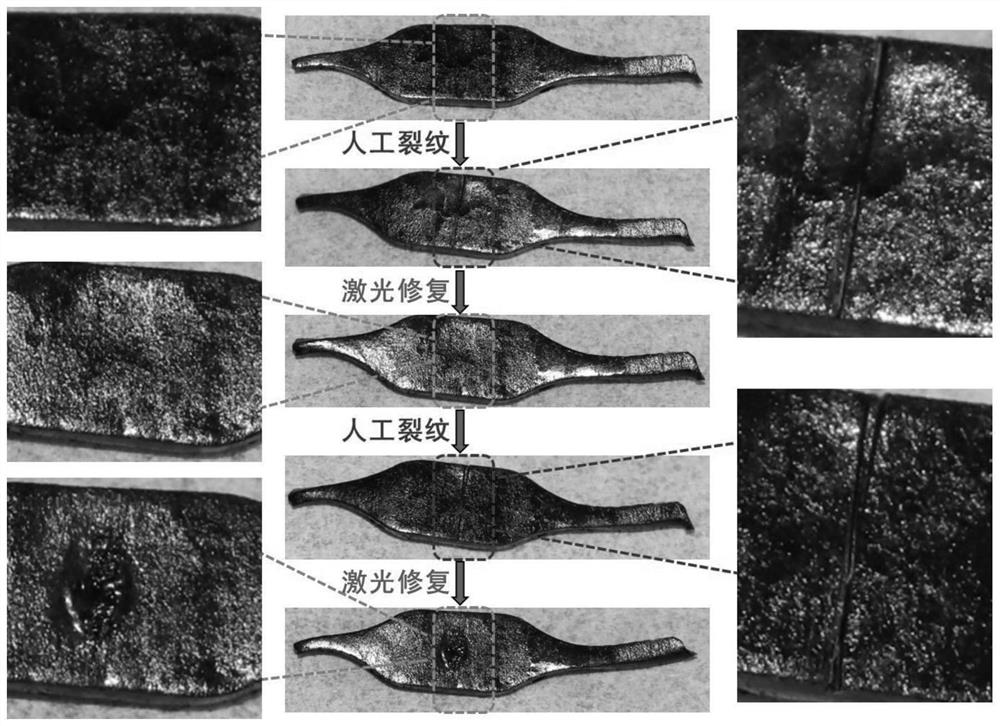

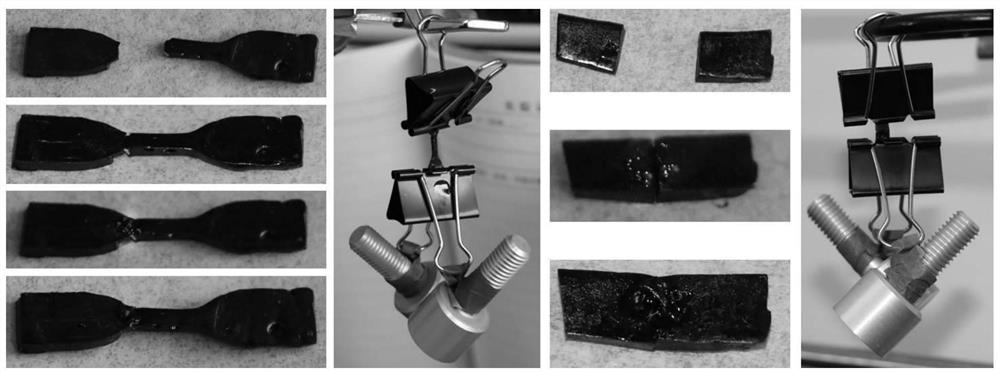

[0023] The photoelectromagnetic responsive epoxy vitrimer has thermal responsiveness, and can realize crack self-repair, welding and reprocessing at high temperature (100-300° C. and above).

