Two-sided synchronous high-efficiency milling and casting machine tool for impeller vane

A grinding and polishing blade technology, applied in grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of flutter, blade processing precision reduction, single tool head, etc., to improve adaptability, improve grinding and polishing efficiency, Avoid the effect of processing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

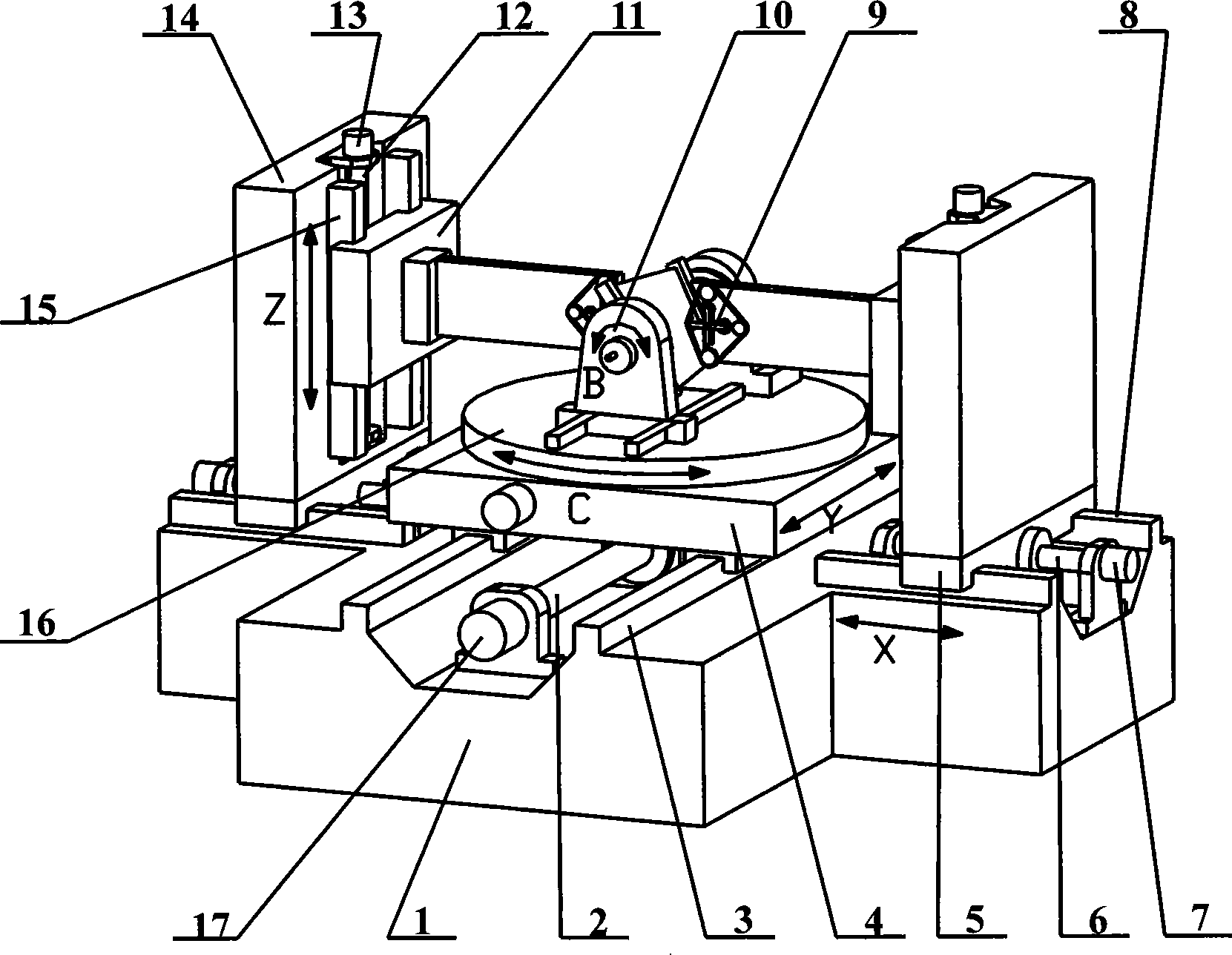

[0022] The Y-direction moving mechanism and two X-direction moving mechanisms are fixed on the bed 1, and the two X-direction moving mechanisms are coaxial and form a symmetrical horizontal and vertical distribution with the Y-direction moving machine; two abrasive belt variable wheel system grinding and polishing tool systems 9 Are respectively connected to two Z-direction moving mechanisms; the two Z-direction moving mechanisms are respectively connected to two uprights 14; the two uprights are respectively connected to two X-direction moving mechanisms; the turning jig 10 is installed on the rotary table 16, the The turning fixture can realize the clamping of the blade and the rotation of the blade around the central axis B of the turning fixture; the rotary table is connected with the Y-direction moving mechanism, and the rotary table provides rotation about its central axis C axis.

[0023] The present invention will be described in further detail below with reference to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com