Method for preparing high-purity vanadium pentoxide by low-temperature chlorination of high-calcium and high-phosphorus vanadium slag

A high-calcium and high-phosphorus vanadium slag and vanadium pentoxide technology, which is applied in the fields of metallurgy and chemical industry, can solve the problems of difficulty in rectification and purification and treatment of chlorinated residues, influence on fluidized bed operation, and loss of flow from calcium chloride melting. Achieve the effect of improving economic and social benefits, good product quality, and reducing production and environmental protection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

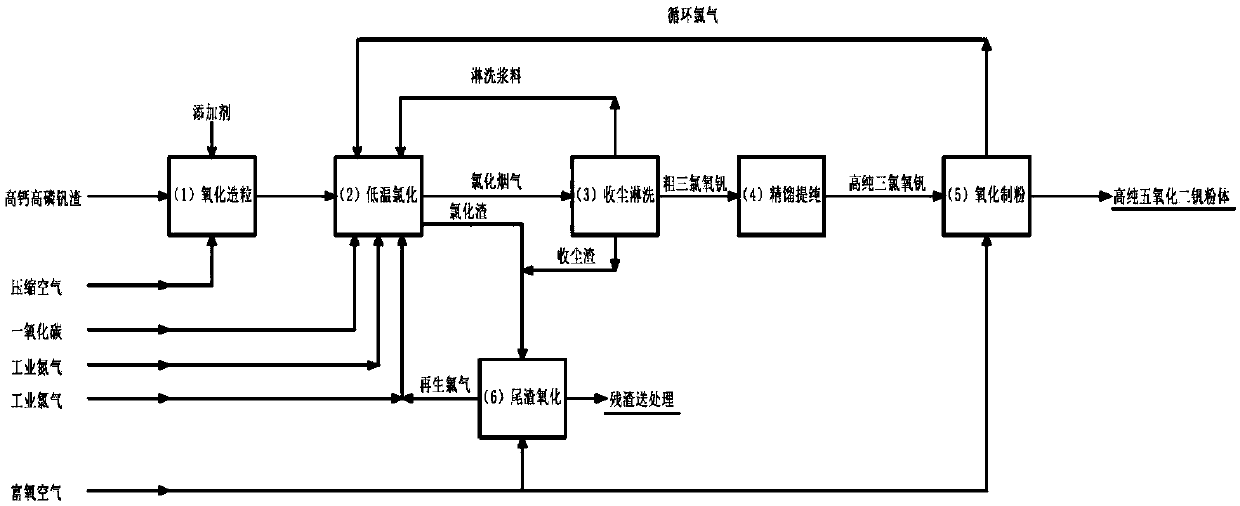

[0033] figure 1 It is a schematic flow diagram of the method for preparing high-purity vanadium pentoxide by low-temperature chlorination of high-calcium, high-phosphorus vanadium slag according to the present invention.

[0034] Calculated in terms of equivalent oxides, the composition of a typical high-calcium, high-phosphorus vanadium slag is as follows: 18%V 2 O 5 ,27%CaO,17%FeO,4%P 2 O 5 ,11%SiO 2 ,8%TiO 2 ,4%Al 2 O 3 ,5%MgO,4%MnO,2%Cr 2 O 3 .

[0035] Combine figure 1 The method for preparing high-purity vanadium pentoxide by low-temperature chlorination of high-calcium, high-phosphorus vanadium slag used in this embodiment includes an oxidation granulation step 1, a low-temperature chlorination step 2, a dust collection and washing step 3, and a distillation The six processes of purification process 4, oxidation powder making process 5 and tailings oxidation process 6 are specifically carried out as follows:

[0036] 1) The high-calcium, high-phosphorus vanadium slag and add...

Embodiment 2

[0043] In this embodiment, the method for preparing high-purity vanadium pentoxide described in embodiment 1 is adopted, and fly ash is used as the raw material rich in silica, the silica content is 20%, and the addition ratio of fly ash is 90% of the mass of vanadium slag; The operating temperature of the oxidation granulation step 1 is 600°C, and the reaction time is 300 minutes; the low-temperature chlorination step 2 uses a fluidized bed reactor, the chlorination temperature is 300°C, and the molar ratio of carbon monoxide to chlorine is 1.5; A fluidized bed reactor is used in the oxidation powder making step 5, the oxidation temperature is 150°C, the molar ratio of catalyst pure water to vanadium oxychloride is 0.15, and the molar ratio of oxygen to vanadium oxychloride in oxygen-enriched air is 0.90; In the tailings oxidation step 6, a fluidized bed reactor is used, the reaction temperature is 300° C., and the residence time is 180 min. The recovery rate of vanadium in th...

Embodiment 3

[0045] In this embodiment, the method for preparing high-purity vanadium pentoxide described in embodiment 1 is adopted, quartz sand is used as the raw material rich in silica, the silica content is 80%, and the addition ratio of quartz sand is 10% of the mass of the vanadium slag; The operating temperature of the oxidation granulation step 1 is 1000°C, and the reaction time is 60 minutes; the low-temperature chlorination step 2 uses a fluidized bed reactor, the chlorination temperature is 700°C, and the molar ratio of carbon monoxide to chlorine is 1.0; In the pulverizing step 5, a fluidized bed reactor is used, the oxidation temperature is 600°C, the molar ratio of catalyst pure water to vanadium oxychloride is 0.01, and the molar ratio of oxygen to vanadium oxychloride in the oxygen-enriched air is 0.75; In the tailings oxidation step 6, a fluidized bed reactor is used, the reaction temperature is 1000°C, and the residence time is 30 minutes. The recovery rate of vanadium in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com