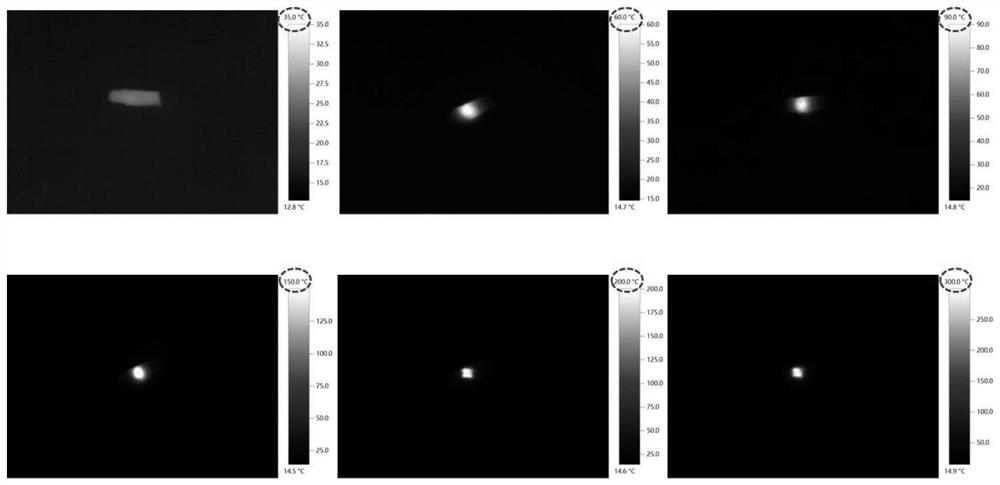

[0024] The photoelectromagnetic response epoxy vitrimer has photoresponsiveness. Under the irradiation of 808nm infrared laser, the temperature of the material rises to 100-300°C and above in a short time, which can realize the self-repair of micro-cracks and show photoresponsiveness.

[0025] The photoelectromagnetic...

Embodiment 2

[0028] The epoxy-type glass macromolecule (vitrimer) of photoelectromagnetic response of the present invention is made of 50-80 parts of epoxy resin, 20-40 parts of epoxy curing agent, 10 parts of epoxy diluent, 5 parts of inorganic Filler and 5 parts of catalyst composition.

[0029] The epoxy resin is bisphenol A diglycidyl ether, the epoxy curing agent is adipic acid, the epoxy diluent is octyl glycidyl ether, and the inorganic filler is Fe 3 o 4 Particles, the size of which is 50nm, the catalyst is zinc acetate.

[0030] The photoelectromagnetic responsive epoxy vitrimer has thermal responsiveness, and can realize crack self-repair, welding and reprocessing at high temperature (100-300° C. and above).

[0031] The photoelectromagnetic response epoxy vitrimer has photoresponsiveness. Under the irradiation of 808nm infrared laser, the temperature of the material rises to 100-300°C and above in a short time, which can realize the self-repair of micro-cracks and show photore...

Embodiment 3

[0035] The epoxy-type glass macromolecule (vitrimer) of photoelectromagnetic response of the present invention consists of 80-100 parts of epoxy resin, 40-60 parts of epoxy curing agent, 10 parts of epoxy diluent, 10 parts of inorganic filler and 0 part catalyst composition;

[0036] The epoxy resin is bisphenol F diglycidyl ether, the epoxy curing agent is 4,4-dithiodibutyric acid, the epoxy diluent is phenyl glycidyl ether, and the inorganic filler for Fe 3 o 4 Particles, the size of which is 50nm.

[0037] The photoelectromagnetic responsive epoxy vitrimer has thermal responsiveness, and can realize crack self-repair, welding and reprocessing at high temperature (100-300° C. and above).

[0038] The photoelectromagnetic response epoxy vitrimer has photoresponsiveness. Under the irradiation of 808nm infrared laser, the temperature of the material rises to 100-300°C and above in a short time, which can realize the self-repair of micro-cracks and show photoresponsiveness.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com