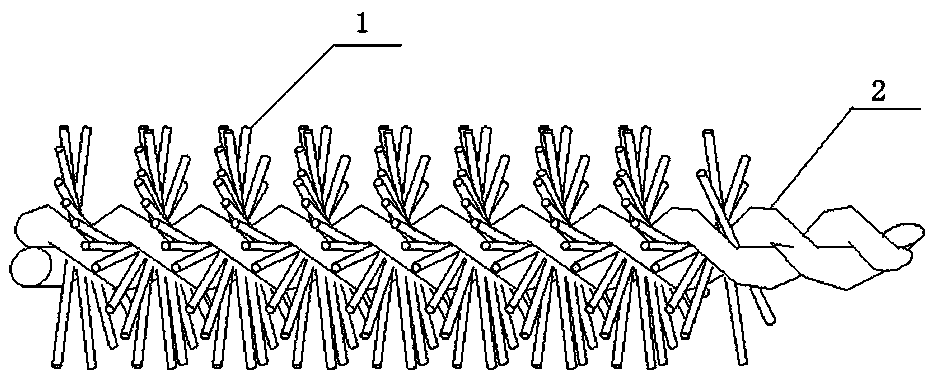

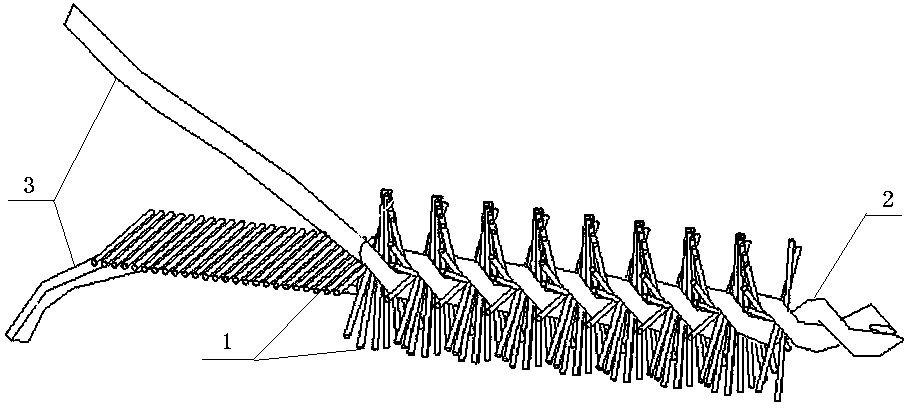

Buffing wheel based on fiber ropes containing chopped fibers and production method of buffing wheel

A technology of chopped fibers and polishing wheels, which is applied in the field of polishing wheels, can solve the problems of rising surface temperature of polishing wheels, blackening of the surface of adhesive failure, shortening service life of polishing wheels, etc., so as to improve structural strength and improve interlayer Peeling, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] .

[0036] Sample making

[0037] 1.1 Process route

[0038] 1.2.1 Glue on the hemp rope: roll a circle of glue on the treated sisal fiber rope (: 65% modified liquid phenolic resin solution, filler: 35%, glue solid content: 75-77% , the amount of glue is: 0.7-0.8g per gram of sisal fiber rope), and then baked at 70±2°C for 30min.

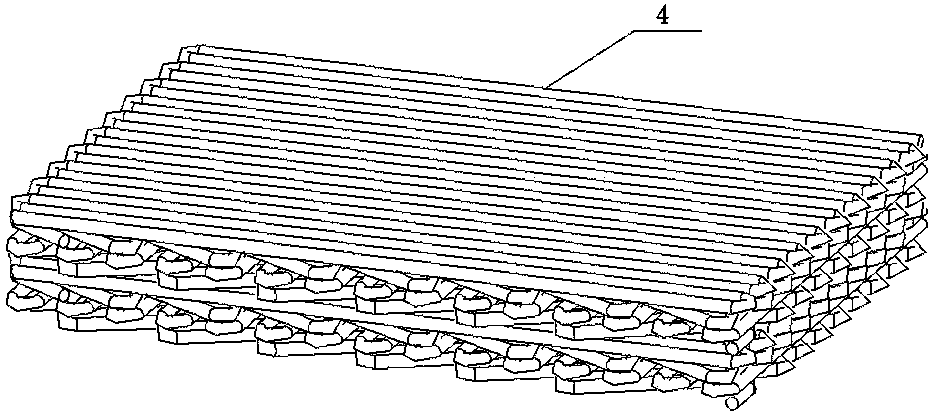

[0039] 1.2.2 Wrap the glued fiber rope on the mold according to the established route, then put it into the mold cavity, press and set it, bake it at 120°C for 4-6 hours (the flat polishing wheel is cured for 4 hours, and the circumferential polishing wheel is cured 6h), after slowly cooling down to room temperature, take it out of the oven, and remove the mold.

[0040] 1.3 The samples produced for this test are: plane polishing wheel: outer diameter is 4 inches (101.6-103mm), inner diameter is 55mm, hole diameter is 16mm, thickness is 6-8mm); circular polishing wheel: outer diameter is 10.6 inches (270mm), hole diameter is 32mm, thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com